Full-automatic header, larva moving and pulp digging all-in-one machine and method

A fully automatic, all-in-one machine technology, applied in the agricultural field, can solve the problems of affecting the quality of royal jelly, low pulp extraction efficiency, and large amount of manual intervention, so as to facilitate secondary processing, reduce manual intervention, and reduce pulp extraction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

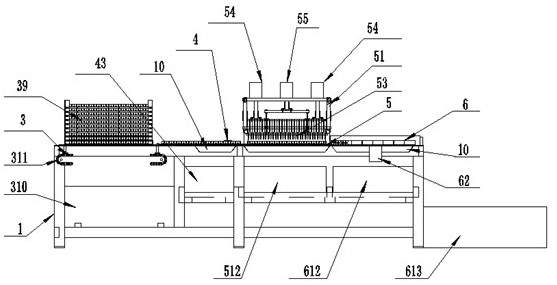

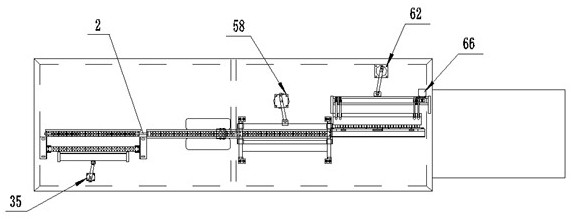

[0050] The first embodiment, such as Figure 1 to Figure 2 Shown: a full-automatic harvesting platform insect removal and dredging integrated machine and method, it includes: a frame 1 and a track 2 arranged on the frame 1, and the track 2 is sequentially provided with a The conveying mechanism 3 of the platform 11, the cap cutting mechanism 4 for cutting the honeycomb cover of the royal platform, the insect transfer mechanism 5 for the insect removal of the royal platform and the dredging mechanism 6 for dredging the royal platform.

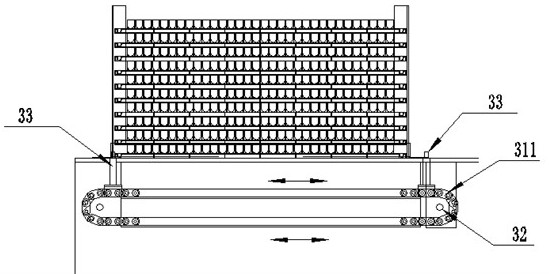

[0051] Such as Figure 3 to Figure 5 As shown: the conveying mechanism 3 includes a second motor 31 arranged on one side of the frame 1 and a first motor 35 on the other side of the frame 1, and the output of the second motor 31 A sprocket 32 is provided at the end, and the output end of the sprocket 32 is provided with a chain 311, and the chain 311 passes through the frame 1 and is symmetrically provided with a second push plate for pushi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com