Protective cutting treatment machine for seamless metal pipe

A technology of seamless metal pipe and processing machine, which is applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of affecting production efficiency, small thickness of seamless metal pipe, and difficult to trace back the deformation of the nozzle, so as to improve the integrity performance, improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

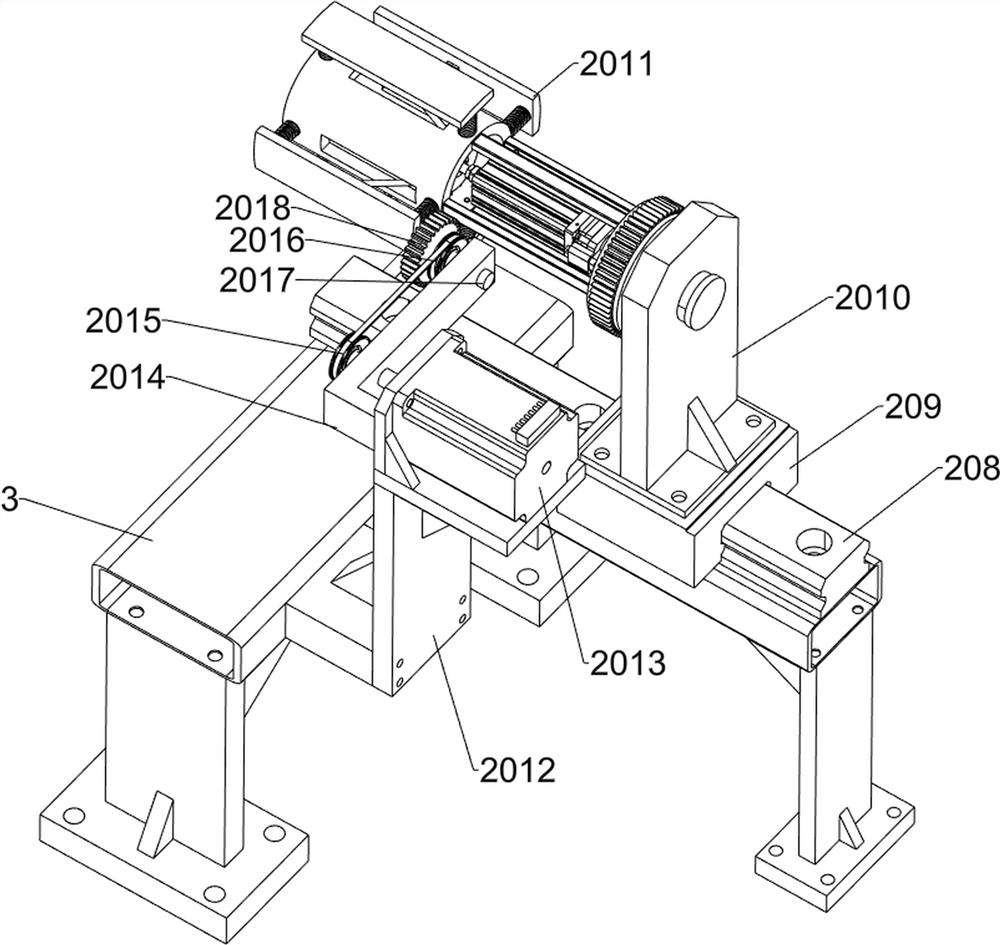

[0032] Protection cutting a seamless metal pipe handling machine, such as Figure 1-3 Shown, it comprises a first chassis, the second chassis 2, the chassis 3 of the third storage box 4, tool 5, the top scoring side branch protection system and cutting system; solid left first chassis 1 connected with the second chassis 2; right first chassis 1 is fixed to a third frame 3; the front side of the first chassis 1 is mounted and a storage box 4 kit 5; provided in kit storage box 4 5 left; the second chassis 2 is mounted above the scribe mark for the top side branch scoring the outer surface of the metal pipe system; side branch 3 is connected to a third chassis top scoring system; third chassis 3 above the front mounting It has protected metal pipe cutting system for cutting and polishing the section.

[0033] Working principle: before the device is in operation, the metal tube is placed in the information processing apparatus the storage box 4, the device is staff to ensure a smooth w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com