Composite textured surface for radial sliding bearing

A radial sliding, composite weaving technology, applied in the direction of bearing components, shafts and bearings, rolling resistance optimization, etc., can solve the problem that texture can not achieve friction and wear performance, achieve significant hydrodynamic pressure effect, and improve tribological properties , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

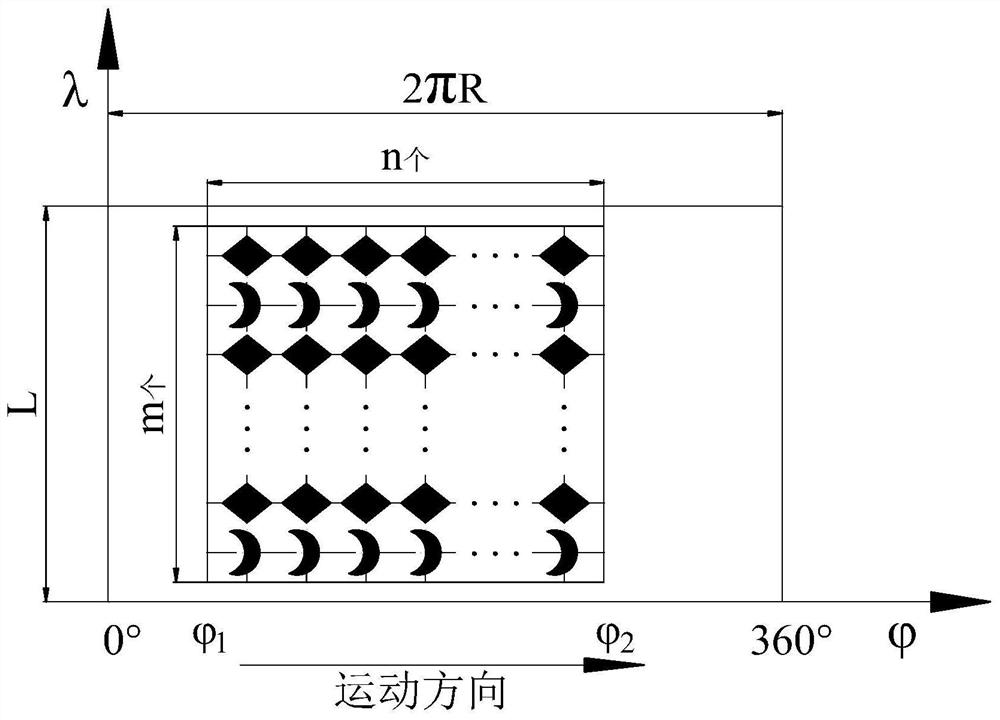

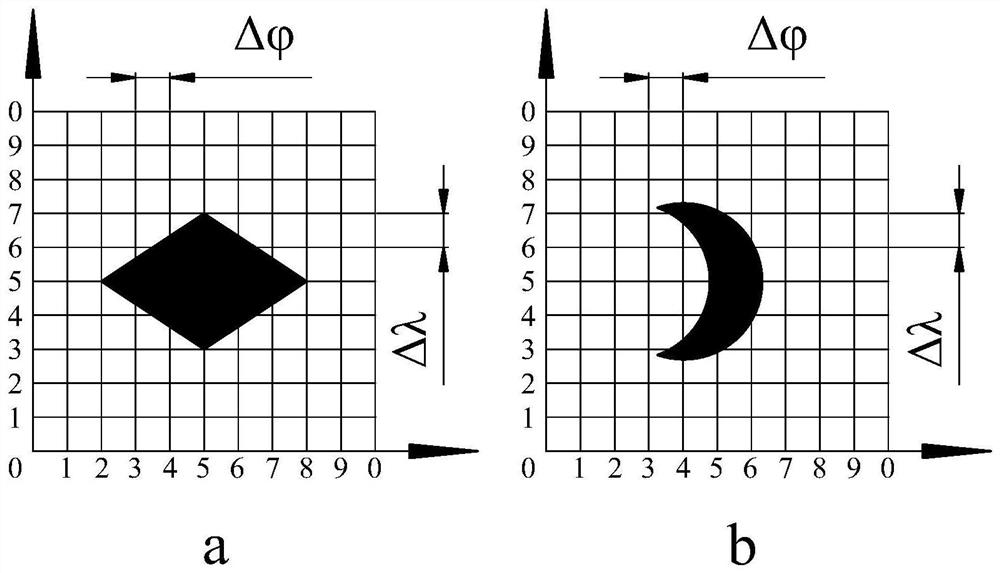

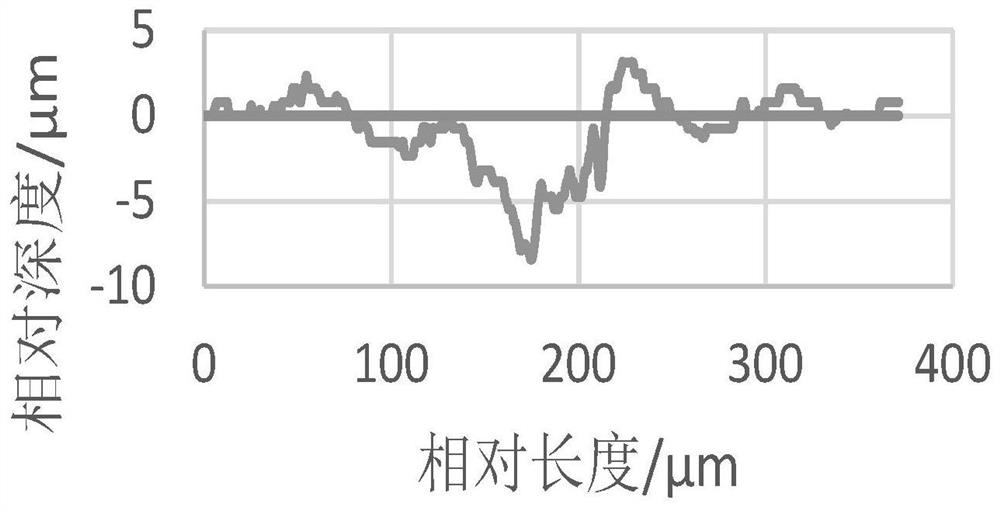

[0023] like figure 1 As shown in , a composite textured surface for radial sliding bearings is set on the inner surface of the bearing bush. The composite texture is distributed at the entrance of the radial sliding bearing, starting from the thickest oil film position to start setting the texture array, to position terminates, the texture array is a rectangular matrix, to The set length between them accounts for one-third of the circumferential length of the bearing (2πR); the area density of the composite texture is 10%, and it consists of two textures with different shapes, the two shapes are rhombus and crescent, The rhomboid texture and the crescent texture are alternately arranged in the axial direction (λ), and in the circumferential direction Each row of textures above has the same shape and is arranged parallel to the moving direction of the radial sliding bearing. combine figure 2 The shape design drawing of the middle texture, the length ratio between the...

Embodiment 2

[0028] A composite textured surface for radial sliding bearings, which is arranged alternately with diamond-shaped and crescent-shaped textures, and its setting position, array arrangement, and shape and size are the same as those described in Example 1, changing the diamond-shaped texture and the setting depth of the crescent-shaped texture are both 12 μm. At this time, the bearing capacity of the diamond-shaped and crescent-shaped composite textured bearings is 4.5097N, and the friction coefficient is 0.3146, which is 1.15% higher than that of the smooth bearing, and the friction coefficient is reduced by 1.44%.

Embodiment 3

[0030] A composite textured surface for radial sliding bearings, which is set on the inner surface of the bearing bush, the composite texture is distributed at the inlet of the radial sliding bearing, starting from the thickest oil film position to start setting the texture array, to position terminates, the texture array is a rectangular matrix, to The set length between them accounts for one-third of the circumferential length of the bearing (2πR); the area density of the composite texture is 10%, and it is composed of two textures with different shapes, the two shapes are rhombus and leaf shape, The rhomboid texture and the leaf-shaped texture are alternately arranged in the axial direction (λ), and in the circumferential direction Each row of textures above has the same shape and is arranged parallel to the moving direction of the radial sliding bearing. The length ratio between the major axis and the minor axis in the rhombus texture is 3:2, and when it is arrange...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com