Connection auxiliary equipment for transmission with driving belt pulley

A technology for driving pulleys and auxiliary equipment, applied in belts/chains/gears, mechanical equipment, transmissions, etc., it can solve the problems of driven and active pulleys of large and small size, and reduce the failure rate, improve practicability, and save connection time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

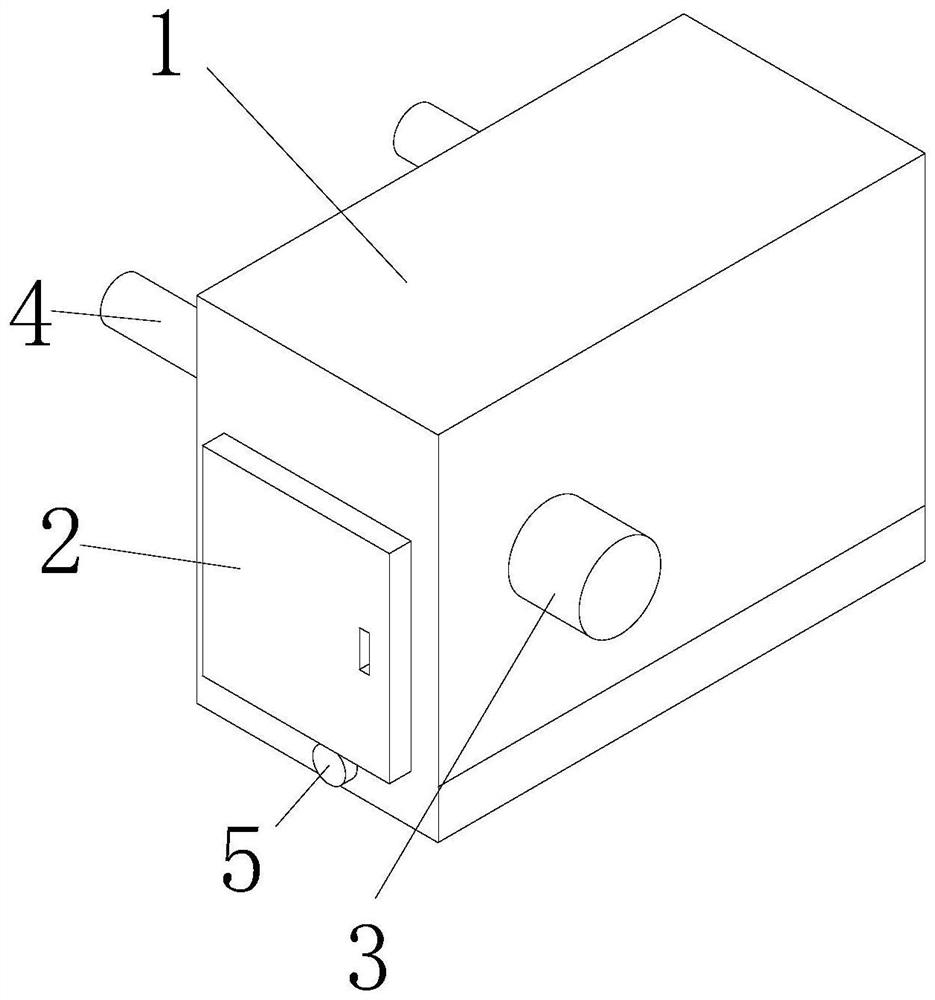

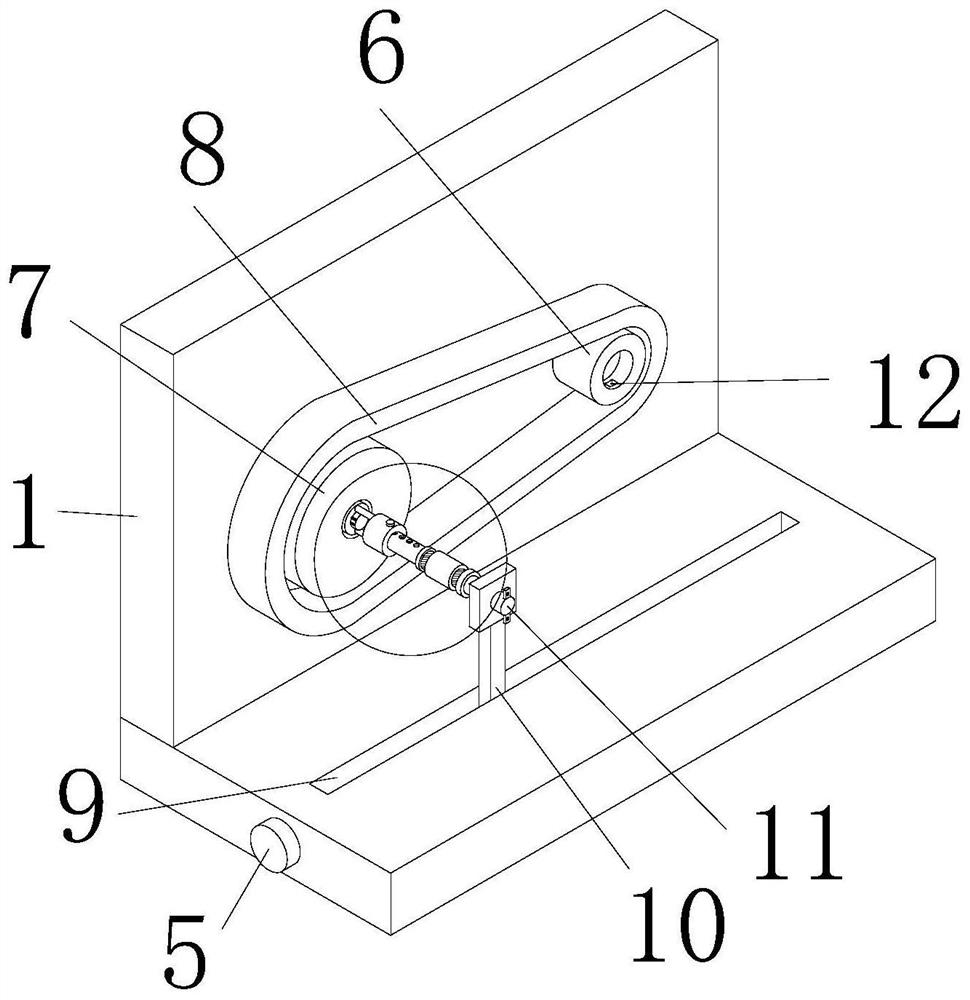

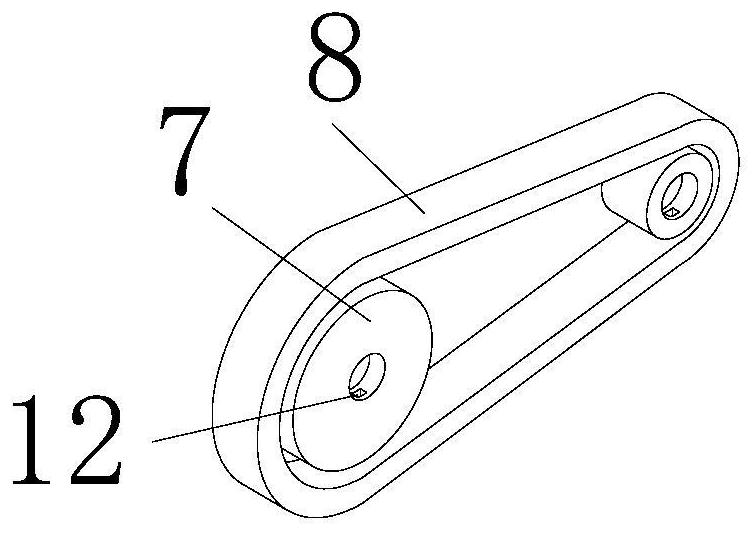

[0039] see Figure 1-8 , the present invention provides a technical solution: a kind of connection auxiliary equipment for driving pulley transmission, including a transmission box 1, a door panel 2 is arranged on the front surface of the transmission box 1, a motor 3 is fixedly connected to the right surface of the transmission box 1, and the transmission The front and rear sides of the left surface of the box 1 are rotatably connected with transmission shafts 4, and the right ends of the two transmission shafts 4 run through the transmission box 1 and extend to the inside of the transmission box 1, and the left surface of the transmission box 1 is rotatably connected with a small pulley 6 and large pulley 7, small pulley 6 and large pulley 7 are respectively located at the front and rear sides of the inner right surface of transmission case 1, and the left ends of two drive shafts 4 are fixedly connected with small pulley 6 and large pulley 7 respectively, small pulley 6 and ...

Embodiment 2

[0043] see Figure 1-8 , on the basis of Embodiment 1, the connection device includes a hollow fixed block 23, the fixed block 23 is arranged inside the transmission box 1, the right surface of the fixed block 23 is fixedly connected with a fixed rod 22, and the right end of the fixed rod 22 is fixedly connected There is a connecting sleeve 20 which is hollow inside, and the inside of the connecting sleeve 20 is slidingly connected with an adjusting rod 18, and the right end of the adjusting rod 18 extends out of the connecting sleeve 20, and the opposite ends of the adjusting rod 18 and the connecting rod 11 are fixedly connected with mutually compatible bolts Rod 17, two bolt rods 17 are threaded with bolt sleeves 16, the adjusting rod 18 and the connecting rod 11 are fixedly sleeved with limit rings 15, and the two limit rings 15 are respectively located on the left and right sides of the bolt sleeves 16;

[0044] Further, the top surface of the adjusting rod 18 is arranged...

Embodiment 3

[0046] see Figure 1-8 , on the basis of Embodiment 1 and Embodiment 2, the fixing device includes a rotating shaft 24, the rotating shaft 24 is rotatably connected to the right surface of the fixed block 23, and the outer wall of the rotating shaft 24 is fixedly connected with a protrusion 25, and the setting of the protrusion 25 can It is more convenient to rotate the rotating shaft 24, the left end of the rotating shaft 24 runs through the fixed block 23 and extends to the inside of the fixed block 23, the left end of the rotating shaft 24 is fixedly connected with a rotating rod 27, and the upper and lower ends of the rotating rod 27 are fixedly connected with a cam 28, two The opposite end of the cam 28 is provided with an arc-shaped connecting plate 29, and the two cams 28 are respectively in contact with the two connecting plates 29, and the opposite sides of the two connecting plates 29 are fixedly connected with two springs 30, and the two springs The opposite ends of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com