Intelligent disconnecting link system

A technology of intelligent knife and isolation knife switch, applied in the direction of electrical components, etc., can solve the problems of reduced clamping force of the isolation knife switch interface, negative impact on safety production, economic and social benefits, overheating, etc., to facilitate replacement and maintenance. , the effect of increasing strength and improving transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

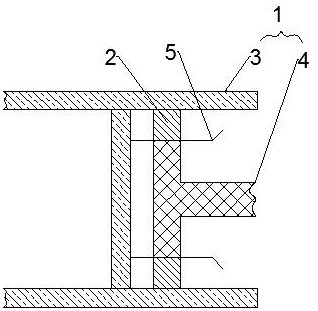

[0042] like figure 1 As shown, an intelligent knife switch system includes an isolating knife switch 1, a heat-sensitive element 2 and a monitoring device; the isolating knife switch 1 includes a static contact 3 and a moving contact 4; the static contact 3 is provided with an inner contact finger 5 , the thermosensitive element 2 is arranged between the static contact 3 and the inner contact finger 5; the monitoring device is arranged on the static contact 3; the monitoring device includes a power supply 6, a single-chip microcomputer module, a temperature sensor and a wireless module; the power supply 6 is connected with the single-chip microcomputer module respectively 1. The temperature sensor is electrically connected to the wireless module, and the single-chip microcomputer module is electrically connected to the temperature sensor and the wireless module respectively; the temperature sensor is in contact with the thermal element 2 .

[0043] The isolating knife switch 1...

Embodiment 2

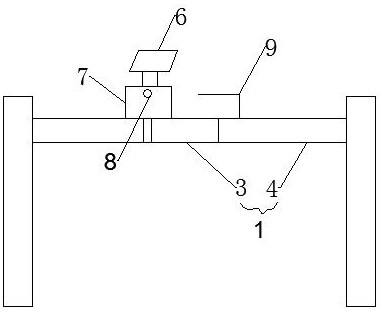

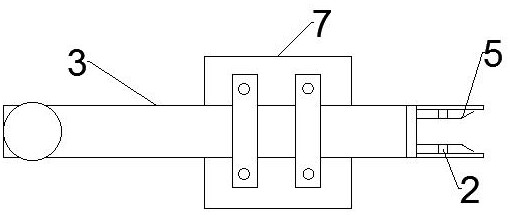

[0047] like figure 2 , image 3 and Figure 4 As shown, this embodiment relates to an intelligent knife switch system, and its structure is roughly the same as that of Embodiment 1. This embodiment is further optimized on the basis of Embodiment 1. The single-chip microcomputer module is electrically connected to a GPS module, and the GPS module and the wireless module electrical connection.

[0048] The isolation switch 1 is generally installed in the electric field, and there are a large number of isolation switches 1 in the electric field, so in order to facilitate the timely monitoring of the isolation switch 1 and the implementation of emergency measures, the single-chip microcomputer module is electrically connected to the GPS module, and the GPS module and the wireless module Electrical connection, through the setting of the GPS module, the position of the overheated isolation switch 1 can be accurately judged, which is convenient for the staff to find the correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com