Oriented graphene thermally conductive foam, graphene thermally conductive film, preparation method thereof, and electronic product

A technology of oriented alignment and graphene heat conduction film, which is applied in the field of heat conduction materials, can solve the problems of poor longitudinal thermal conductivity and failure to meet the performance requirements of graphene heat conduction film, and achieve the effect of simple operation and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] According to a first aspect of the present invention, there is provided a method for preparing a directional arrangement of graphene thermally conductive foam, comprising the following steps:

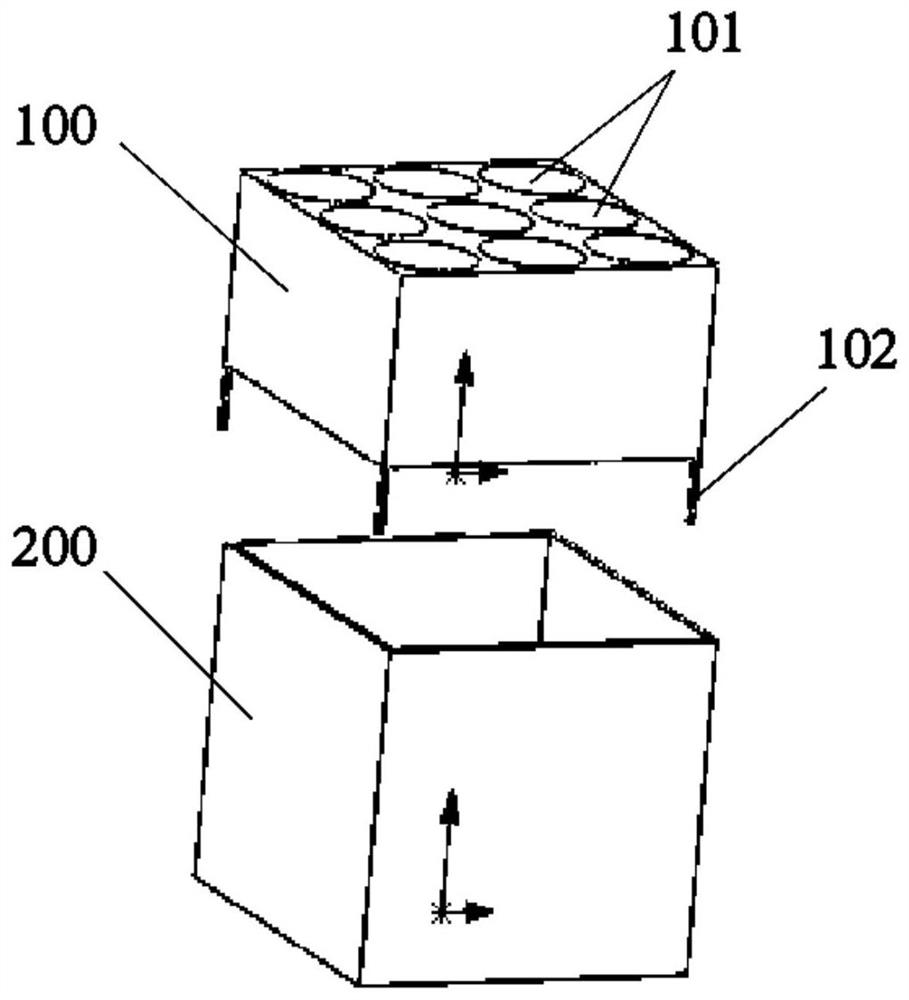

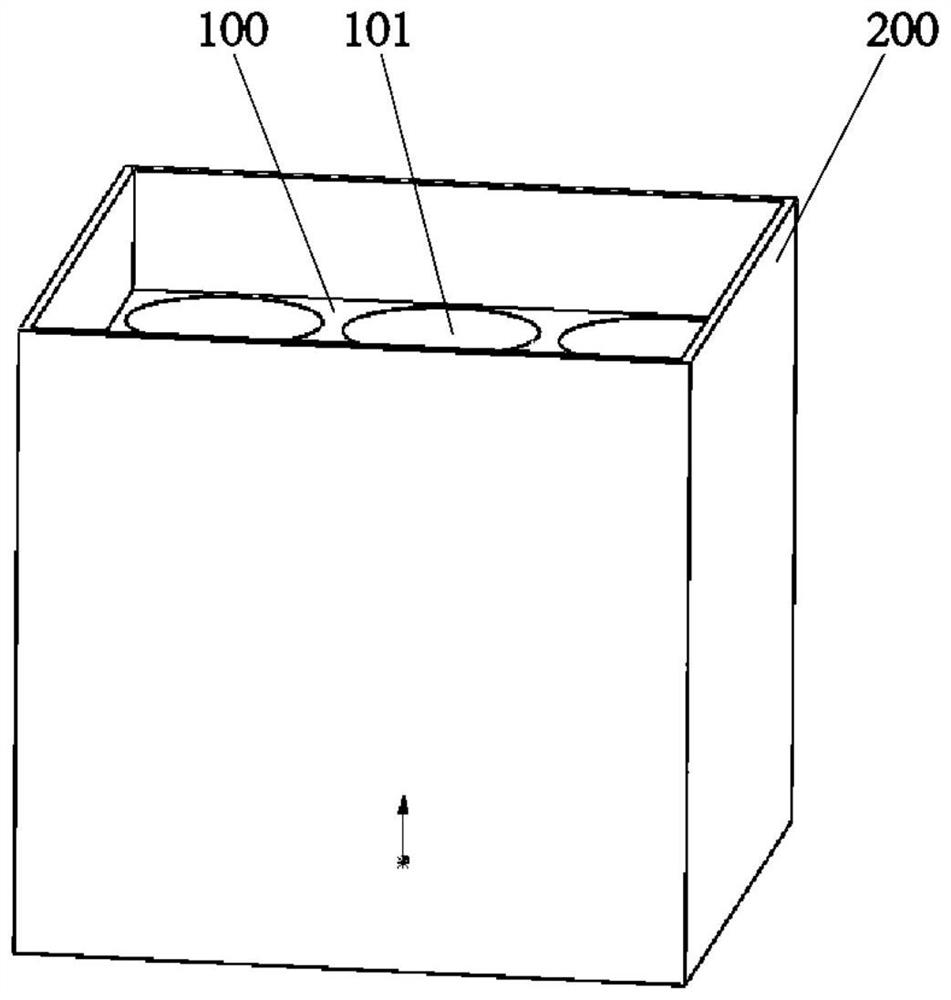

[0058] (a) Partial graphene oxide slurry is injected into a tank containing an array grid, and when the graphene oxide slurry is frozen to the point where there is no fluidity, the array grid is removed from the tank to obtain the first graphene oxide;

[0059] (b) After removal from the array grid, another part of the graphene oxide slurry is injected into the gap and upper surface left by the first graphene oxide, frozen again until the graphene oxide slurry has no fluidity, and then dried to give the graphene oxide;

[0060] (c) The graphene dioxide is carbonized and graphitized and optionally pressed to obtain a directional arrangement of graphene thermally conductive foam.

[0061] Specifically, in step (a), graphene oxide slurry refers to a mixed slurry formed by graphene oxide a...

Embodiment 1

[0109] The present embodiment provides a method for preparing a directional arrangement of graphene thermally conductive foam, comprising the following steps:

[0110] (a) The height of 2 mm, circular miniature through hole diameter of 3 cm array mesh (specific structure such as Figure 1 and Figure 2Shown) placed in a 5mm high tank, the solid content of 5% of the partial graphene oxide slurry directly into the tank, when the graphene oxide slurry height and the array grid height can be at the same time, and then the tank containing graphene oxide slurry is placed in the freezer freezer freezing, freezing temperature is -20 ° C, freezing time is 3h. The graphene oxide slurry can be removed without fluidity, and then the array grid is directly extracted to obtain the first graphene oxide.

[0111] (b) After removal from the array grid, the first graphene oxide slurry is injected with another part of the graphene oxide slurry with a solid content of 5% and the upper surface of the ...

Embodiment 2

[0114] The present embodiment provides a method for preparing a directional arrangement of graphene thermally conductive foam, comprising the following steps:

[0115] (a) The height of 50mm, circular micro through hole diameter of 3cm array grid placed in a 100mm height of the tank, the solid content of 5% of the part of the graphene oxide slurry directly into the tank, when the height of graphene oxide slurry and the height of the array grid can be, and then the tank containing graphene oxide slurry is placed in the freezer freezer, freezing temperature is -20 °C, freezing time is 3h. The graphene oxide slurry can be removed without fluidity, and then the array grid is directly extracted to obtain the first graphene oxide.

[0116] (b) After removal from the array grid, the first graphene oxide slurry is injected with another part of the graphene oxide slurry with a solid content of 5% and the upper surface of the solid content of 5% until it is the same as the height of the tan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com