Automatic steel bar vibration guiding device

A technology of guiding devices and steel bars, which is applied to vibrating conveyors, transportation and packaging, and conveyor objects, etc., can solve problems such as low efficiency, time-consuming and labor-intensive, and easy to be stabbed by steel bars, and achieve the effect of improving speed and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

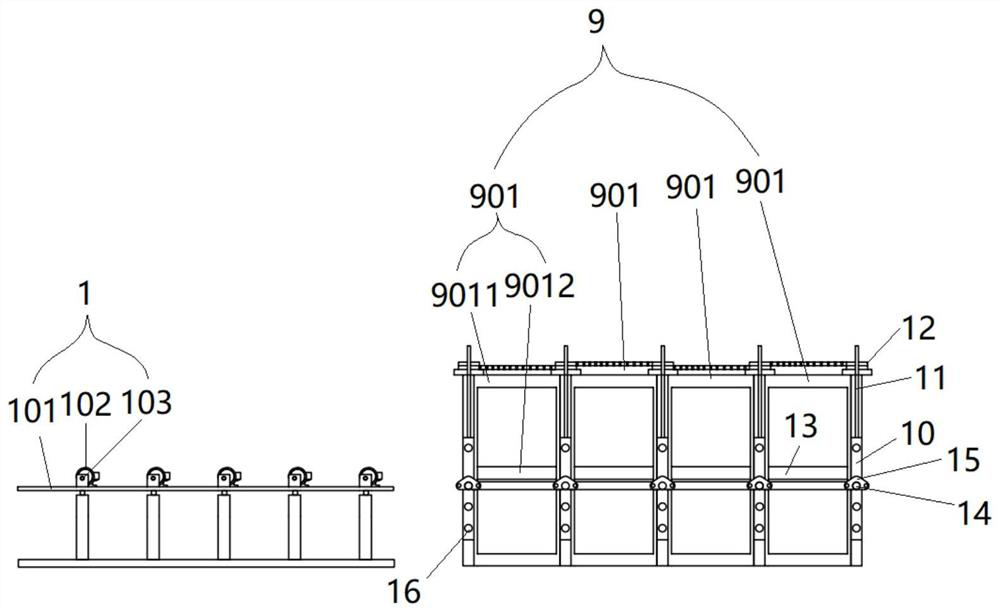

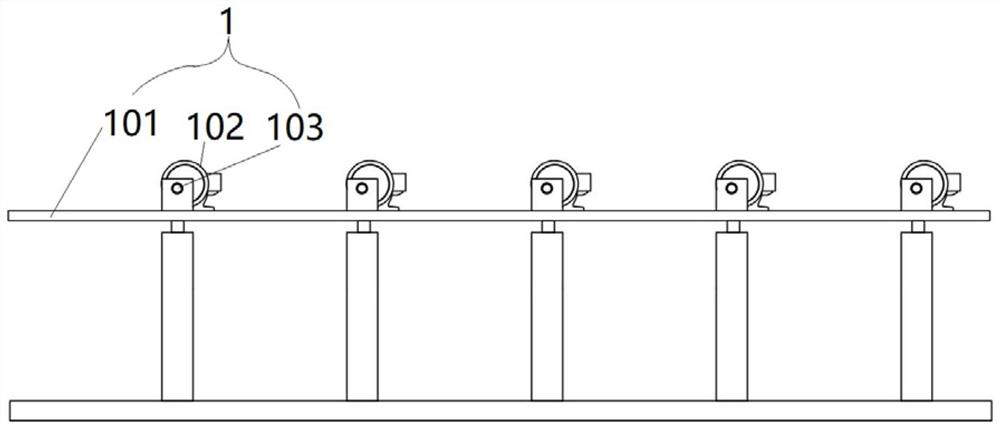

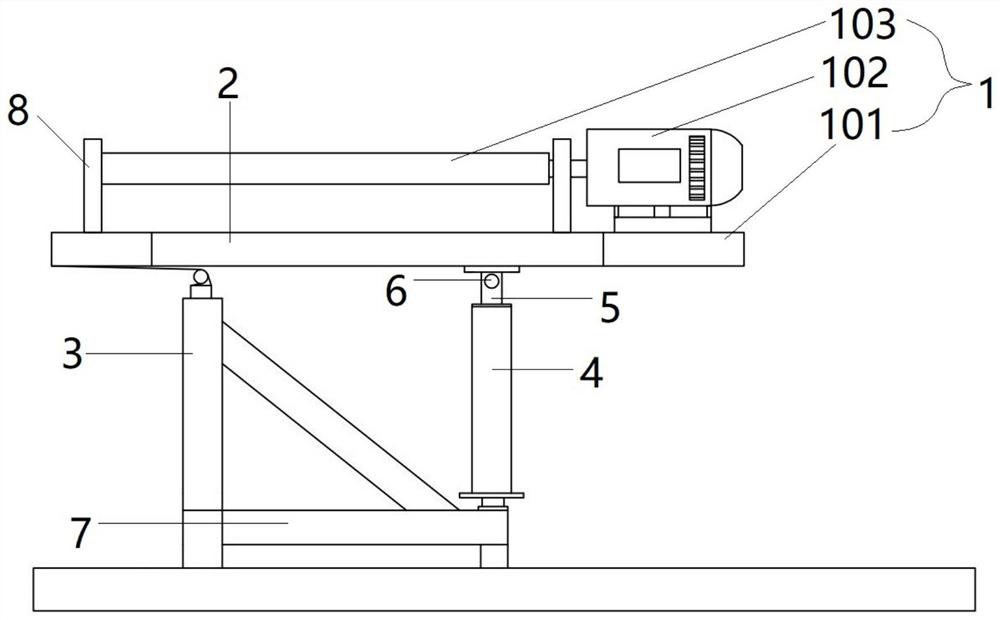

[0029] See attached figure 1 , attached figure 2 And attached image 3 , shows the feeding device 1 in a kind of automatic steel bar vibration guiding device of the present invention, and the feeding device 1 comprises a vibration frame 101, a plurality of eccentric wheel vibrating motors 102 and a plurality of first rotating shafts 103, and the eccentric wheel vibrates Motor 102 is unidirectional rotation, and eccentric wheel vibrating motor 102 is arranged on one side of described vibrating frame 101, and the space between eccentric wheel vibrating motor 102 is evenly arranged, and the first rotating shaft 103 and eccentric wheel vibrating motor 102 are arranged in one-to-one correspondence, One end of the first rotating shaft 103 is connected to the eccentric shaft of the eccentric wheel vibrating motor 102, and the unidirectional rotation of the eccentric random vibrating motor 102 drives the first rotating shaft 103 to rotate in a single direction, thereby ensuring a si...

Embodiment 2

[0032] This embodiment 2 is formed on the basis of embodiment 1, by increasing the storage device 9 to automatically receive and store the steel bars after setting them right, reducing manual labor.

[0033] See attached Figure 4 To attach Figure 6 , shows a storage device 9 in an automatic steel bar vibration guiding device of the present invention, including a storage device 9 for receiving and storing steel bars, and the storage device 9 is arranged on one side of the feeding direction of the feeding device 1 The material storage device 9 includes a plurality of material storage platforms 901, the material storage platform 901 includes a vertical frame 9011 and a material storage plate 9012, and the material storage plate 9012 is arranged in parallel with the first rotating shaft 103, so that the steel bar is fed from the feeding device 1 When it is delivered, it can be received smoothly and reduce bumps.

[0034]The storage tables 901 are arranged side by side horizont...

Embodiment 3

[0036] This embodiment 3 is formed on the basis of embodiment 2, and is a further improvement on the structure of the storage device 9 .

[0037] In the middle of the vertical frame 9011, a third connecting rod 13 is horizontally arranged, and the two ends of the third connecting rod 13 are connected to the vertical frame 9011 by welding. The first rotary gear 12 close to the side of the feeding device 1 is connected with a first drive motor 18 for driving its rotation, and the first rotary gear 12 is driven to move by the first drive motor 18. According to actual needs, The number of storage plates 9012 and the third rotating shaft 14 can be increased, and the third rotating shaft 14 can be inserted into the remaining parallel through holes 16. After fixing the storage plate 9012, an additional storage space can be formed to improve Space utilization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com