Clamp synchronous control system, clamp device and drilling machine

A synchronous control and clamp technology, applied in the direction of fluid pressure actuating device, drill pipe, drill pipe, etc., can solve problems such as damage to the threaded end of the drill pipe and low shackle efficiency, so as to increase the unloading function and improve the safety. , the effect of reducing the probability of falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

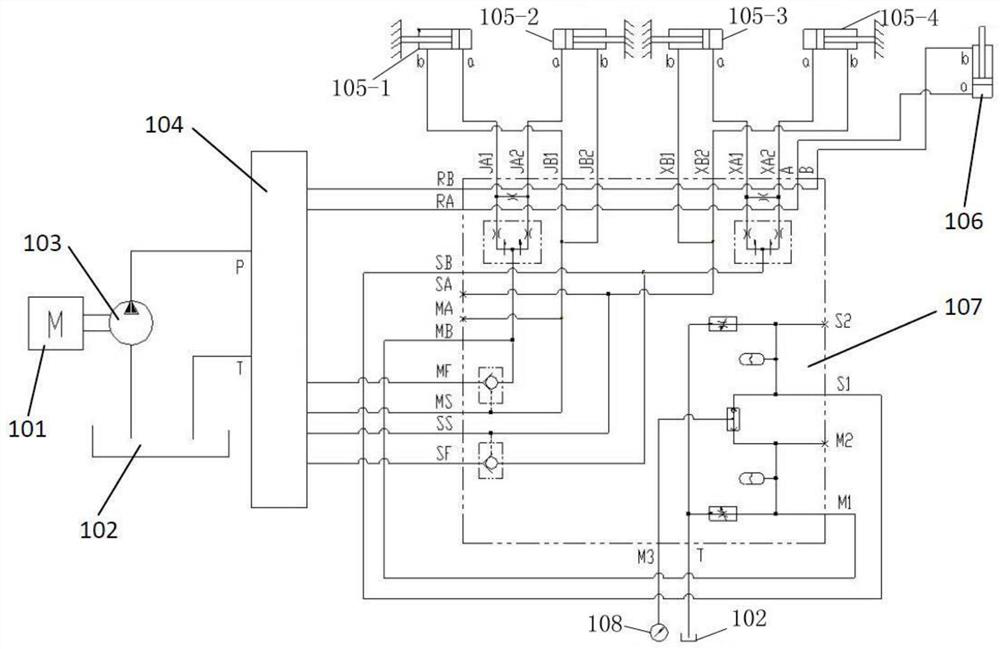

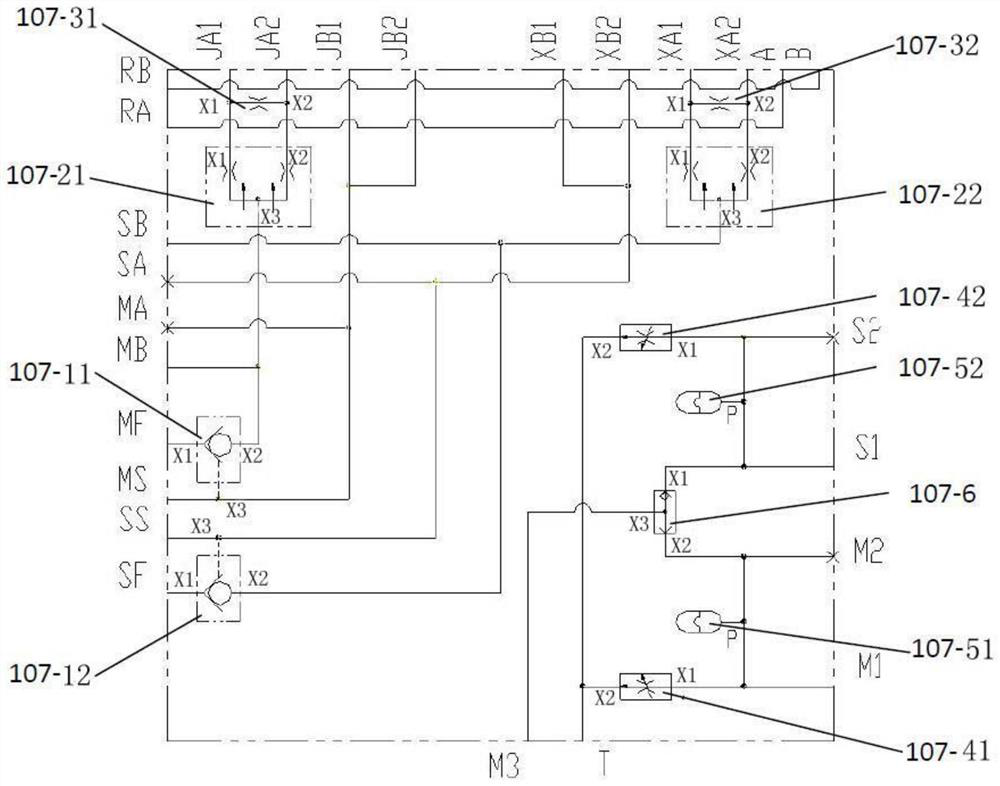

[0024] A clamp synchronous control system, including: an oil supply unit, used to provide hydraulic oil required for work; a synchronous control valve block, used to balance the hydraulic oil flowing to each clamp, so as to maintain the clamping cylinders of each clamp synchronized movement.

[0025] Such as figure 1 , figure 2 As shown, the oil supply unit includes an engine (or motor) 101, the engine 101 is connected to the hydraulic pump 103, the oil suction port of the hydraulic pump 103 communicates with the hydraulic oil tank 102, and the oil outlet of the hydraulic pump 103 is connected to the P port of the multi-way valve 104. (high pressure port), the T port (low pressure port) of the multi-way valve 104 is connected with the hydraulic oil tank 102 ; the oil outlet of the multi-way valve 104 is connected with the synchronous control valve block 107 .

[0026] The MF port, MS port, SS port and SF port of the synchronous control valve block 107 are respectively conne...

Embodiment 2

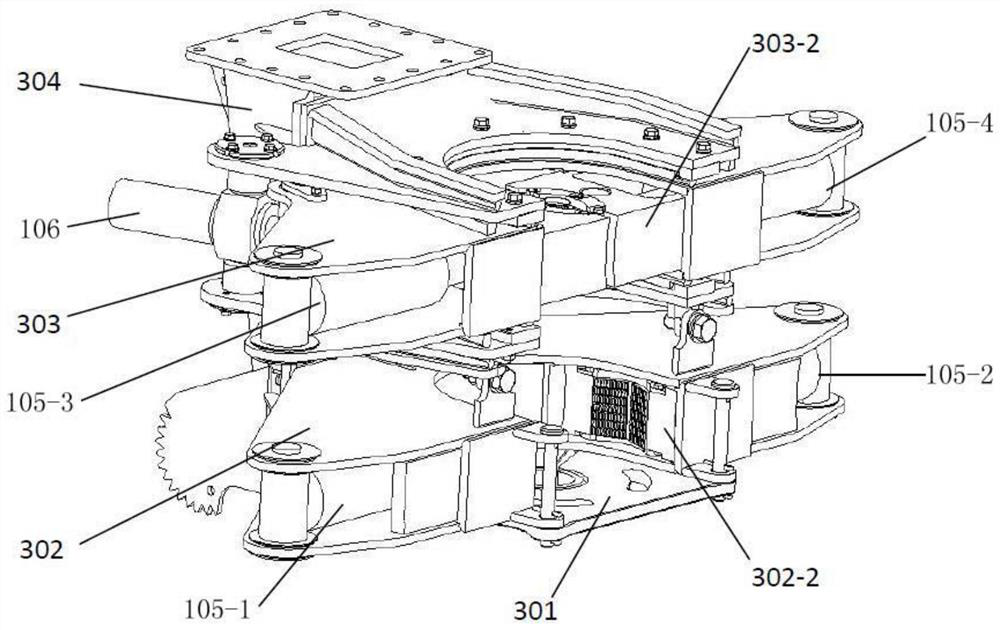

[0033] Based on the clamp synchronous control system described in the first embodiment, this embodiment provides a clamp device configured with the clamp synchronous control system described in the first embodiment.

[0034] Such as image 3 As shown, the clamp device includes clamp one 302 installed on the clamp base 304, clamp two 303, clamp rotary cylinder 106 and guide device 301; clamp rotary cylinder 106 is hinged with clamp two 303; clamp one 302 Including clamp-left clamping oil cylinder 105-1, clamp-right clamping oil cylinder 105-2, clamp-1 installed on clamp-left clamping oil cylinder 105-1 and clamp-right clamping oil cylinder 105-2 Tiger tooth seat 302-2; clamp 2 303 includes clamp 2 left clamping oil cylinder 105-3, clamp 2 right clamping oil cylinder 105-4, installed on clamp 2 left clamping oil cylinder 105-3 and clamp 2 right Clamp two cane teeth seat 303-2 of clamping oil cylinder 105-4.

Embodiment 3

[0036] Based on the clamp synchronous control system described in the first embodiment and the clamp device described in the second embodiment, this embodiment provides a drilling rig, and the drilling machine is equipped with the clamp device described in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com