Drying device for textile production

A drying device and textile technology, applied in the direction of textiles and papermaking, drying, dryers, etc., can solve the problems of not meeting the use requirements, deformation and wrinkles, affecting processing, etc., to facilitate subsequent processing, good heat setting, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

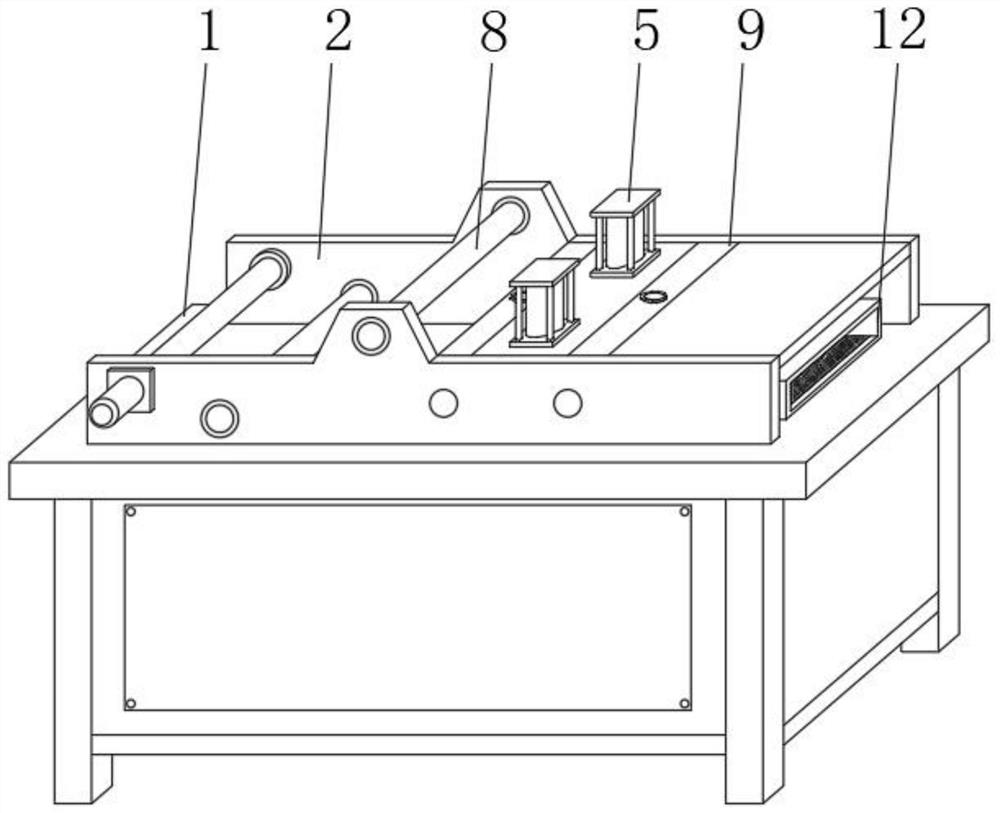

[0031] A drying device for textile production, such as Figure 1-5 As shown, including the device main body 1, two sets of vertical plates 2 are arranged on the upper end surface of the device main body 1, and a guiding device, a preheating device and a drying assembly are arranged between the vertical plates 2, and the preheating device is located between the guiding device and the drying assembly. between components;

[0032] The preheating device includes a mounting plate, an adjustment component, a drying seat 3 and a drying plate 4. The front end and the rear end of the mounting plate are respectively connected with two sets of vertical plates 2, and the adjusting component is installed on the upper surface of the mounting plate. The drying seat 3 and the drying plate 4 are all located directly below the mounting plate, the adjustment assembly is connected with the drying plate 4, and the drying seat 3 is installed on the telescopic rod on the upper end surface of the dev...

Embodiment 2

[0042] A drying device for textile production, such as Figure 1-5 Shown, compared with the first embodiment of the first embodiment, the following structure is also described:

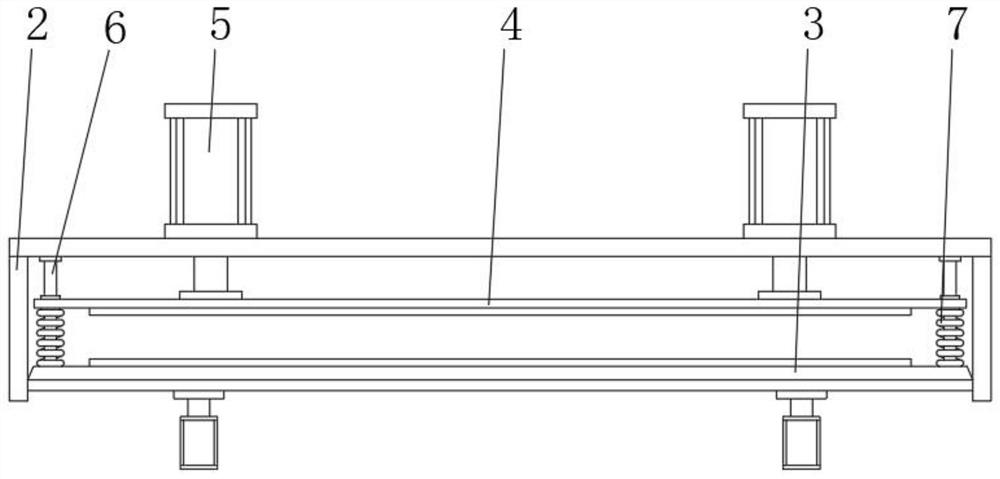

[0043] The adjustment assembly includes two sets of lifting columns 5, the lifting columns 5 are installed on the upper surface of the mounting plate, and the ends of the telescopic ends of the lifting columns 5 pass through the mounting plate and are fixedly connected with the upper surface of the drying plate 4.

[0044] The lifting column 5 can change the height of the drying seat 3, and the telescopic rod can change the height of the drying seat 3, and the lifting column 5 and the telescopic rod can be electric or pneumatic.

[0045] Both the front end and the rear end of the upper end surface of the drying seat 3 are fixedly equipped with guide columns 6 , the upper ends of the guide columns 6 are fixedly connected with the lower end surface of the mounting plate, and the guide columns 6 penetrat...

Embodiment 3

[0050] A drying device for textile production, such as Figure 1-5 As shown, compared with Example 2, this embodiment also records the following structure:

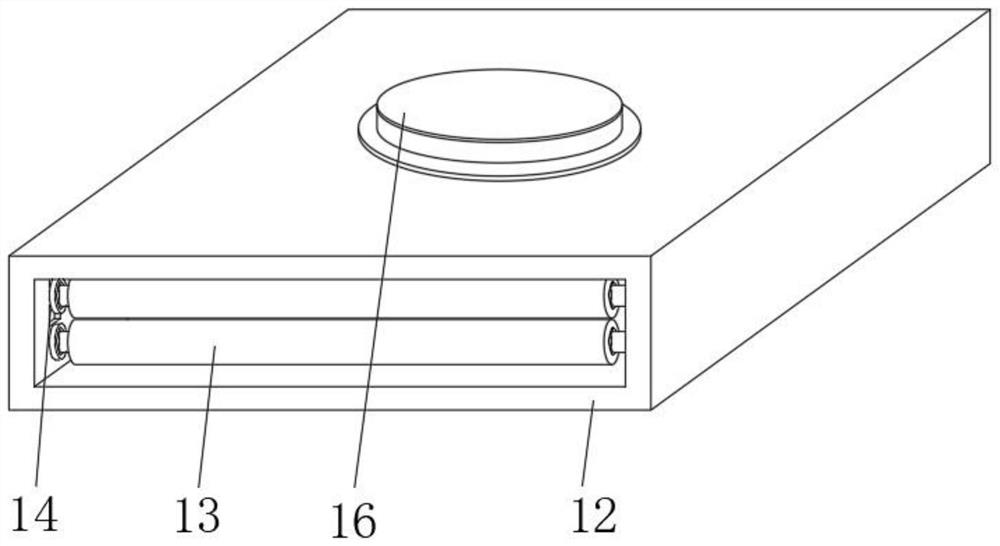

[0051] The drying assembly includes a drying box 12 , openings are opened at both ends of the drying box 12 , and the outer surface of the lower end of the drying box 12 is fixedly installed on the upper surface of the device main body 1 .

[0052] The inside of the drying box 12 is provided with several groups of drying parts at equal intervals, and the drying parts include two groups of heating rollers 13. The front end of the inner surface of the drying box 12 and the rear end of the inner surface of the drying box 12 are provided with several groups of sliding parts at equal intervals, wherein One group of heating rollers 13 is fixedly installed on the inner surface of the drying box 12, and another group of heating rollers 13 is installed on the sliding member.

[0053] One group of heating rollers 13 in the drying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com