Infrared optimal regeneration temperature device for soot particle filter of diesel engine

A technology of filtration regeneration and regeneration temperature, which is applied in the direction of mufflers, exhaust devices, mechanical equipment, etc., can solve problems such as unsatisfactory effects, achieve the effect of increased protection, convenient pick and place, and improve the efficiency of electric energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

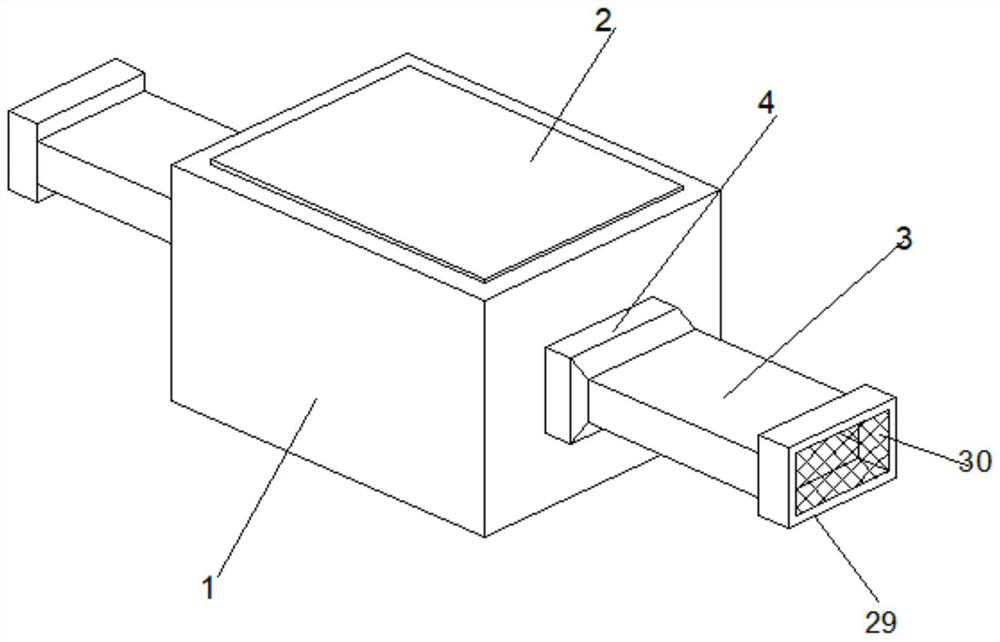

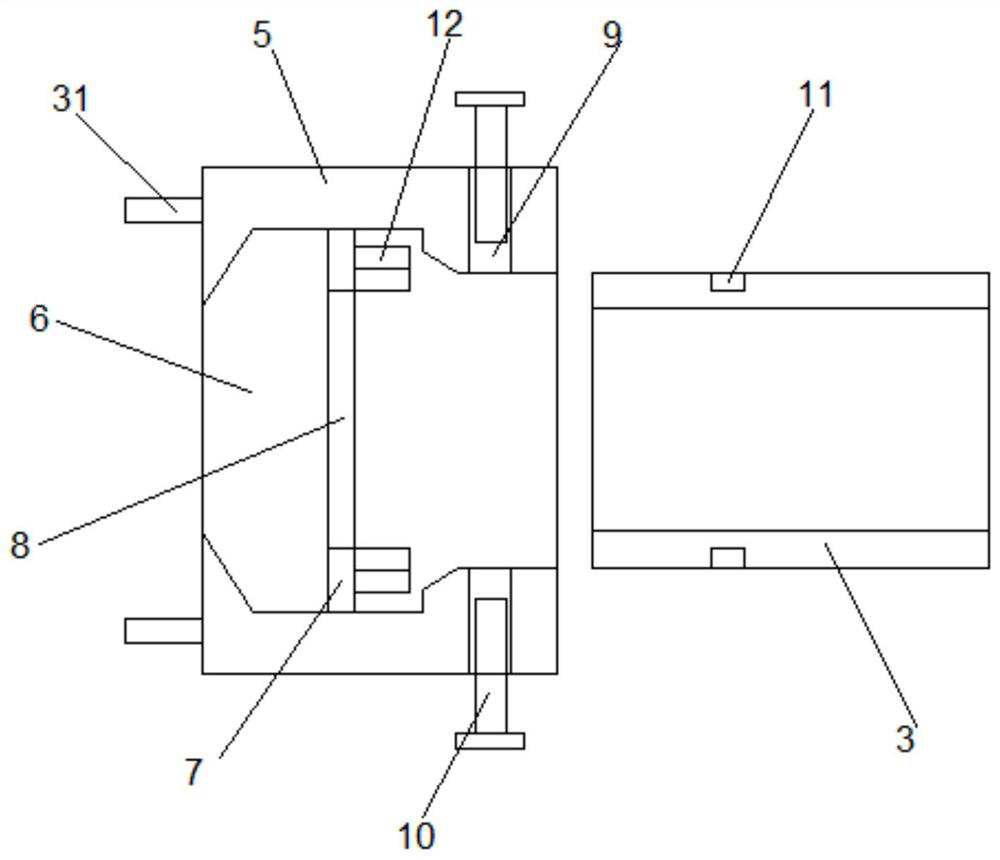

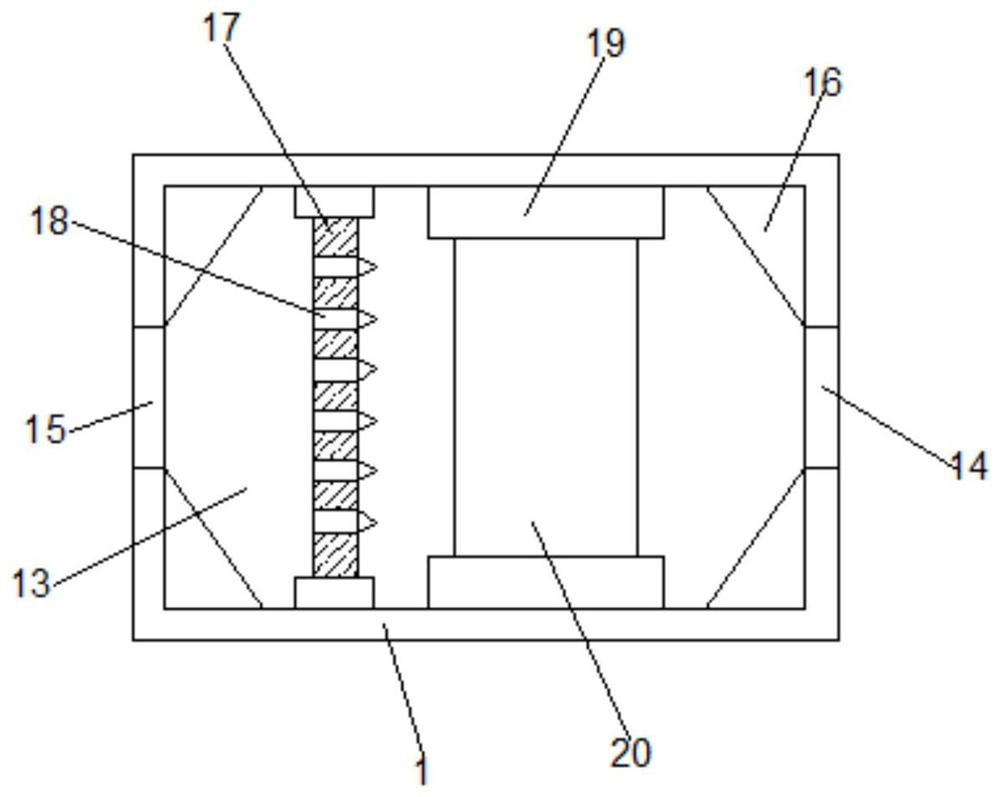

[0038] see Figure 1-7According to an embodiment of the present invention, an infrared optimal regeneration temperature device for a diesel soot particle filter body includes a filter regeneration chamber 1, and a sealing cover 2 is detachably provided on the filter regeneration chamber 1, and the filter regeneration chamber 1 Connecting pipes 3 are installed at both ends through a connecting structure 4, the connecting structure 4 includes a connecting shell 5, and an inner cavity 6 is arranged inside the connecting shell 5, and a limiting partition 7 is fixed inside the inner cavity 6, The limit partition 7 is provided with an opening 8, the upper and lower sides of the inner cavity 6 are provided with threaded holes 9, and the threaded holes 9 are provided with threaded rods 10, and the upper and lower sides of the connecting pipe 3 are A connecting thread groove 11 matching the threaded hole 9 is provided, and the limiting partition plate 7 is located on one side of the co...

Embodiment 2

[0041] Such as figure 2 As shown, the filter regeneration chamber 1 is detachably provided with a sealing cover 2, and the two ends of the filter regeneration chamber 1 are equipped with connecting pipes 3 through the connection structure 4, the connection structure 4 includes a connection shell 5, and the connection The housing 5 is provided with an inner cavity 6, the inner cavity 6 is fixed with a spacer partition 7, the spacer spacer 7 is provided with an opening 8, and the upper and lower sides of the inner cavity 6 are provided with Threaded hole 9, threaded rod 10 is arranged in described threaded hole 9, and the upper and lower sides of described connecting pipeline 3 are all provided with connecting threaded groove 11 that matches with described threaded hole 9, and described limit partition 7 is positioned at the One side of the connecting pipe 3 is symmetrically provided with a position-limiting sealing structure 12, and a filter regeneration cavity 13 is provided ...

Embodiment 3

[0043] Such as Figure 6 As shown, the filter regeneration chamber 1 is detachably provided with a sealing cover 2, and the two ends of the filter regeneration chamber 1 are equipped with connecting pipes 3 through the connection structure 4, the connection structure 4 includes a connection shell 5, and the connection The housing 5 is provided with an inner cavity 6, the inner cavity 6 is fixed with a spacer partition 7, the spacer spacer 7 is provided with an opening 8, and the upper and lower sides of the inner cavity 6 are provided with Threaded hole 9, threaded rod 10 is arranged in described threaded hole 9, and the upper and lower sides of described connecting pipeline 3 are all provided with connecting threaded groove 11 that matches with described threaded hole 9, and described limit partition 7 is positioned at the One side of the connecting pipe 3 is symmetrically provided with a position-limiting sealing structure 12, and a filter regeneration cavity 13 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com