Assembling equipment and method for high-strength ceramic cylinder liner

A technology for assembling equipment and ceramic cylinders, which is applied in the field of cylinder liner processing, can solve problems such as affecting assembly efficiency, large energy consumption loss, and poor application prospects, and achieve the effects of reducing equipment energy consumption, high degree of automation, and high flexibility in operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

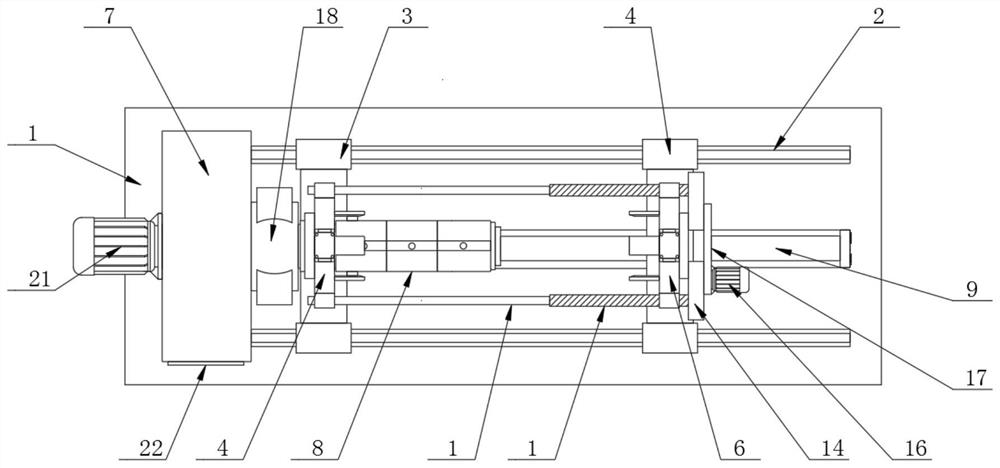

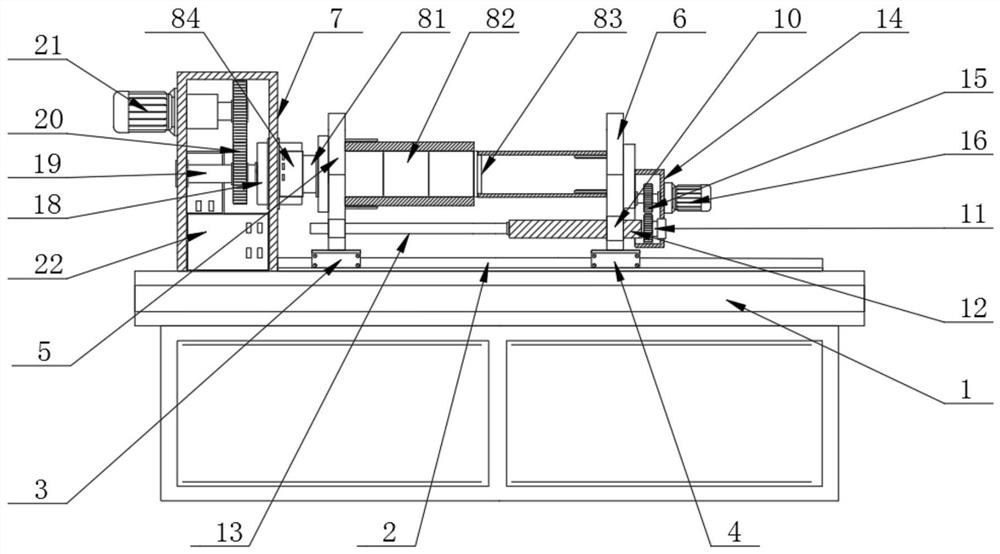

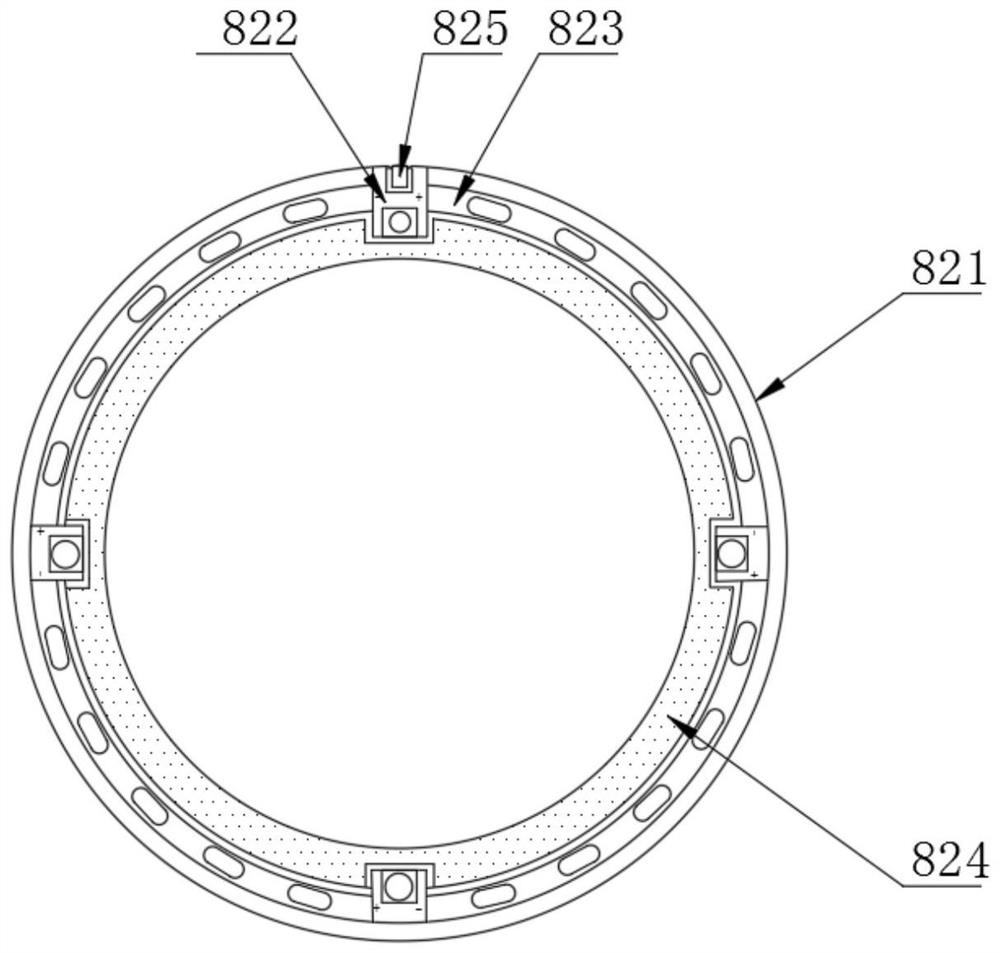

[0034] Such as figure 1 , 3 As shown in , 4 and 6, a high-strength ceramic cylinder liner assembly equipment includes an assembly platform 1 and a main controller 22, and also includes a linear motor 9 and a split heater 8 on the assembly platform 1 and a sliding The outer pneumatic clamping disc 5 and the inner pneumatic clamping disc 6 on the assembly platform 1;

[0035] The outer pneumatic clamping disk 5 and the clamped metal jacket are movably sleeved on the outside of the split heater 8, and after the main controller 22 sets the heating parameters of the split heater 8, the split heater 8 is used to heat the metal. The coat is heat treated;

[0036] The linear motor 9 pushes the heat-treated metal jacket and the ceramic lining clamped by the inner pneumatic clamping disc 6 for shrink-fit assembly.

[0037] The assembly platform 1 is located on both sides of the linear motor 9 and is symmetrically provided with guide rails 2, and the guide rails 2 are provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com