Environment-friendly degradable preservative film and preparation method thereof

A fresh-keeping film and environmental protection technology, which is applied in the field of environmentally-friendly degradable plastic wrap and its preparation, can solve the problems that the plastic wrap is easy to break, the plastic wrap is not easy to degrade, and the living environment is polluted, so as to ensure the thickness, improve the processing quality, and ensure the balance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

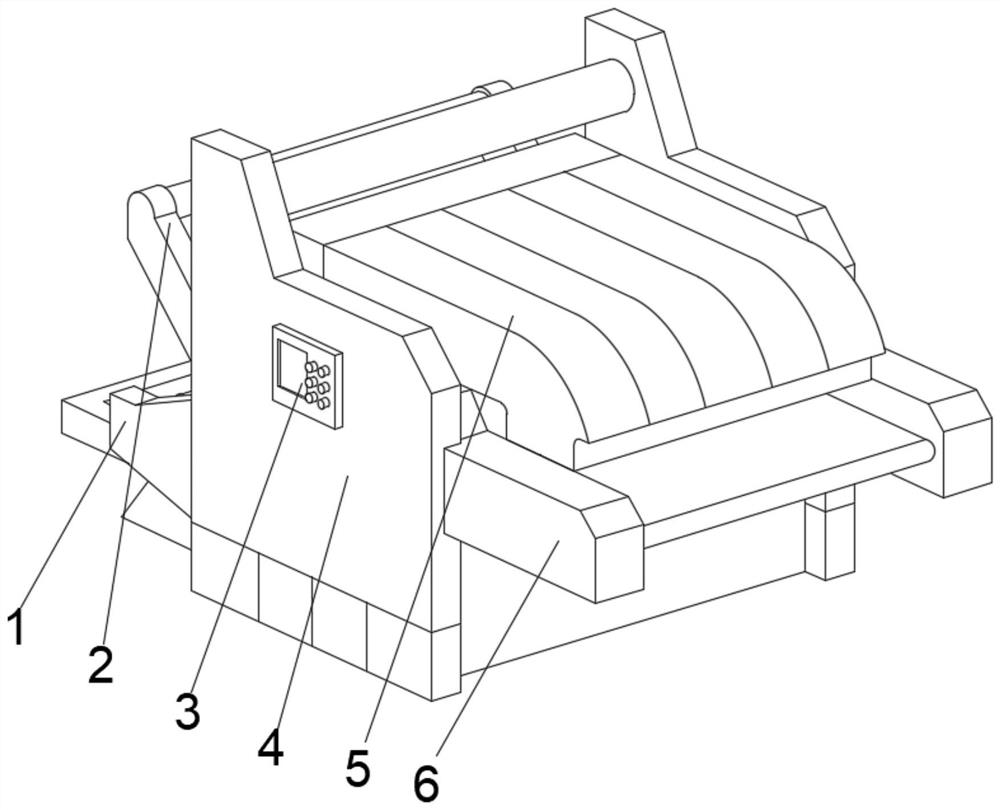

[0039] see Figure 1-5, the present invention provides a technical solution: an environment-friendly and degradable fresh-keeping film preparation device, comprising a preparation main body 4, an installation part 6 is arranged on the top of the right outer wall of the preparation main body 4, and a preparation Device 5, the control panel 3 is fixedly connected to the middle position of the front top of the preparation main body 4, the left outer wall of the preparation main body 4 is located on both sides of the preparation device 5, and adjustment rollers 2 are arranged, and the bottom of the left outer wall of the preparation main body 5 is fixedly connected with Collection shelf 1.

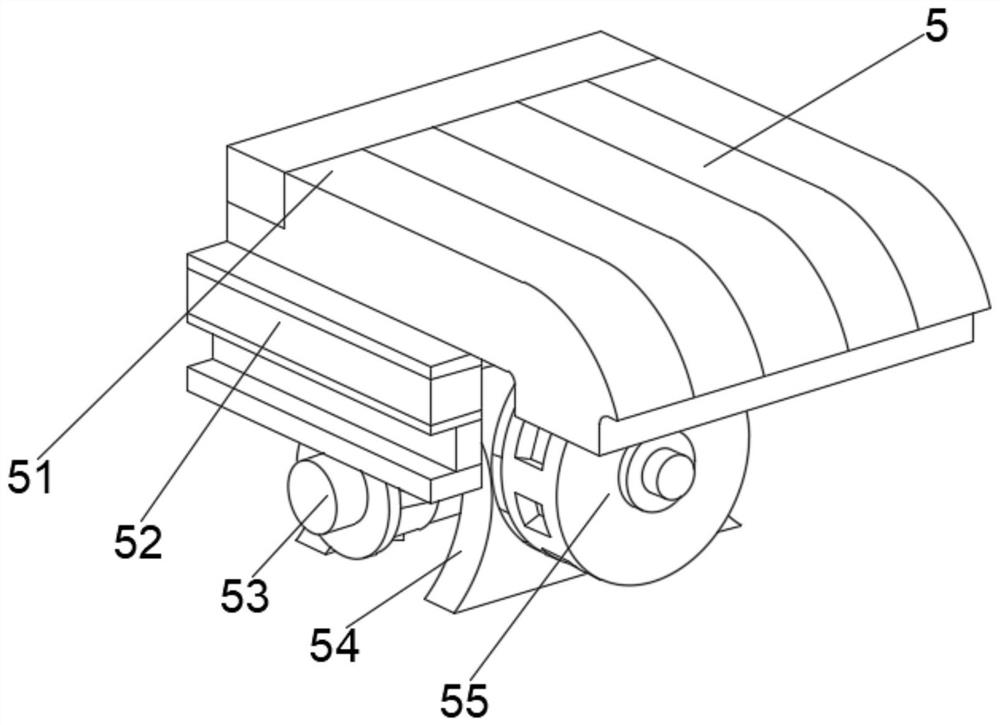

[0040] Wherein, the preparation device 5 includes a control top cover 51, the bottom two sides of the control top cover 51 are fixedly connected with outer partitions 52, and the outer partition 52 is provided with an adjustment mechanism 53 at the middle position near the bottom of one side o...

Embodiment 2

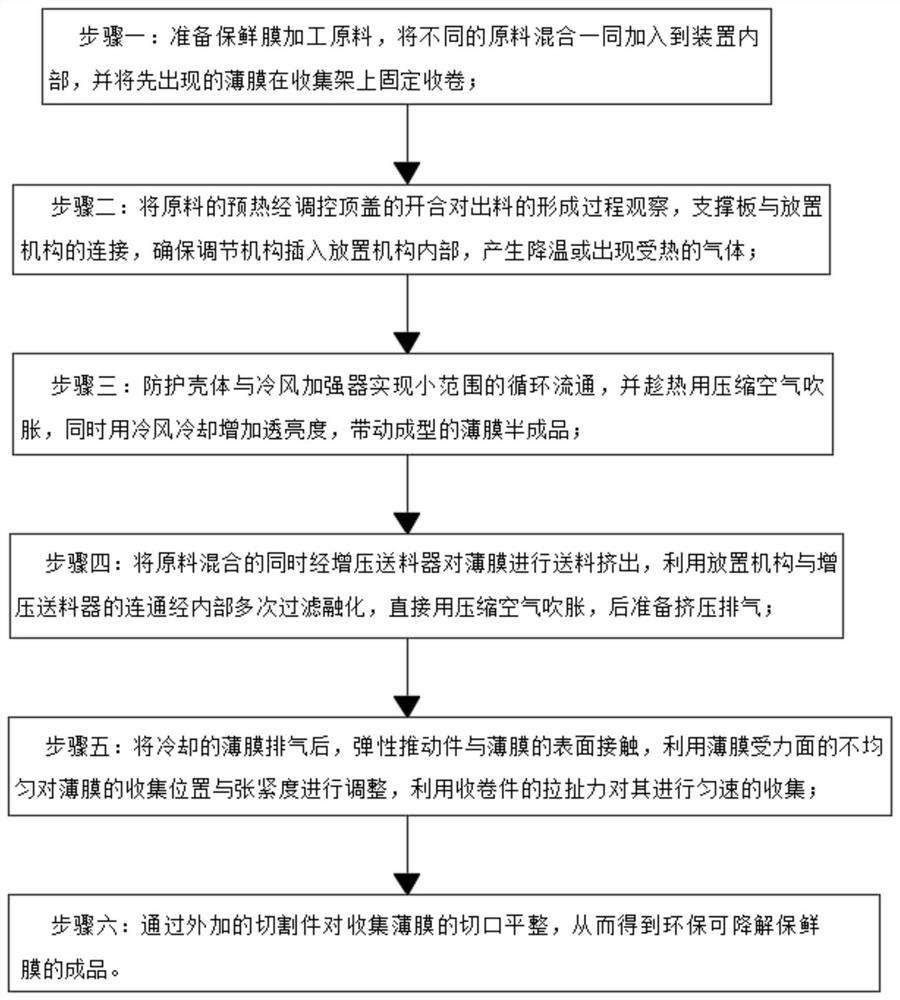

[0045] see Figure 1-5 , on the basis of Embodiment 1, the present invention provides a technical solution: a method for preparing an environmentally friendly and degradable plastic wrap, step 1: prepare raw materials for processing plastic wrap, mix different raw materials and add them to the inside of the device, and mix the first The film that occurs is fixedly wound on the collecting rack 1;

[0046] Step 2: Preheat the raw material and observe the formation process of the discharge by adjusting the opening and closing of the top cover 51. The connection between the support plate 54 and the placement mechanism 55 ensures that the adjustment mechanism 53 is inserted into the interior of the placement mechanism 55, resulting in cooling or heating. gas;

[0047] Step 3: The protective casing 532 and the cold air intensifier 534 realize a small-scale circulation, and use compressed air to inflate while hot, and at the same time use cold air to cool to increase the transparenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com