A composite coating material for improving the tribological properties of tc4 alloy and its preparation method

A composite coating and tribology technology, applied in the direction of metal material coating process, coating, metal processing equipment, etc., can solve the problems of low bonding strength, harmful environment, slow physical vapor deposition speed, etc. Effects of improved performance, improved surface wear resistance, and improved average hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1 of the present invention is: a composite coating material for improving the tribological properties of TC4 alloy and a preparation method thereof.

[0051] The composite coating material is composed of the following raw materials by weight fraction: 5wt.%Ti 3 SiC 2 , 10wt.% Cu and the balance is Co.

[0052] The preparation method of above-mentioned composite coating material, comprises the following steps:

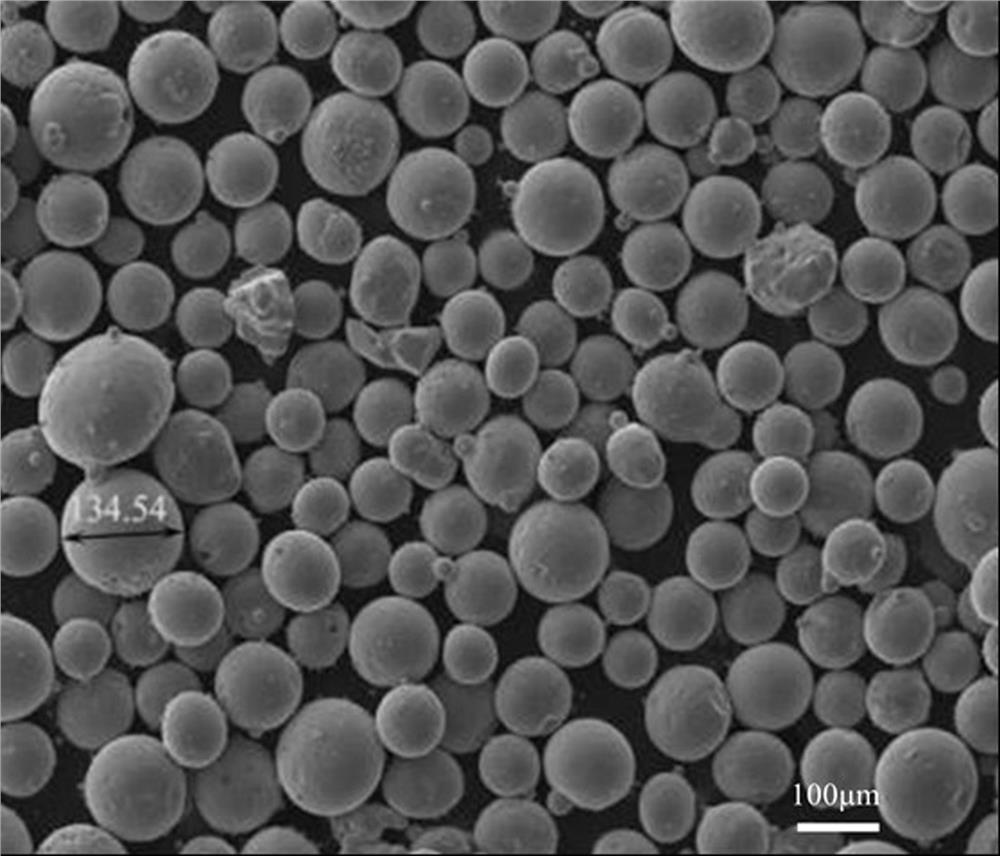

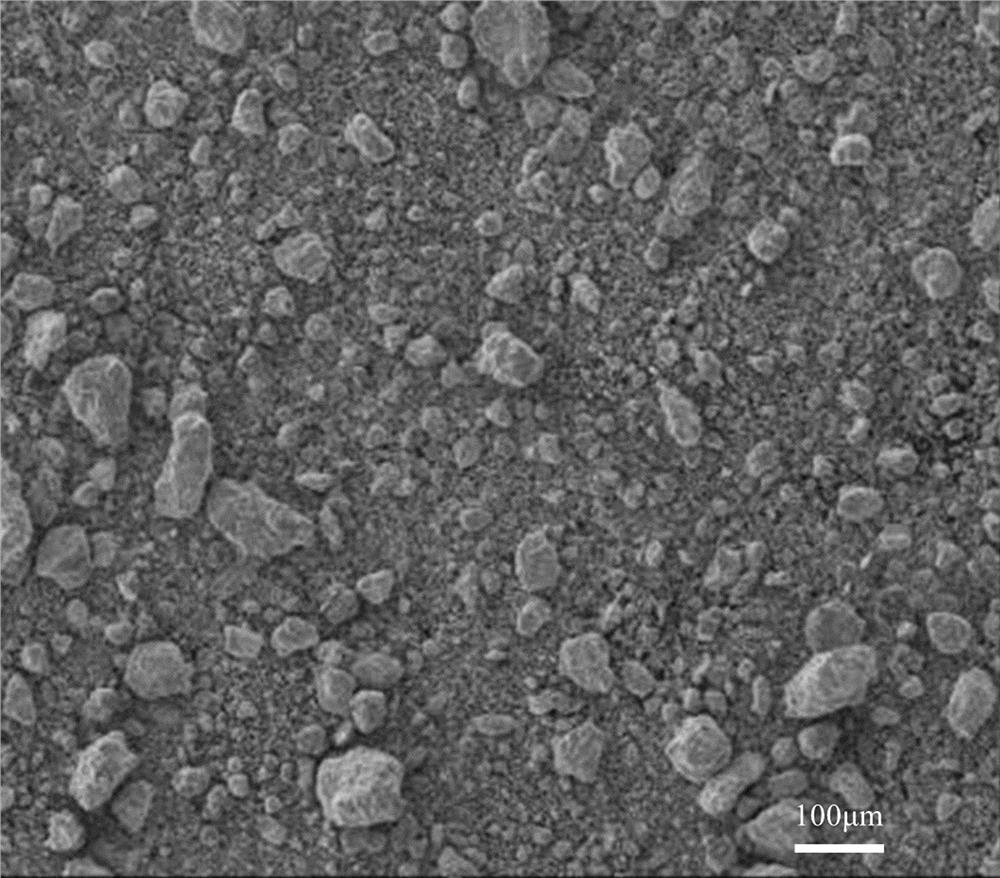

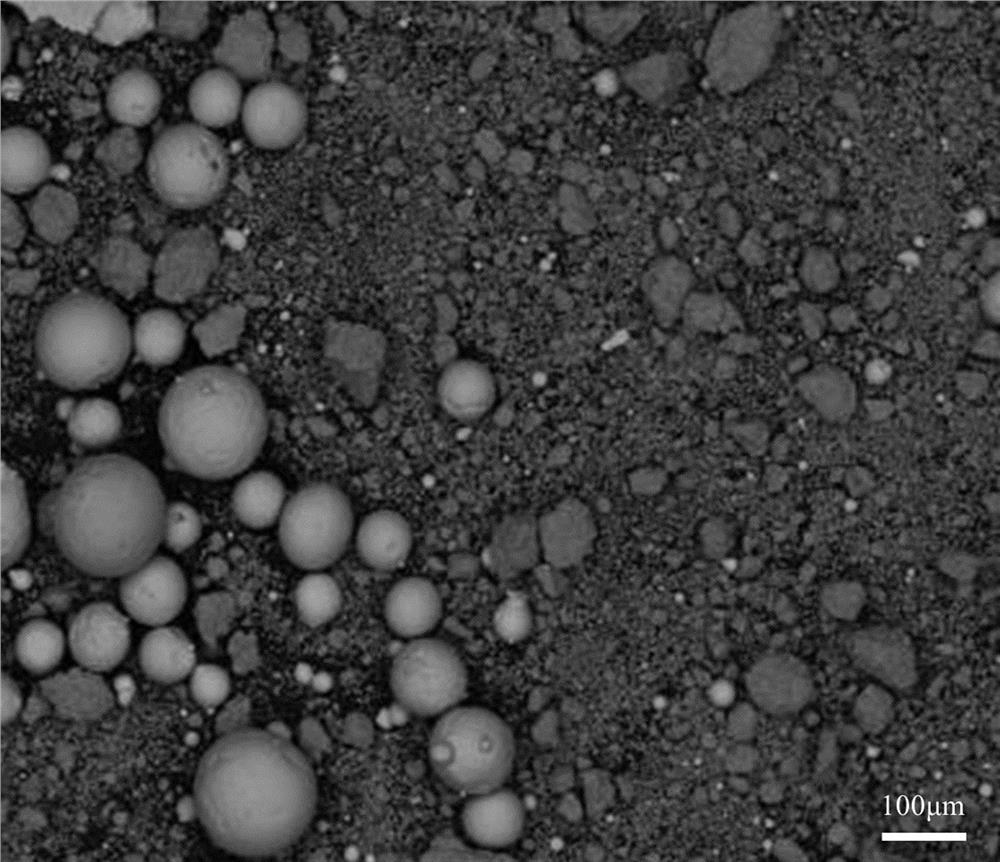

[0053] S1. Put the above raw materials into a DECO-PBM-V-0.4L vertical planetary ball mill and ball mill for 2 hours to obtain an alloy powder mixture, and dry it in a vacuum oven at 100°C for 2 hours;

[0054] S2, using 400 mesh, 600 mesh, 800 mesh, 1200 mesh and 2000 mesh sandpaper in turn to polish the TC4 alloy substrate;

[0055] S3. Use the LDM-8060 powder feeding laser to scan the surface of the TC4 alloy substrate by synchronous powder feeding method, and form a composite coating material on the surface of the TC4 alloy substrate; where the ...

Embodiment 2

[0058] Embodiment 2 of the present invention is: a composite coating material for improving the tribological properties of TC4 alloy and a preparation method thereof.

[0059] Its difference with Embodiment 1 is:

[0060] The composite coating material is composed of the following raw materials by weight fraction: 20wt.% Cu, 5wt.%Ti 3 SiC 2 and the balance is Co.

Embodiment 3

[0061] Embodiment 3 of the present invention is: a composite coating material for improving the tribological properties of TC4 alloy and a preparation method thereof.

[0062] Its difference with Embodiment 1 is:

[0063] Step S3: Use the LDM-8060 powder-feeding laser to scan the surface of the TC4 alloy substrate by synchronous powder-feeding method, and form a composite coating material on the surface of the TC4 alloy substrate; wherein, the output power is 1.6 kW, and the spot diameter is 2.5 mm , the scanning speed is 13 mm / s, the powder feeding rate is 12g / min, the defocus is -1mm, the overlap rate is 50%, and the energy density is 49.23 J / mm 2 .

[0064] Embodiment 4 of the present invention is: a composite coating material for improving the tribological properties of TC4 alloy and a preparation method thereof.

[0065] Its difference with Embodiment 1 is:

[0066] Step S3: Use the LDM-8060 powder-feeding laser to scan the surface of the TC4 alloy substrate by synchro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com