Rotary locking structure capable of rotating at multiple angles for welding

A locking structure and multi-angle technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inability to adjust multiple angles, difficulty in height adjustment, and insufficient welding processing , to achieve the effect of easy adjustment of angle and height, convenient overall operation, fast splicing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

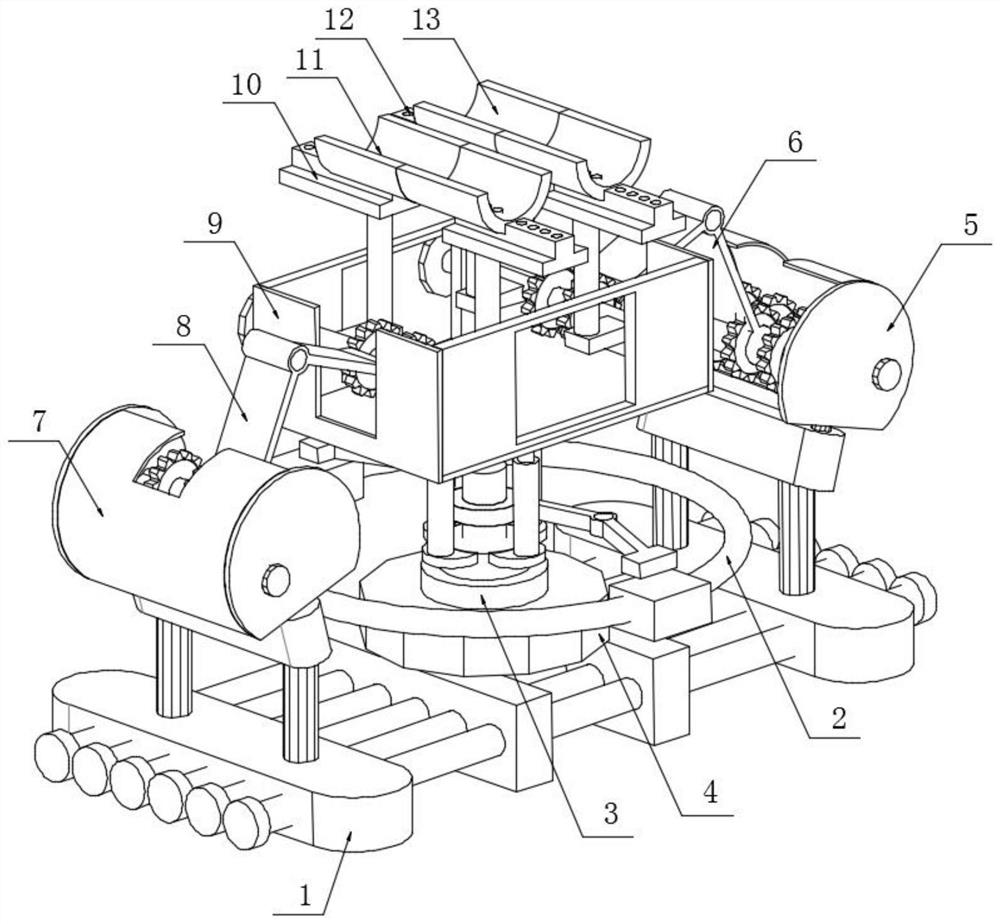

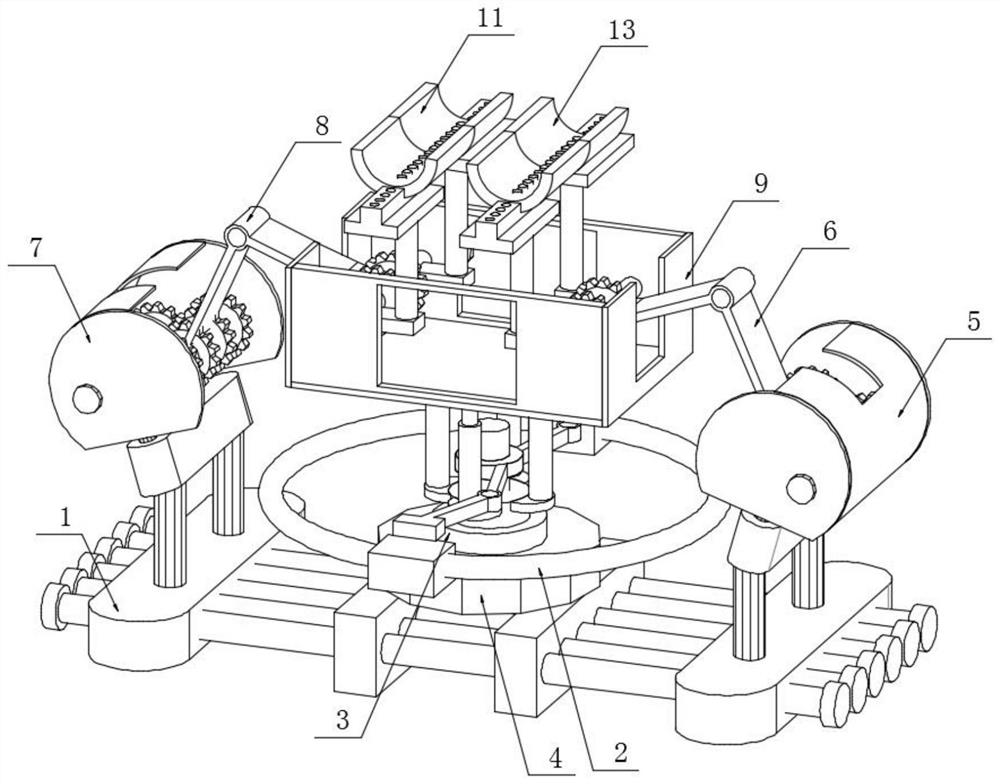

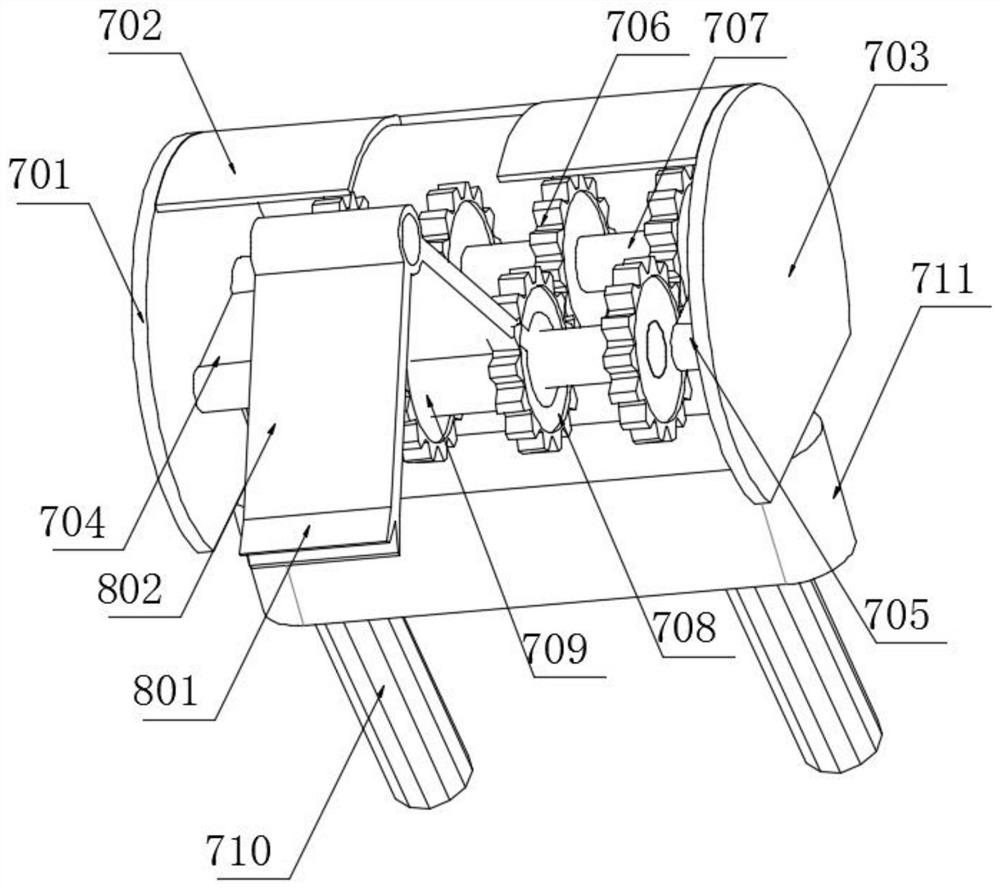

[0030] see Figure 1-8 , in an embodiment of the present invention, a multi-angle rotating welding rotation locking structure, including a support mechanism 1, a primary gear clamp 7 and a circuit control box 4, one end of the top surface of the support mechanism 1 is fixedly connected with a primary gear Clamp 7, the first-stage gear clamp 7 can play the role of clamping, the other end top surface of the support mechanism 1 is fixedly connected with the secondary gear clamp 5, the support mechanism 1 can play the effect of support, convenient Overall support, the inside of the first-stage gear clamp 7 is sleeved with a rotation locking mechanism B8, which can facilitate the overall clamping, and the other end of the rotation locking mechanism B8 is clamped with the lifting storage box 9, and lifting The placement box 9 is used for placing the pipes for lifting. The inside of the secondary gear clamp 5 is sleeved with a rotation locking mechanism A6. The rotation locking mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com