Cracking tower for preparing high-purity nitrogen trifluoride

A nitrogen trifluoride, high-purity technology, applied in the field of cracking towers, can solve the problems of destroying the sealing performance of the packaged devices and unfavorable nitrogen trifluoride purification, and achieve the effects of ensuring sealing performance, improving purification, and avoiding rotating gaps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

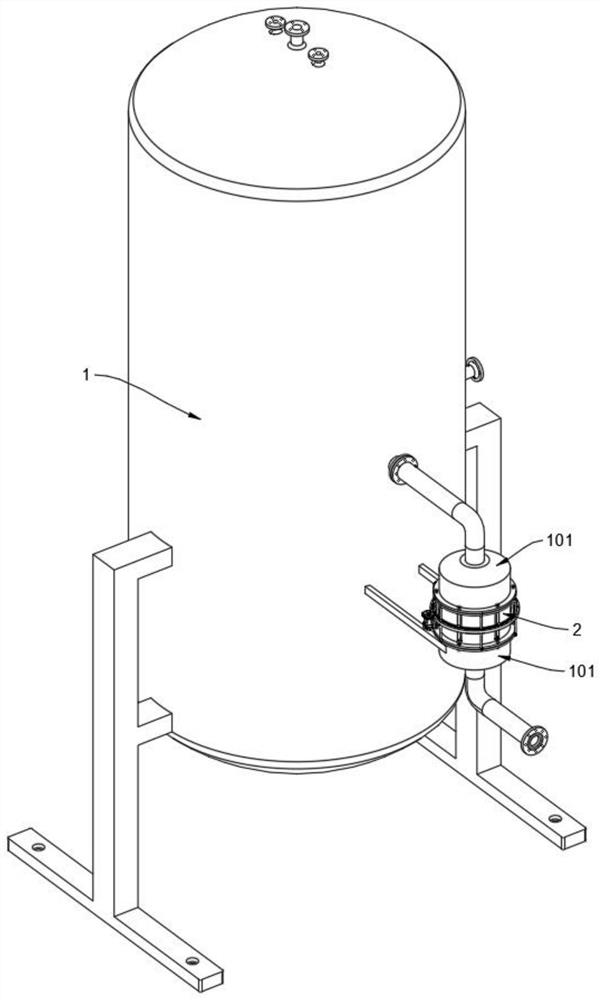

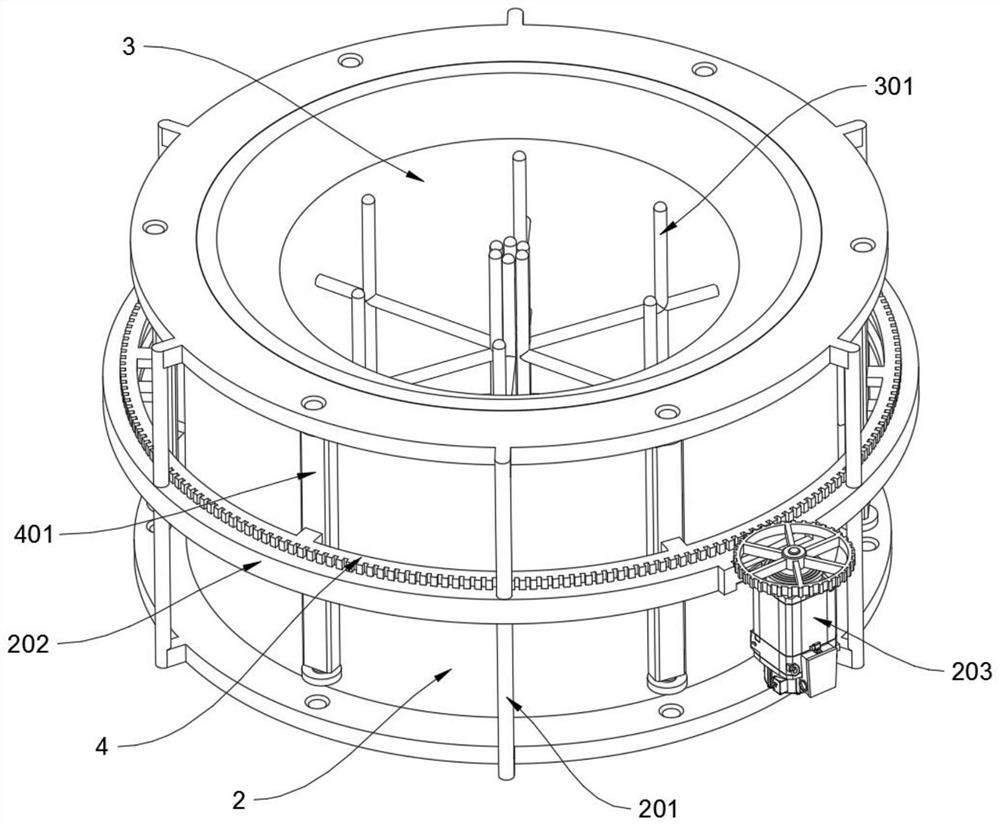

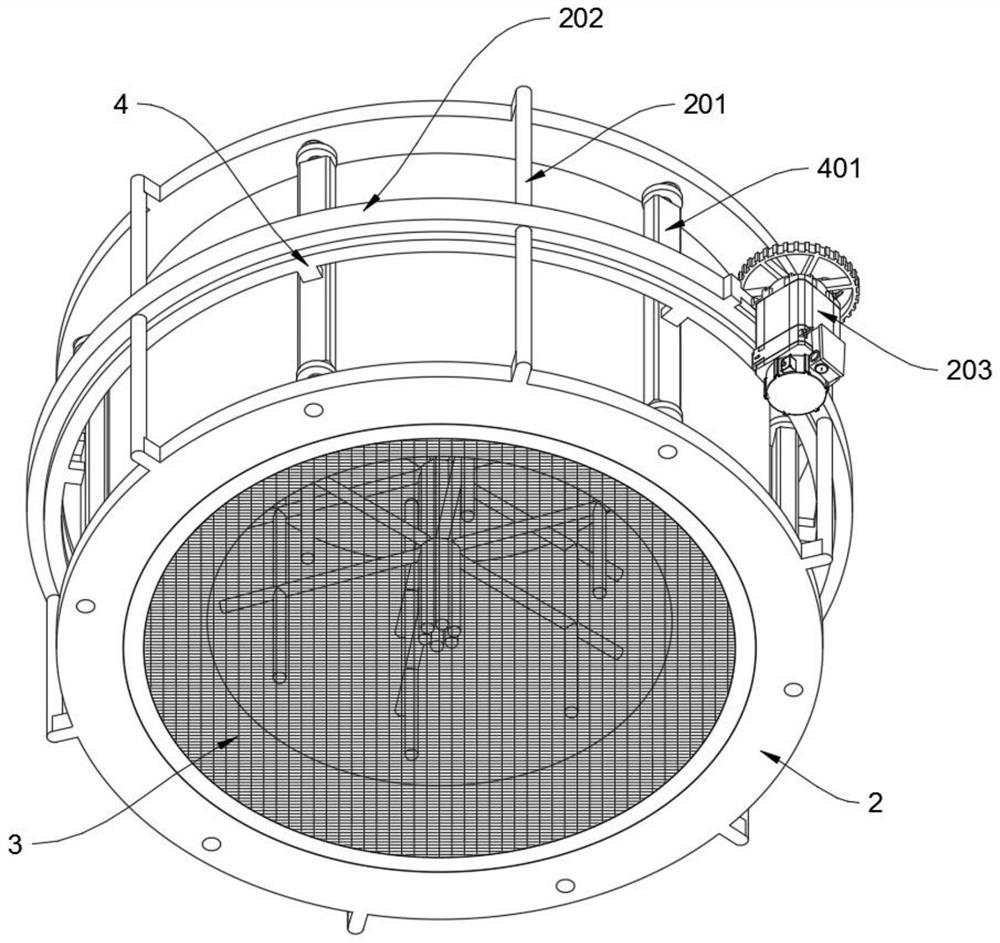

[0032] Such as Figure 1-7 The shown cracking tower for preparing high-purity nitrogen trifluoride includes a cracking tower 1, and the outer lower part of the cracking tower 1 is provided with two gas hoods 101 facing up and down, and the two gas hoods 101 facing up and down are locked. Connected with a filter pipe 2, the interior of the filter pipe 2 is fixedly provided with an inner container 3 for filling active aluminum particles, and the inner container 3 is provided with a stirring mechanism for stirring the active aluminum particles, and the stirring mechanism consists of The driving mechanism drives and stirs the active aluminum particles.

[0033] Such as figure 1 and figure 2 As shown, in the present embodiment, the upper L-shaped air duct and the lower L-shaped air duct are communicated with the two up and down facing air hoods 101 respectively, and one end of the upper L-shaped air duct is connected to the upper end air hood. 101 is connected, and the other en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com