Efficient recycling and regenerating treatment process for waste solar heat collector

A solar collector and solar collector tube technology, applied in the field of solar energy, can solve the problems of difficulty in ensuring that the inner wall of the collector tube is cleaned, the efficiency of the collector tube is low, etc., so as to reduce the labor workload of workers, improve the high-efficiency recovery efficiency, and improve the high-efficiency recovery and recycling rate. The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

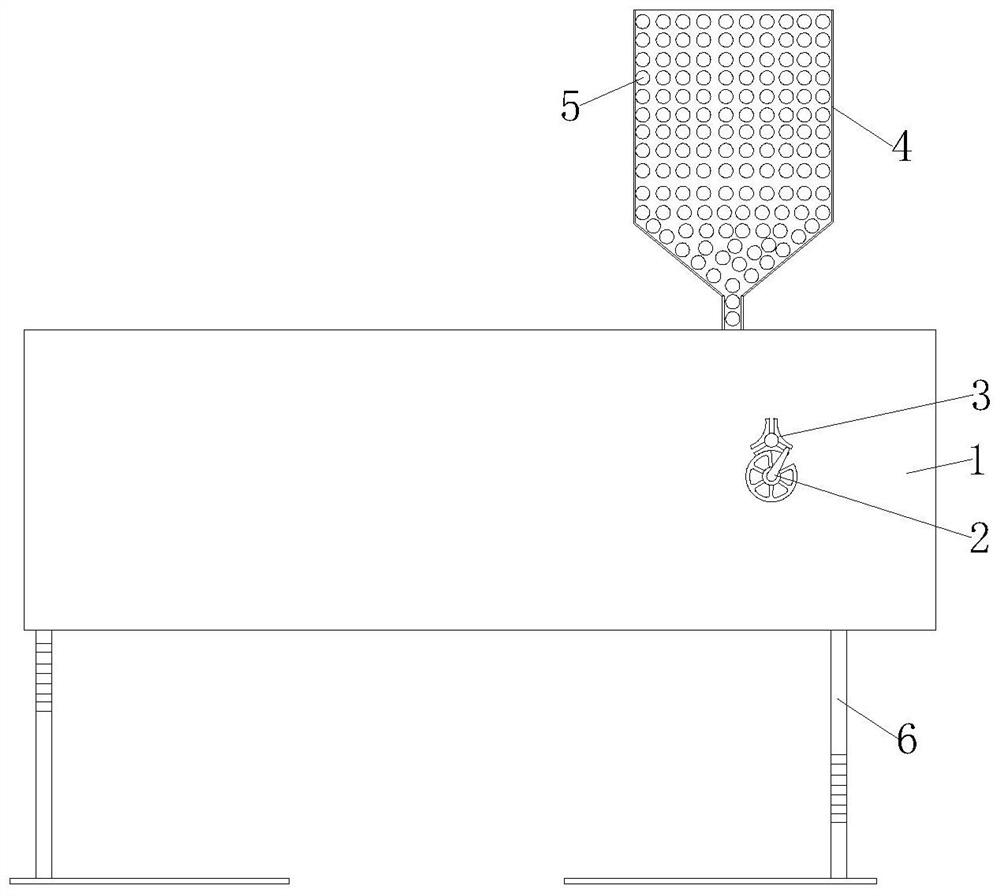

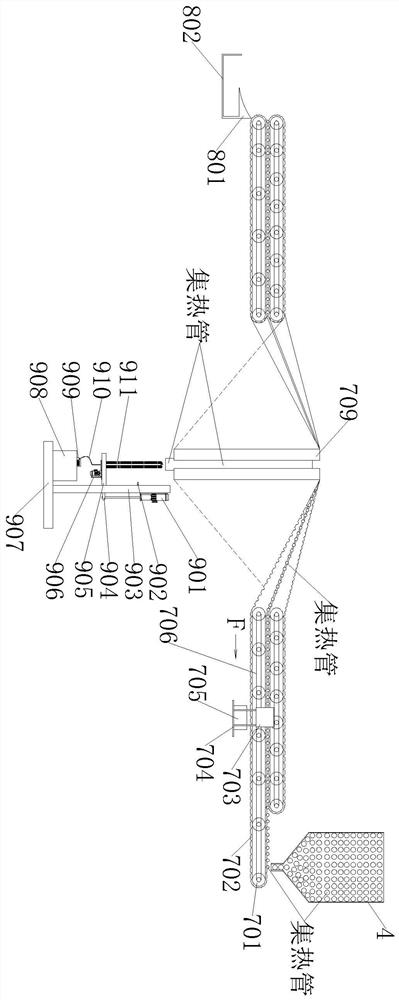

[0049] see Figure 1-9 It is a schematic diagram of the overall structure of a high-efficiency recovery and regeneration process for waste solar collectors;

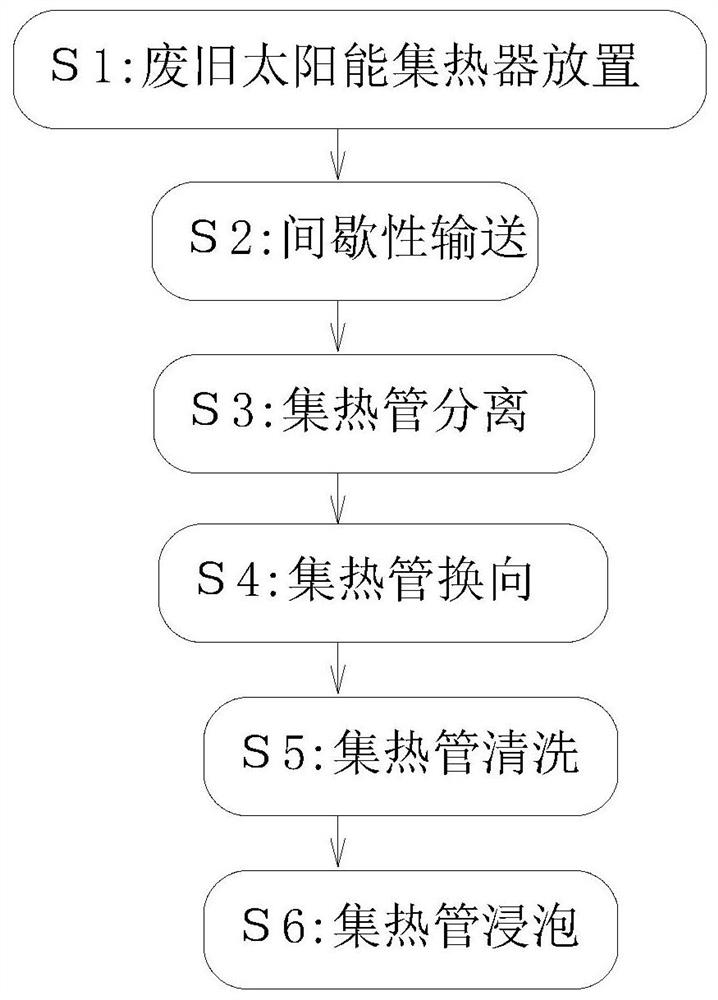

[0050] A high-efficiency recovery and regeneration treatment process for waste solar heat collectors, comprising the following steps:

[0051] S1. Placement of waste solar heat collectors: collect the waste solar heat collectors in the waste heat collector storage bucket 4, and make the two ends of each waste solar heat collectors consistent;

[0052] S2. Intermittent transportation: intermittently move the waste solar heat collecting tubes placed in the waste heat collecting tube storage bucket 4 through the intermittent conveying mechanism 7 in step S1;

[0053] S3. Separation of heat collecting tubes: separate each waste solar heat collecting tube that moves intermittently in step S2, by absorbing the asbestos plug at the front end of the waste Pull out, so as to realize the separation of the vacuum tube inner tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com