Complex microbial inoculant as well as preparation method and application thereof

A technology of compound bacterial agent and pediococcus, which is applied in the field of animal husbandry, can solve the problems of dry matter loss and low fermentation quality, and achieve the effects of strong survival ability, large lactic acid production, and high specificity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

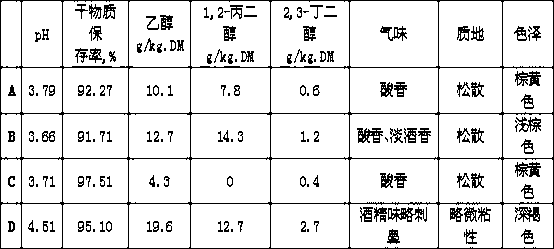

Examples

Embodiment 1

[0021] Rhamnosus was activated and cultured at 34 °C for 18 h, inoculated into MRS medium, and cultured statically at 37 °C for 24 hours, so that the final number of viable bacteria reached 3.5×10 9 CFU / ml, to obtain Lactobacillus rhamnosus suspension;

[0022] The ethanol-resistant Pediococcus was activated and cultured at 34 °C for 18 h, inoculated into MRS medium, and cultured statically at 33 °C for 24 hours, so that the final number of viable bacteria reached 3.5×10 9 CFU / ml, to obtain ethanol-resistant Pediococcus suspension;

[0023] Lactobacillus plantarum was activated and cultured at 37 °C for 18 h, and the activated bacterial solution was inoculated into the MRS broth enrichment medium, cultured in the dark at 37 °C, and cultured on a constant temperature shaker at 150 rpm so that the final number of viable bacteria reached 5×10 10 CFU / ml, to obtain a suspension of Lactobacillus plantarum;

[0024] Lactobacillus Brucella was activated and cultured at 37 °C for 18 ...

Embodiment 2

[0034] Rhamnosus was activated and cultured at 34 °C for 18 h, inoculated into MRS medium, and cultured statically at 37 °C for 24 hours, so that the final number of viable bacteria reached 3.5×10 9 CFU / ml, to obtain Lactobacillus rhamnosus suspension;

[0035] After the ethanol-resistant Pediococcus was activated and cultured at 34 °C for 18 h, it was inoculated into MRS medium, and cultured statically at 33 °C for 24 hours, so that the final number of viable bacteria reached 3.5×10 9 CFU / ml, to obtain ethanol-resistant Pediococcus suspension;

[0036] The obtained Lactobacillus rhamnosus suspension and the ethanol-resistant Pediococcus suspension are mixed according to a volume ratio of 1:1.5 to prepare a composite bacterial agent;

[0037] Harvest the complete ear of corn with bracts in the milk ripening stage, and use a hammer feed mill to crush the fresh samples until the grains are broken, and add the above-mentioned compound bacterial agent at a dosage of 1×10 5 CFU / ...

Embodiment 3

[0039] Rhamnosus was activated and cultured at 34 °C for 18 h, inoculated into MRS medium, and cultured statically at 37 °C for 24 hours, so that the final number of viable bacteria reached 3.5×10 9 CFU / ml, to obtain Lactobacillus rhamnosus suspension;

[0040] The ethanol-resistant Pediococcus was activated and cultured at 34 °C for 18 h, inoculated into MRS medium, and cultured statically at 33 °C for 24 hours, so that the final number of viable bacteria reached 3.5×10 9 CFU / ml, to obtain ethanol-resistant Pediococcus suspension;

[0041] The obtained Lactobacillus rhamnosus suspension and the ethanol-resistant Pediococcus suspension are mixed according to a volume ratio of 1:1 to prepare a composite bacterial agent;

[0042] Harvest the complete ear of corn with bracts in the milk ripening stage, and use a hammer feed mill to crush the fresh samples until the grains are broken, and add the above-mentioned compound bacterial agent at a dosage of 1×10 5 CFU / g, mixed evenly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com