Compound paracetamol and amantadine hydrochloride capsule filling system and process

A compound paracetamol and filling system technology, which is applied in the field of capsule filling equipment, can solve problems such as affecting capsule sealing, guide shaft wear, and adverse production, and achieve the effects of prolonging service life, improving service life and improving use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

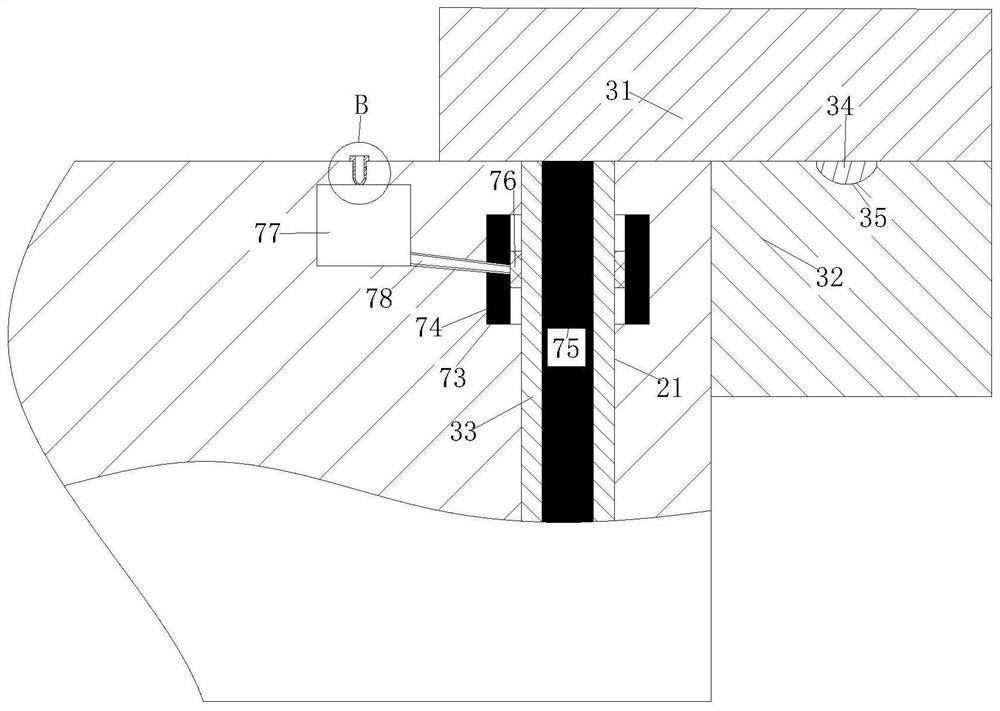

[0060] As an embodiment of the present invention, the connecting mechanism 7 includes a guide block 71 and a guide spring 72; two sets of fixing grooves 73 are arranged on the groove wall of the guide groove 21; two sets of fixing grooves 73 are arranged alternately up and down; each set of fixing grooves 73 The quantity is at least two, and two fixed grooves 73 are arranged symmetrically with respect to guide groove 21; The bottom of fixed groove 73 is connected with guide spring 72; The other end of guide spring 72 is connected with guide block 71; 73 sliding fit, the end of the guide block 71 away from the guide spring 72 fits with the guide shaft 33;

[0061] During work, guide block 71 contacts with guide shaft 33, and guide shaft 33 slides in guide groove 21; The guide block 71 is still in contact with the guide shaft 33, and all the guide blocks 71 support the guide shaft 33 in different directions, so that the guide shaft 33 is still in its original position, so that t...

Embodiment 1

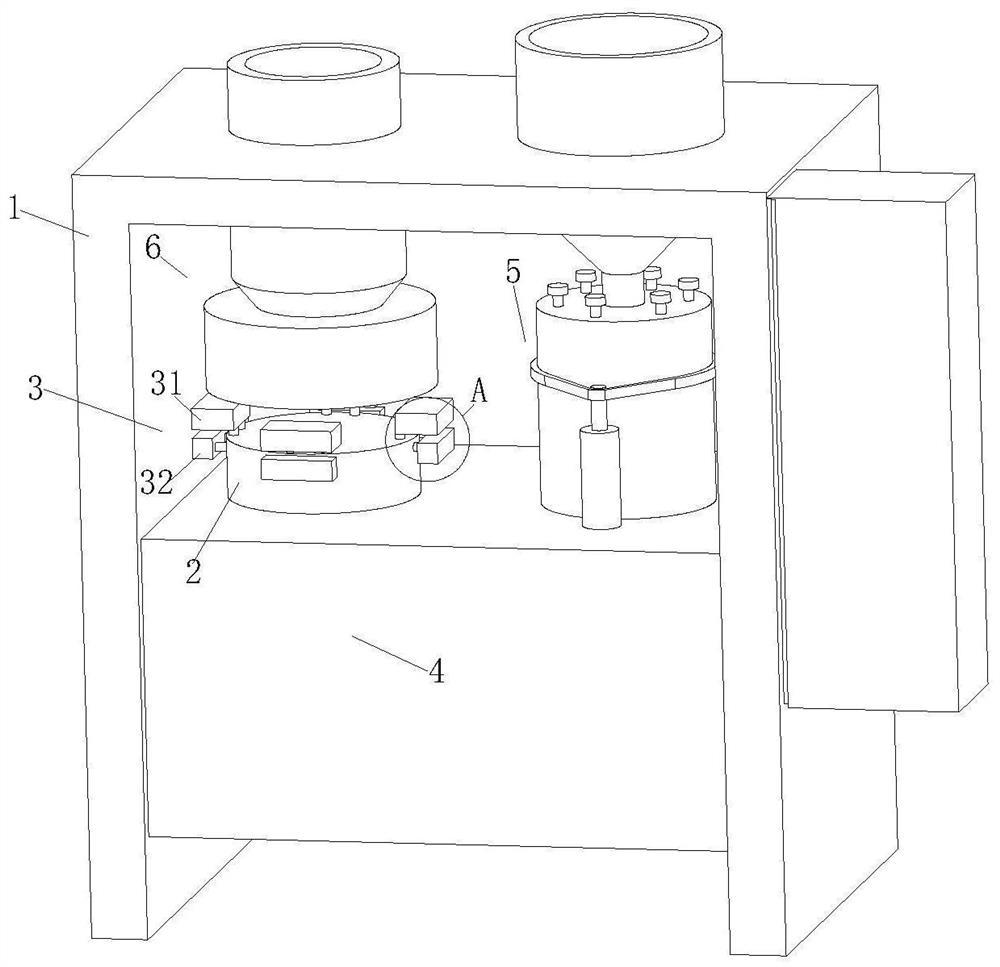

[0084] A compound paracetamol capsule filling system, comprising:

[0085] body 1;

[0086] The turntable 2, located in the body 1, is used to rotate the bag closing mechanism 3, and the turntable 2 is provided with a guide groove 21;

[0087] The driving mechanism 4 is located under the turntable 2 and is used to drive the mechanism in the present invention;

[0088] The feeding mechanism 5, located above the turntable 2, is used to transport empty capsules and medicines;

[0089] The filling mechanism 6 is connected with the feeding mechanism 5 to fill the medicine into the capsule;

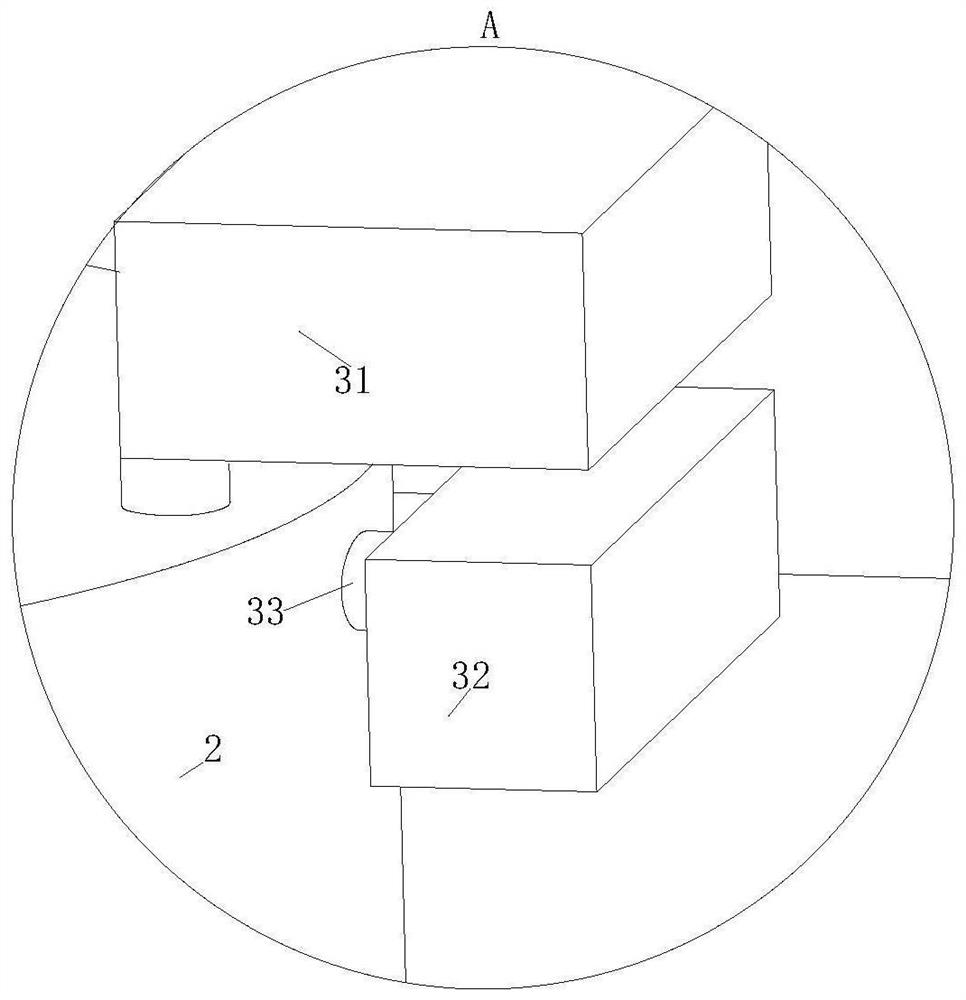

[0090] The capsule closing mechanism 3 includes an upper mold 31 and a lower mold 32, which are used to fasten the capsules filled with medicine up and down; the upper mold 31 and the lower mold 32 are slidably connected to the guide groove 21 through a guide shaft 33;

[0091] a controller to control the automatic operation of the present invention;

[0092] The upper mold 31 and the lower...

Embodiment 2

[0113] Compared with Example 1, the difference is:

[0114] In this embodiment, the connection mechanism 7 includes a fixing slot 73 and an electromagnet 74; the fixing slot 73 is arranged on the slot wall of the guide slot 21, and the number of the fixing slots 73 in the same guide slot 21 is at least two; The grooves 73 are symmetrically arranged with respect to the guide grooves 21, and the fixed grooves 73 are all fixed with the electromagnet 74; the electromagnet 74 does not expose the fixed groove 73; the guide shaft 33 is fixed with a magnet block 75; The magnetic repulsion of the electromagnet 74;

[0115] During operation, the guide shaft 33 slides in the guide groove 21. At this time, the controller controls the electromagnet 74 to be energized, so that the electromagnets 74 on both sides of the guide shaft 33 exert thrust on the magnet blocks 75 in the guide shaft 33, and then the guide shaft 33 is placed in the guide shaft 33. Under the action of the thrust of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com