A solvent-free polyaspartate heavy-duty anti-corrosion coating with a combination of bottom and surface, its preparation method and its application

An aspartic acid ester and aspartic acid technology, applied in the direction of polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve the problems of increasing construction uncontrollability, increasing construction costs, and high parking and maintenance costs, achieving The spraying ratio is stable, the curing rate is fast, and the construction efficiency is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

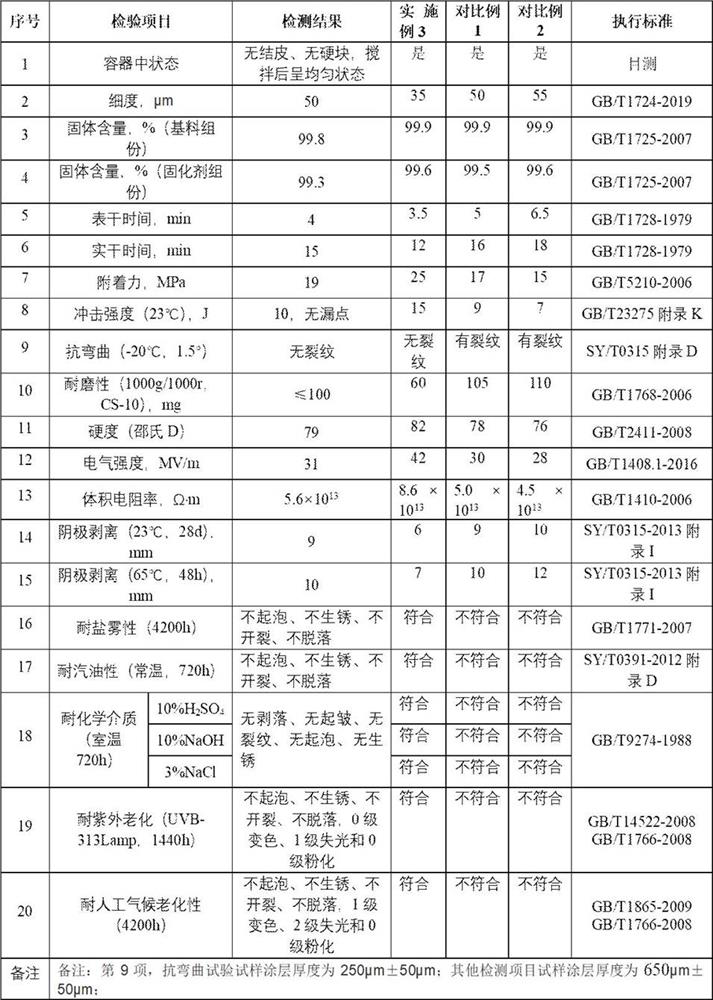

Examples

preparation example Construction

[0046] In one embodiment of the present invention, the preparation method of the modified filler includes the following steps: (1) dissolving the silane coupling agent in absolute ethanol to prepare a solution with a mass concentration of 30-50%; (2) dissolving the The solution is sprayed on the filler in a high-speed mixer, stirred evenly at a high speed, dried in a blast drying oven at 100-105° C. for 2-5 hours, and then cooled naturally to obtain a modified filler.

[0047] In one embodiment according to the present invention, the silane coupling agent is γ-aminopropyltrimethoxysilane, N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane, N-( One or a combination of β-aminoethyl)-γ-aminopropyltriethoxysilane and anilinomethyltrimethoxysilane.

[0048] In an embodiment according to the present invention, the preparation method of the hyperbranched modified aspartic acid resin comprises the following steps: (1) In a reactor protected by an inert gas, add three Chlorosilane ethanol...

Embodiment 1

[0064] (1) prepare hyperbranched modified aspartic acid resin:

[0065] (1) Add trichlorosilane ethanol solution with a mass concentration of 10-30% in a nitrogen-protected reactor, and add deionized water drop by drop under stirring. The molar ratio of deionized water to trichlorosilane is 1:3. React at a temperature of 75°C for 0.5 hours, then add hexamethylene diisocyanate, and continue to react for 0.5 hours to obtain a pre-reaction liquid; Add hexamethylenediamine dropwise to the pre-reaction solution to end capping to obtain a silicon block branched modified organic diamine reaction solution; (3) use titration in the above silicon block branched modified organic diamine reaction solution Dimethyl maleate was slowly added dropwise into the funnel. After the dropwise addition, the temperature was raised to 90°C for constant temperature reaction for 10 hours, then the solvent was removed and recovered, and the degree of reaction was determined by mercaptan-iodine titration ...

Embodiment 2

[0072] (1) prepare hyperbranched modified aspartic acid resin:

[0073] (1) In a nitrogen-protected reactor, add trichlorosilane ethanol solution with a mass concentration of 30%, and add deionized water drop by drop under stirring. The molar ratio of deionized water to trichlorosilane is 1:3. React at 85°C for 1 hour, then add isophorone diisocyanate, and continue to react for 1 hour to obtain a pre-reaction liquid; Add 2,2,4-trimethyl-1,6-butanediamine dropwise to the pre-reaction solution to obtain a silicon block branched modified organic diamine reaction solution; (3) in the above silicon block branched Diethyl maleate was slowly added dropwise into the chemically modified organic diamine reaction solution with a titration funnel. After the dropwise addition, the temperature was raised to 100°C for constant temperature reaction for 15 hours, and then the solvent was removed and recovered, and determined by mercaptan-iodine titration analysis method The degree of reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com