Normal-temperature active milk and preparation method thereof

An active and milk technology, applied in the direction of milk preparations, dairy products, milk preservation, etc., can solve the problems of nutrient loss, indestructible spores, nutrient loss, etc., to extend the shelf life, reduce denaturation rate, improve The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 A kind of preparation method of normal temperature active milk

[0025] This embodiment includes the following steps carried out in sequence:

[0026] S1. Take 80kg of raw milk, filter it, clean the milk, homogenize it at 180bar and 70°C, and pasteurize it at 75°C for 20s to obtain liquid material A;

[0027] S2. After the liquid material A is cooled to 6°C, it is concentrated by RO membrane to obtain concentrated milk B with a fat content of 3.9% and a protein content of 3.3%;

[0028] S3. Steam immersion sterilization of concentrated milk B at 155°C for 0.5s to obtain liquid material C;

[0029] S4. Liquid material C is aseptically homogenized under the condition of 200 bar, and then cooled to 25°C to obtain the normal temperature active milk.

Embodiment 2-6

[0030] The preparation method of embodiment 2-6 normal temperature active milk

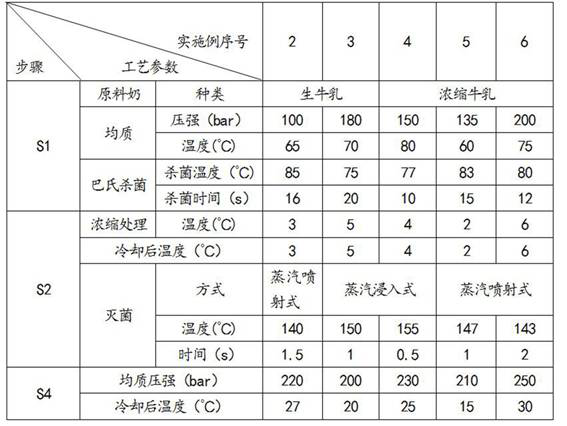

[0031] Examples 2-6 are respectively a method for preparing active milk at normal temperature, and their steps are basically the same as in Example 1, the difference is only in the amount of raw materials and process parameters, see Table 1 for details:

[0032] List of various process parameters in table 1 embodiment 2-6

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com