TPU high-pressure water hose production process and full-automatic production equipment thereof

A technology of production equipment and production process, which is applied in the field of TPU high-pressure hose production process and its fully automatic production equipment, can solve the problems of oil resistance, wear resistance, and poor low temperature resistance of the hose, reduce inventory, and have strong low temperature resistance. , The effect of strong pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

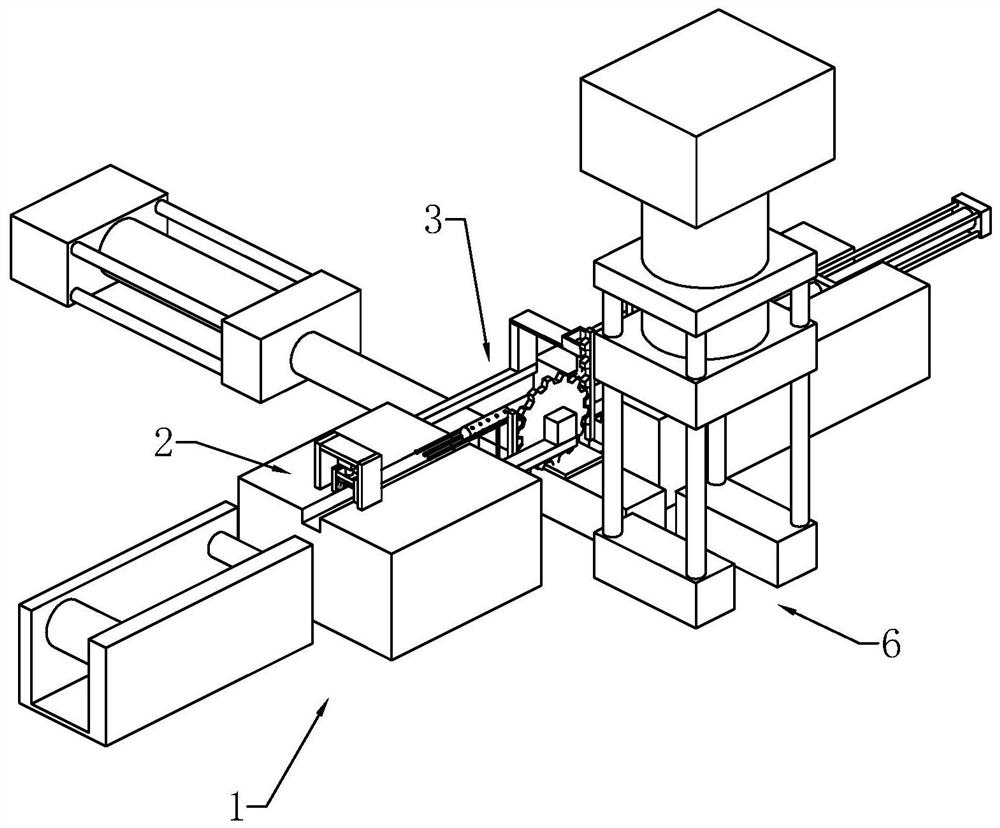

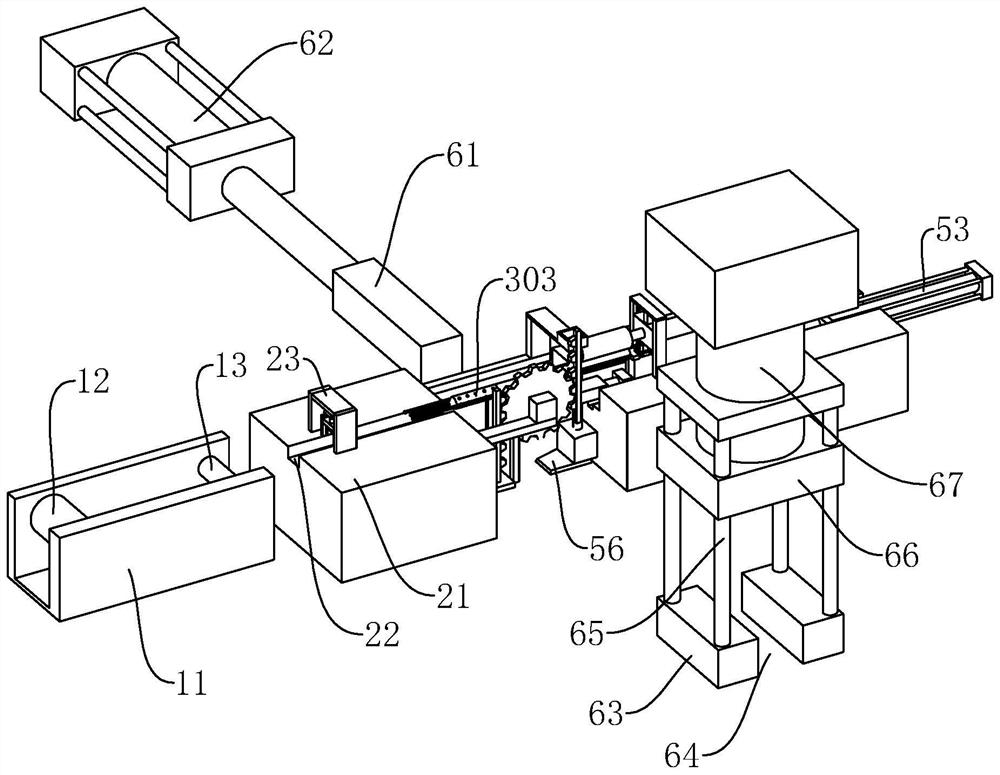

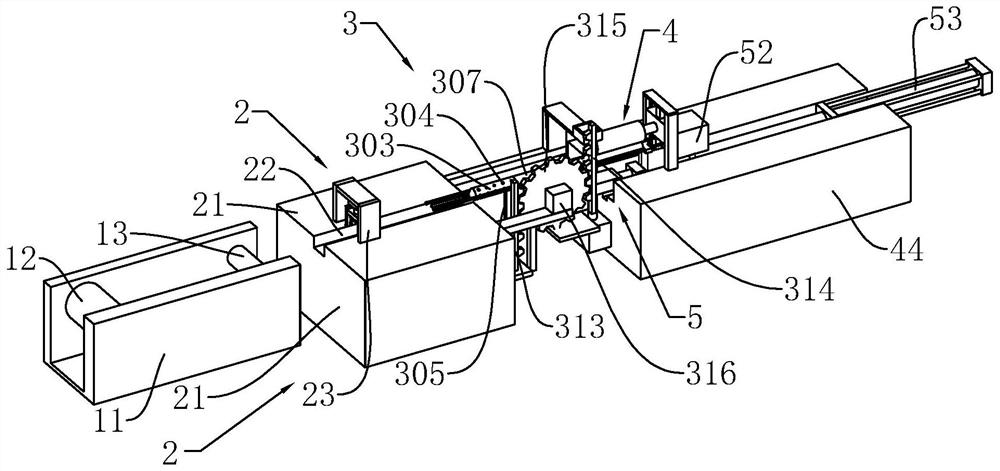

[0039]The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0040] This specific embodiment is only an explanation of the present invention, and it is not a limitation of the present invention. Those skilled in the art can make modifications to this embodiment without creative contribution as required after reading this specification, but as long as they are within the rights of the present invention All claims are protected by patent law.

[0041] A TPU high-pressure hose production process, comprising the following steps:

[0042] a. Base fabric pretreatment: base fabric rolls with low shrinkage rate and high strength are selected for the gray fabric; among them, the shrinkage rate is 0.6-0.8%; the strength is 300-500mPa; water-based PU glue is coated on the gray fabric with a scraper coater Or TPU hot melt adhesive, with a thickness of 0.01-0.05mm, dried and rolled;

[0043] b. Bonding of the base fabric and the T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com