Method for calculating blast furnace burden distribution drop point based on laser measurement data

A laser measurement and data calculation technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve the problems of long lag of distribution to furnace conditions, confusing blast furnace operators to accurately grasp, etc., to achieve good accuracy, reduce energy consumption, improve The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

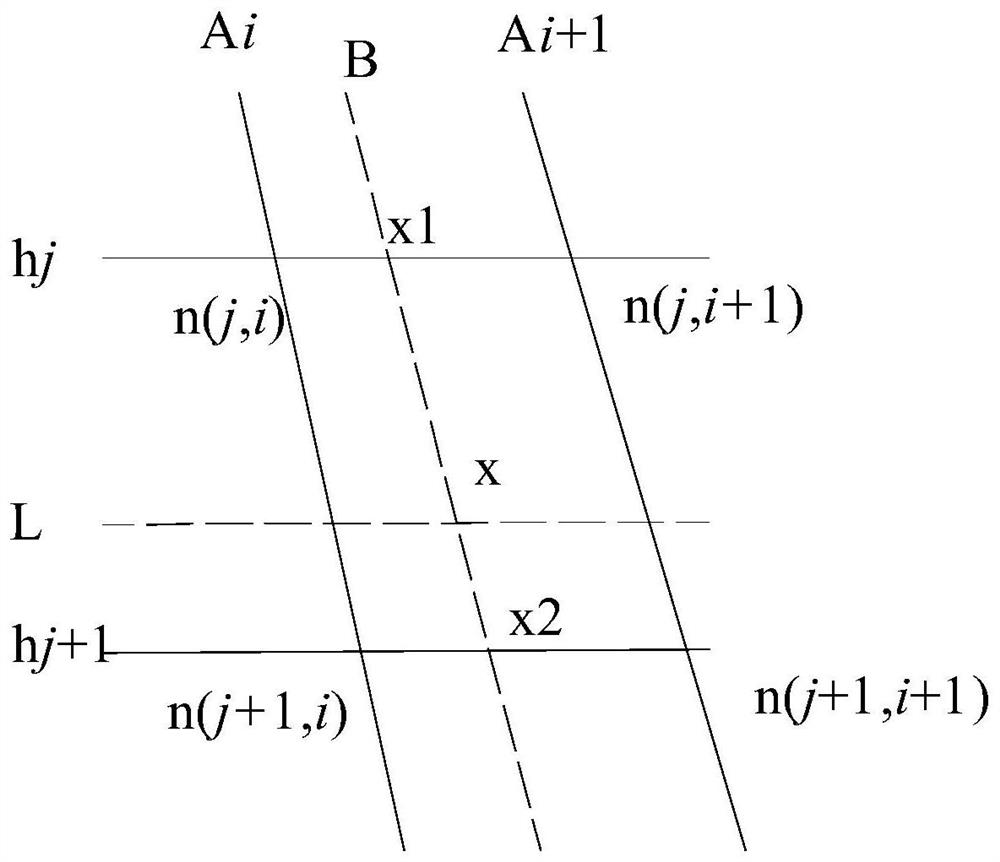

[0026] Embodiment 1: see figure 1 , a method for calculating a blast furnace cloth drop point based on laser measurement data, said method comprising the following steps: Step 1: calibration of basic data;

[0027] Step 2: Division of calculation scope;

[0028] Step 3: Calculation of any angle under the basic material line;

[0029] Step 4: Calculate the inclination angle of any chute under any material line.

[0030] Step 1: Calibration of the basic data, as follows,

[0031] While the blast furnace is charging, use the manhole on the top of the furnace and use the space grid device to form a spatial coordinate system in the furnace, and use the laser measurement method to continuously capture the images of the material flow trajectory of the ore and coke at 5 to 20 angles , process the ingested images by computer to obtain the drop point data at the next 5-15 fixed material lines at the base angle, organize the data as shown in Table 3, and then complete the calibration;...

specific Embodiment 1

[0042] Specific embodiment 1: a method for calculating the falling point of blast furnace cloth based on laser measurement data, the method includes the following steps: Step 1: calibration of basic data;

[0043] Step 2: Division of calculation scope;

[0044] Step 3: Calculation of any angle under the basic material line;

[0045] Step 4: Calculate the inclination angle of any chute under any material line, as follows:

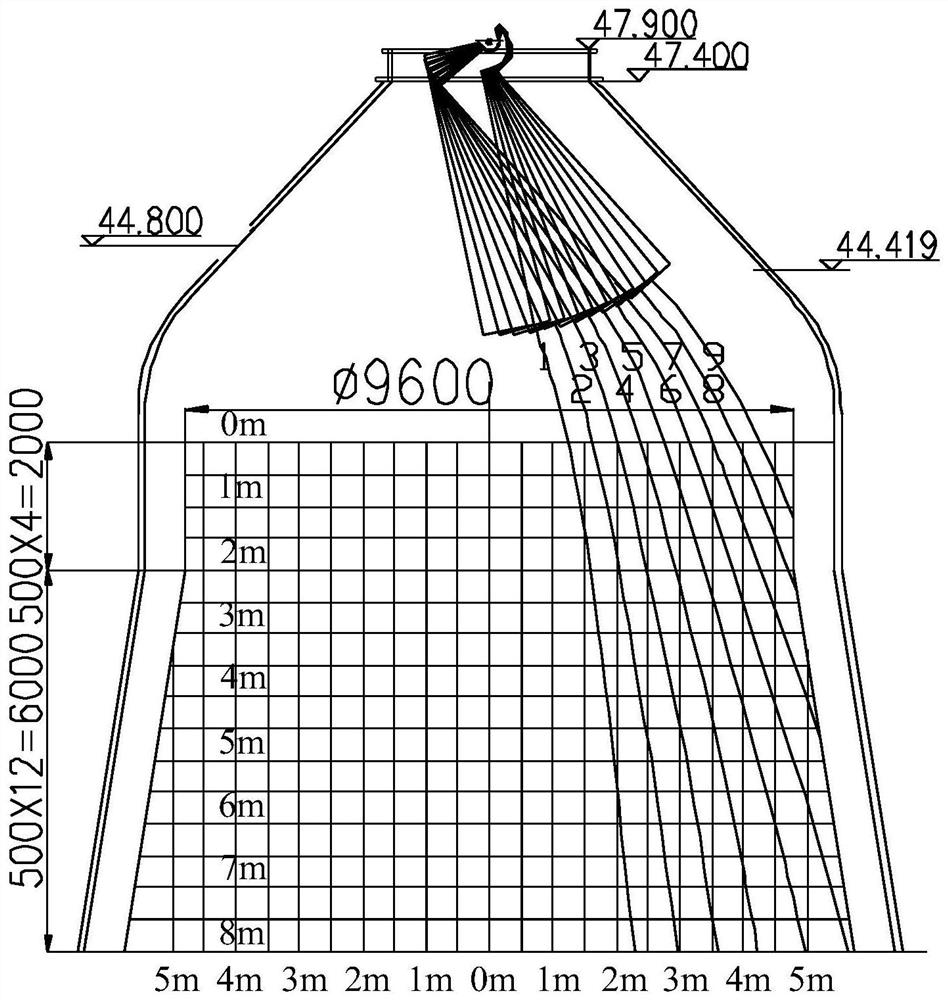

[0046] 1. Taking a blast furnace as an example, calculate the ore distribution point when the inclination angle of the chute is 37° and the material line is 1.3m.

[0047] 2. When the blast furnace was started, the material flow trajectory of the ore under the basic chute inclination angle and the basic material line was measured. The measurement results are shown in the attached figure 2 , the corresponding drop point position is attached figure 2 The intersection of the material flow trajectory of the inclination angle of the middle base chute and the...

specific Embodiment 2

[0058] Specific embodiment 2: a method for calculating the blast furnace cloth drop point based on laser measurement data, the method includes the following steps: Step 1: calibration of basic data;

[0059] Step 2: Division of calculation scope;

[0060] Step 3: Calculation of any angle under the basic material line;

[0061] Step 4: Calculate the inclination angle of any chute under any material line, as follows:

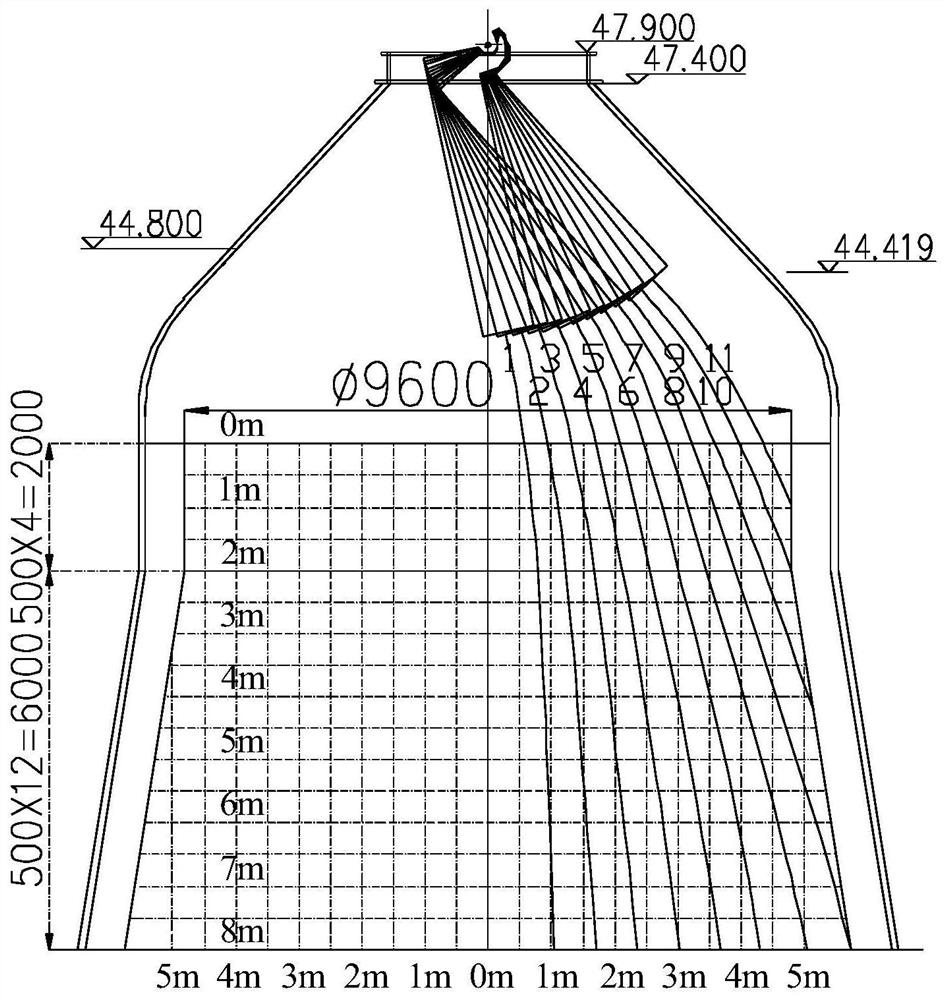

[0062] 1. Taking a blast furnace as an example, calculate the coke distribution point when the inclination angle of the chute is 34.5° and the material line is 1.2m;

[0063] 2. When the blast furnace was opened, coke was measured at the inclination angle of the base chute and the material flow trajectory under the base material line. The measurement results are shown in the attached image 3 , the corresponding drop point position is attached image 3 The intersection of the material flow trajectory of the inclination angle of the medium base chute and the dot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com