Production equipment and preparation method of crispy sesame jujube

A production equipment and technology for sesame jujube, which is applied to the production equipment and preparation field of crispy sesame jujube, can solve the problems of uneven wrapping and insufficient crispness of red dates, and achieve the effects of even wrapping, ensuring crisp taste, and avoiding burning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

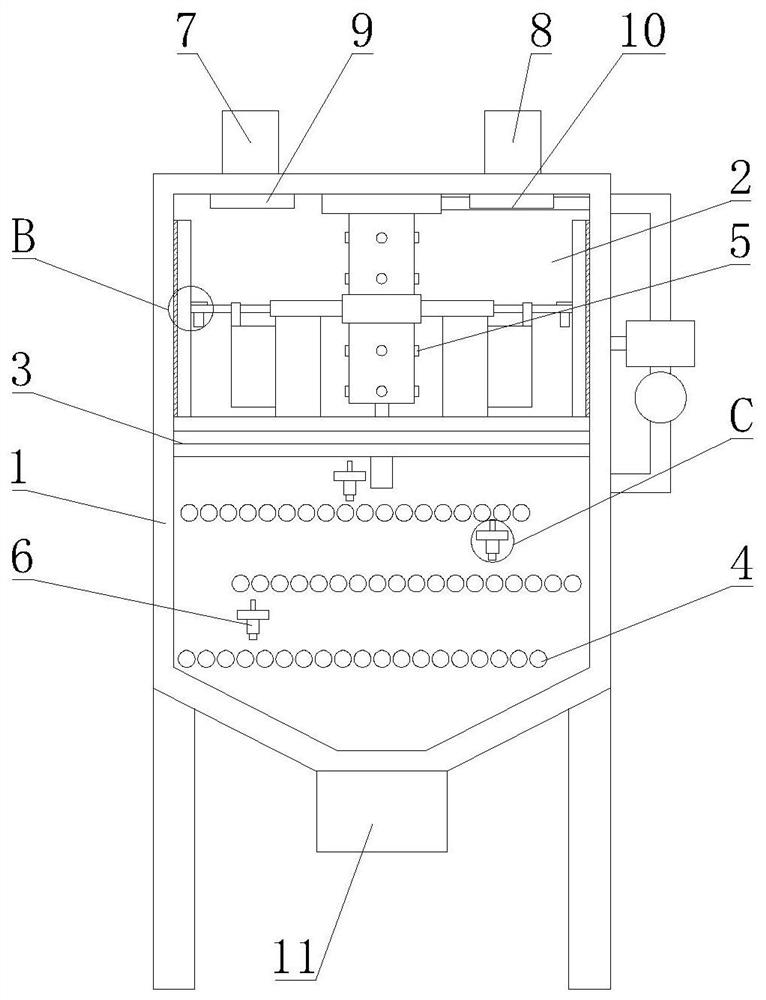

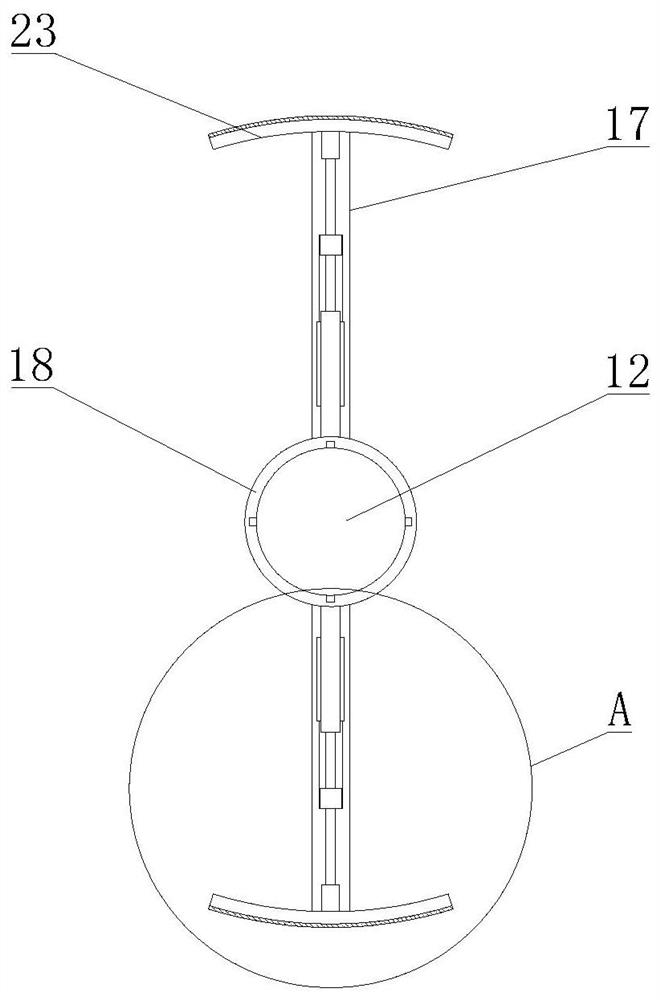

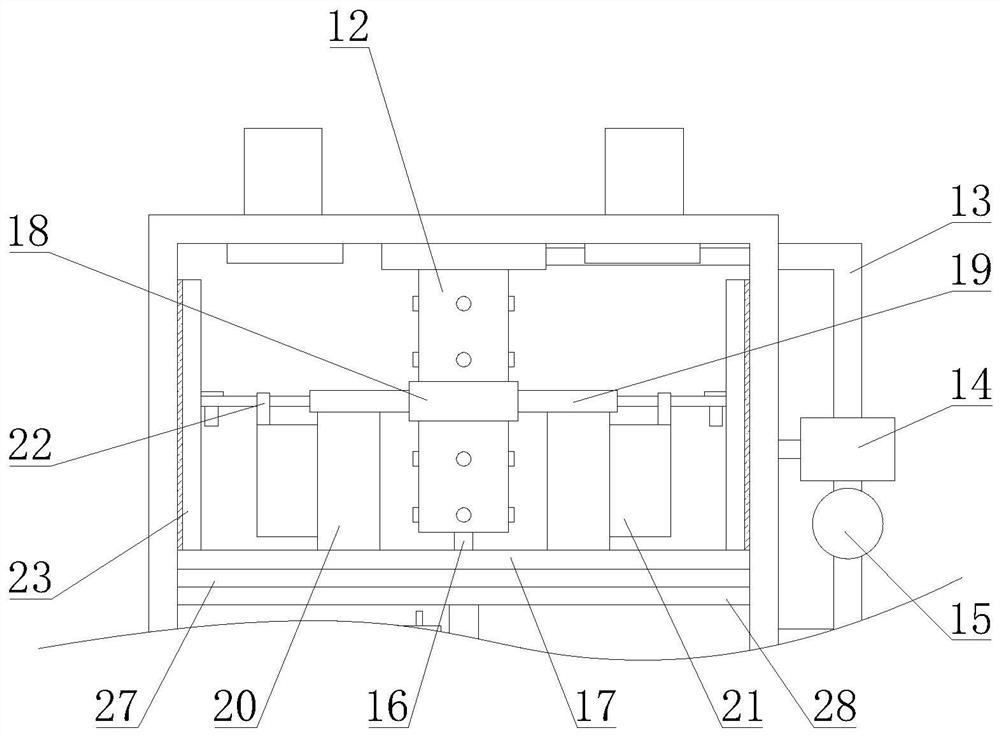

[0044] Such as Figure 1-6As shown, a kind of crispy sesame jujube production equipment proposed by the present invention comprises a housing 1, a stirring assembly 2, a discharge assembly 3, a baking roller group 4, a hot gas recovery pipe 13 and a controller; the discharge assembly 3 is provided with In the middle of the housing 1, it is divided into an upper mixing chamber and a lower baking chamber; one end of the hot gas recovery pipe 13 is connected to the stirring assembly 2, and the other end is connected to the lower baking chamber; the stirring assembly 2 is arranged in the upper mixing chamber; the baking The roller group 4 is in the baking chamber, and multiple groups are arranged from top to bottom to form a connected dynamic baking line. Each group of baking roller group 4 includes a plurality of rotating heating rollers; the stirring assembly 2 includes a mounting cylinder 12, a driving member , motor one, connecting shaft 16, stirring frame one 17, turret 18, c...

Embodiment 2

[0053] Such as Figure 7 Shown, on the basis of above-mentioned embodiment, the driver among the present invention comprises motor three 25 and connecting plate 26; Motor three 25 is arranged on the telescoping link top of cylinder one 19; , and the other end is connected to the stirring frame two 23.

[0054] The present invention is provided with a driving part, and the third motor 25 drives the connecting plate 26 to rotate, so that the second stirring frame 23 rotates, which is convenient for adjusting the angle and position of the stirring end, and enhances the flexibility of stirring.

Embodiment 3

[0056] Such as Figure 8-9 As shown, on the basis of the above-mentioned embodiments, a paving member 6 is arranged in the drying chamber of the present invention; Teeth 36, cylinder two 37 and lifting plate 38; mounting seat 34 is arranged on the chamber wall of the baking chamber; guide table 35 is arranged on the lower end of mounting seat 34; On; the paving teeth 36 are arranged at the lower end of the lifting plate 38 .

[0057] The present invention is equipped with a paving part 6, and the paving tooth 36 is driven up and down by the cylinder 2 37, and the accumulated semi-finished products are pushed away, so as to avoid uneven heating of the product, causing local scorching or weakness, and affecting the taste of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com