Suspended raw material production equipment for bonding and enhancing performance of carbon fiber fishing rod

A production equipment and carbon fiber technology, which is applied in the field of raw material production equipment for suspension-type bonding to enhance the performance of carbon fiber fishing rods, can solve the problems of stress concentration, affecting the overall performance of fishing rods, and breaking of fishing rods, and achieve the purpose of strengthening the bonding strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

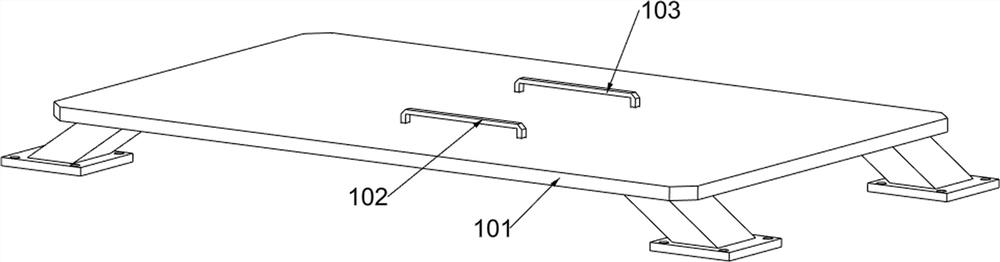

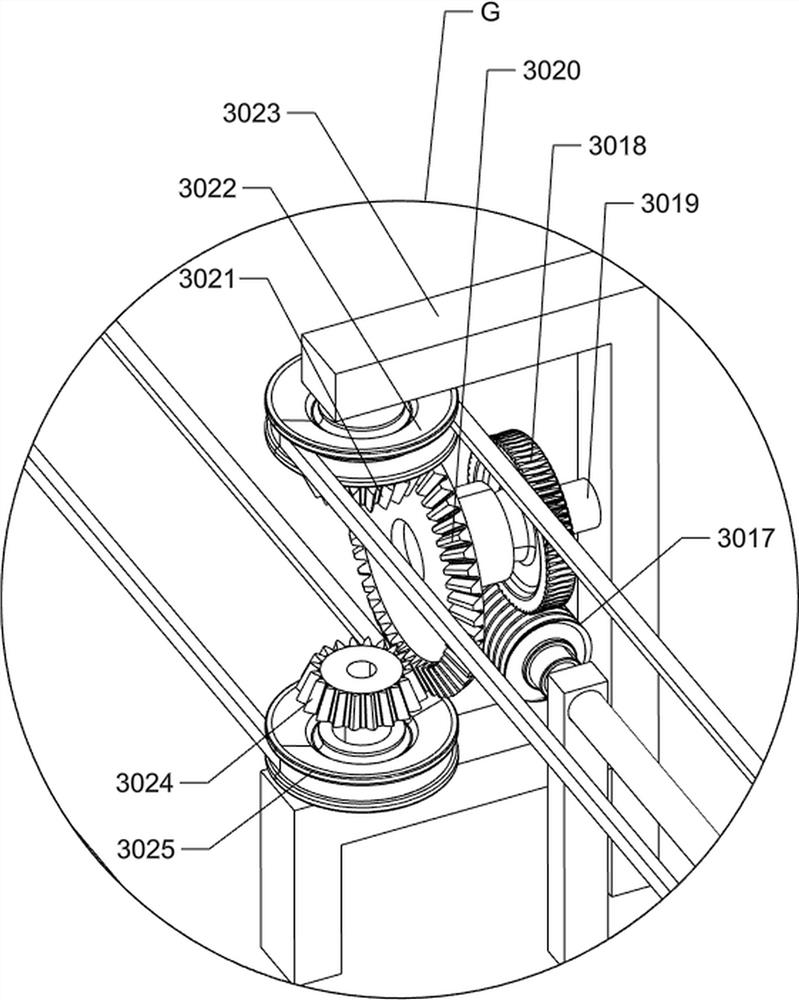

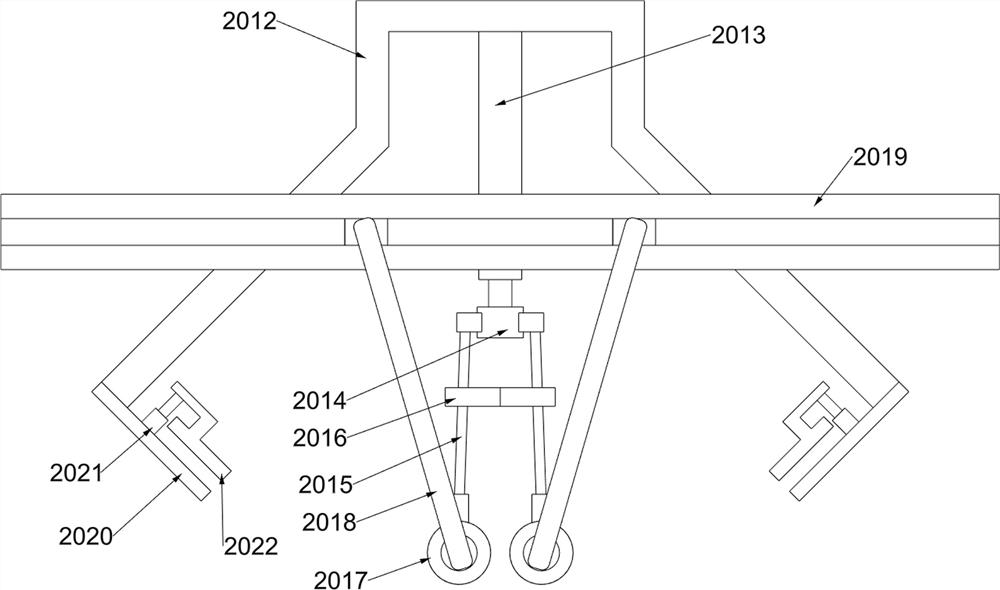

[0034] A kind of raw material production equipment for suspended bonding to enhance the performance of carbon fiber fishing rods, according to Figure 1-3 As shown, it includes a support column 1, a wheel 2, a frame 3, a workbench 4, a protective cover 5, a fitting system and a load-bearing separation system; a group of support columns 1 are respectively provided at the four corners of the lower end surface of the frame 3; 3 The lower end surface is equipped with four sets of wheels 2; the workbench 4 is connected above the frame 3; the protective cover 5 is connected to the rear side above the workbench 4; Fitting system; below the fitting system, there is a load-bearing and detaching system for carrying the graphene elastic cloth and detaching the elastic cloth.

[0035] Before the device is in operation, use the wheels 2 to move the device to a stable working place, then the staff adjusts the height of the four sets of support columns 1 so that the frame 3 is in a horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com