Multifunctional composite current collector and preparation method thereof

A current collector and multi-functional technology, applied in the field of lithium-ion batteries, can solve the problems of limited improvement of battery safety, deterioration of battery rate performance, and impact on the conductivity of current collectors, so as to achieve timely electron transmission and isolate electron transmission , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

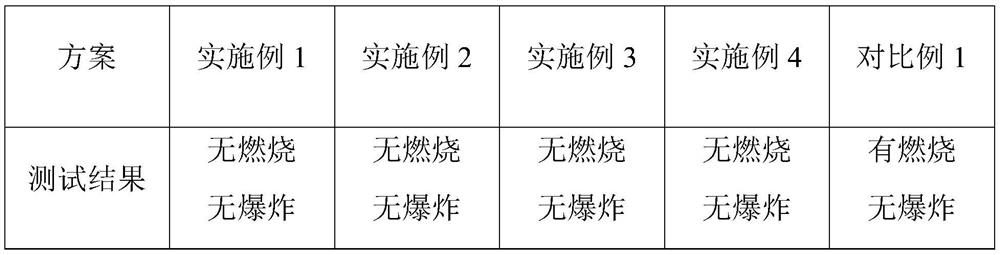

Examples

Embodiment 1

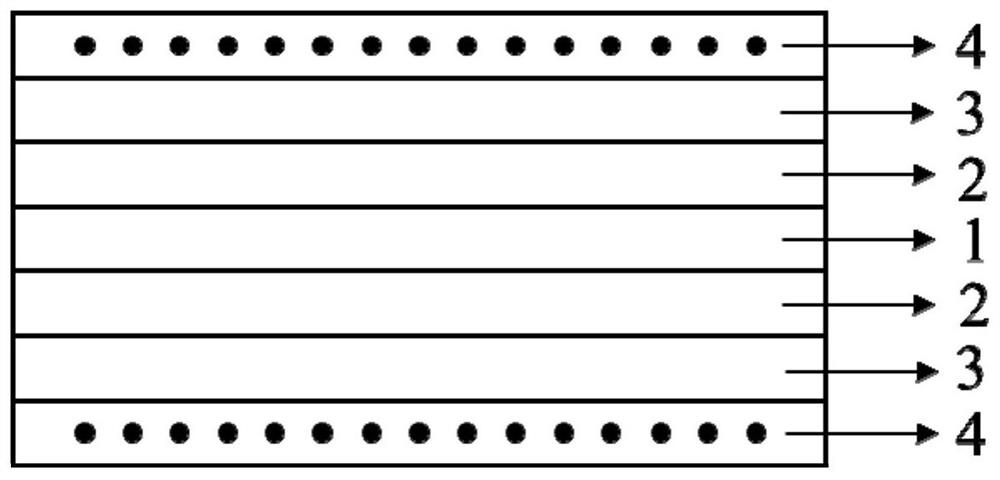

[0026] The preparation method of the novel multifunctional current collector and lithium-ion battery provided in Embodiment 1 of the present invention comprises the following steps:

[0027] (1) Firstly, plasma cleaning is performed on the surface of the commercialized PET polymer film to remove impurities on the surface.

[0028] (2) An alumina bonding layer with a thickness of 50 nm was prepared on the upper and lower surfaces of the cleaned film by vapor deposition.

[0029] (3) Place the thin film evaporated with the adhesive enhancing layer on the evaporated film substrate to prepare a metal aluminum layer with a thickness of about 800 nm.

[0030] (4) A temperature responsive layer with a thickness of 500 nm was prepared on the surface of the current collector on which the metal layer was evaporated. Among them, the response layer is composed of 10% conductive carbon black and 90% low-density polyethylene. The desired multifunctional composite current collector can be ...

Embodiment 2

[0033] The preparation method of the novel multifunctional current collector provided in Example 2 of the present invention comprises the following steps:

[0034] (1) Firstly, plasma cleaning is performed on the surface of the commercialized PET polymer film to remove impurities on the surface.

[0035] (2) An alumina bonding layer with a thickness of 50 nm was prepared on the upper and lower surfaces of the cleaned film by vapor deposition.

[0036] (3) Place the thin film evaporated with the adhesive enhancing layer on the evaporated film substrate to prepare a metal aluminum layer with a thickness of about 800 nm.

[0037] (4) A temperature responsive layer with a thickness of 500 nm was prepared on the surface of the current collector on which the metal layer was evaporated. Among them, the response layer is composed of 20% conductive carbon black and 80% low-density polyethylene. The desired multifunctional composite current collector can be obtained.

[0038] (5) The...

Embodiment 3

[0040] The preparation method of the novel multifunctional current collector provided in Example 3 of the present invention comprises the following steps:

[0041] (1) Firstly, plasma cleaning is performed on the surface of the commercialized PET polymer film to remove impurities on the surface.

[0042] (2) An alumina bonding layer with a thickness of 50 nm was prepared on the upper and lower surfaces of the cleaned film by vapor deposition.

[0043] (3) Place the thin film evaporated with the adhesive enhancing layer on the evaporated film substrate to prepare a metal aluminum layer with a thickness of about 800 nm.

[0044] (4) A temperature responsive layer with a thickness of 500 nm was prepared on the surface of the current collector on which the metal layer was evaporated. Among them, the response layer is composed of 30% conductive carbon black and 70% low-density polyethylene. The desired multifunctional composite current collector can be obtained.

[0045] (5) The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com