Clamping device for intelligent power battery of new energy vehicles

A technology for new energy vehicles and power batteries, which is applied in workpiece clamping devices, battery assembly machines, and secondary battery manufacturing. , the effect of easy clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

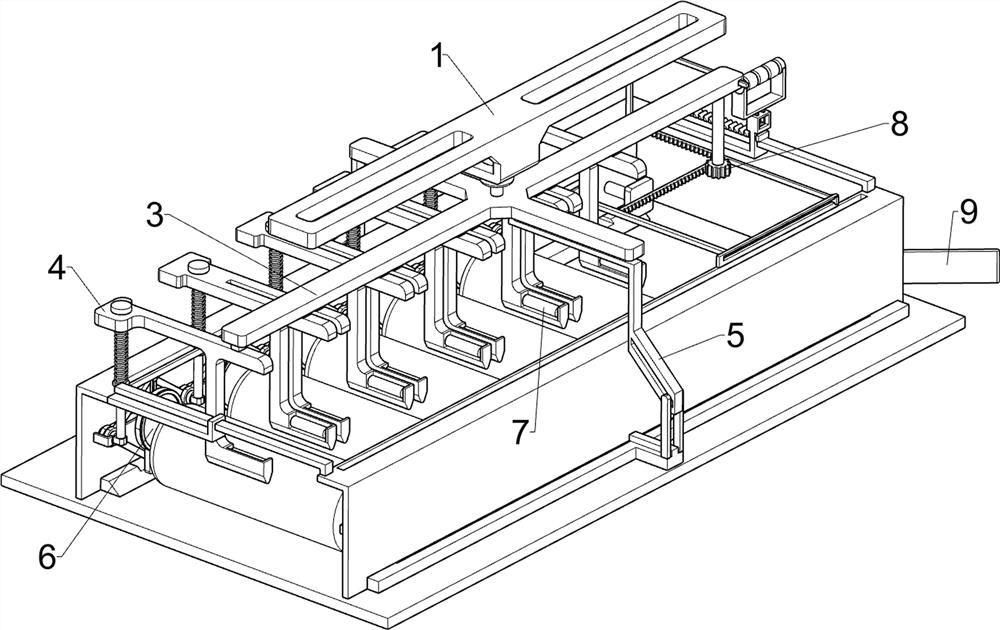

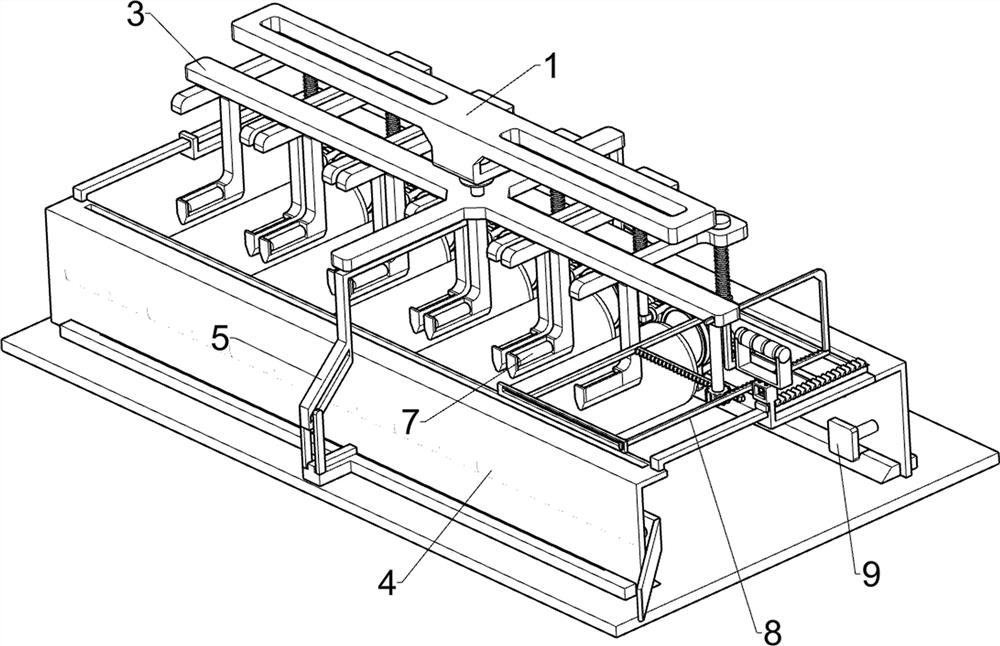

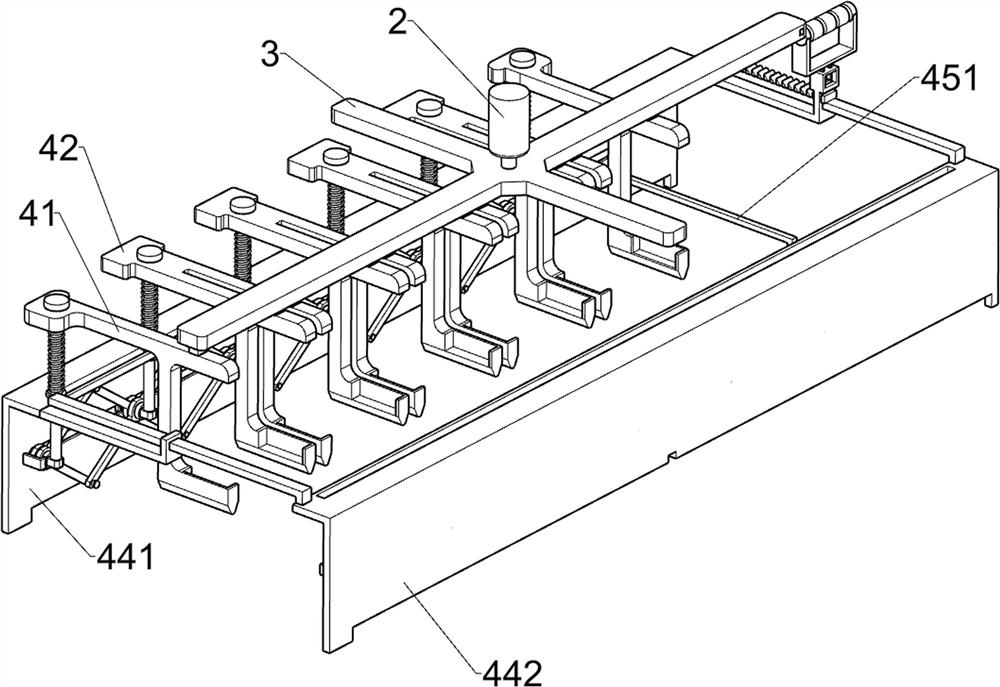

[0038] The clamping device of the intelligent power battery of the new energy vehicle, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 with Figure 10 As shown, it includes a first fixed frame 1, an electric push rod 2, a cross 3, an arrangement mechanism 4 and a shoveling mechanism 5, an electric push rod 2 is fixedly connected under the first fixed frame 1, and one end of the telescopic shaft of the electric push rod 2 passes through The cross 3 is connected by welding, the cross 3 is provided with an arrangement mechanism 4 for evenly arranging the power batteries, and the cross 3 is provided with a scooping mechanism 5 for scooping up the power batteries.

[0039] The arrangement mechanism 4 includes a first sliding frame 41, a second sliding frame 42, a slide bar 43, a first return spring 44, a fixed side plate 441, a sliding side plate 442, a sliding block 45, a connecting bar 451, a connecting plate ...

Embodiment 2

[0044] On the basis of Example 1, such as Figure 11 , Figure 12 with Figure 13 As shown, a clamping mechanism 6 is also included. The clamping mechanism 6 is arranged on the side where the fixed side plate 441 and the sliding side plate 442 are close to each other. The clamping mechanism 6 is used to better clamp the power battery. The clamping mechanism 6 includes a sliding bar 61, a sliding splint 62 and a rubber ring 63. The fixed side plate 441 and the sliding side plate 442 are linearly distributed inside and are slidably connected with five sliding bars 61. The sliding bar 61 is located between the fixed side plate 441 and the On the sides where the sliding side plates 442 are close to each other, the sliding bar 61 is slidably matched with the telescopic frame 47. The sliding splint 62 is slidably connected to the sliding bar 61. The sliding splint 62 is used to clamp the power battery, and the sliding splint 62 passes through the sliding In the bar 61 , the right ...

Embodiment 3

[0047] On the basis of Example 2, such as Figure 14 As shown, it also includes an anti-scratch roller 7, the bottom of the first sliding frame 41 is rotatably connected with the anti-scratch roller 7, the bottom of the second sliding frame 42 is rotatably connected with a pair of anti-scratch rollers 7, the anti-scratch roller 7 Used to prevent the surface of the power battery from being scratched.

[0048] During the downward movement of the first carriage 41 and the second carriage 42, the anti-scratch roller 7 in contact with the power battery will roll through the anti-scratch roller 7 to prevent the surface of the power battery from being scratched.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com