Graphitized inner string and Acheson furnace dual-purpose mobile conductive equipment

A technology of Acheson furnace and conductive equipment, which is applied in the field of Acheson furnace dual-purpose mobile conductive equipment and graphitized inner string, which can solve problems such as temperature rise, large power effect, and aggravated temperature rise, and achieve high-efficiency conduction state, avoiding excessive temperature, and the effect of efficient heat exchange treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

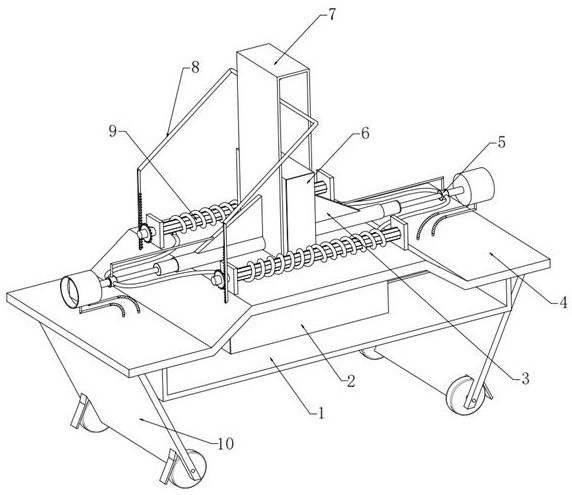

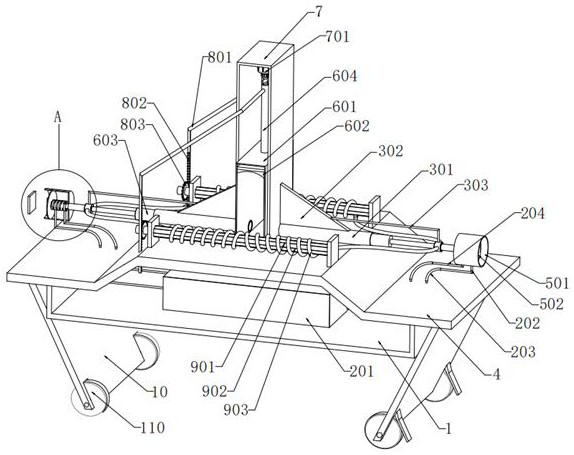

[0038] Such as Figure 1-Figure 6 As shown, the graphitized inner string and Acheson furnace dual-purpose mobile conductive equipment include a work table 4 with slopes on both sides, a hydraulic mechanism 6 and a drive assembly 7 are arranged on the work table 4, and the hydraulic mechanism 6 Both sides of the worktable 4 are provided with conductive components 5, the outer wall of the bottom of the worktable 4 is fixedly installed with a supporting plate 1, and the two conductive components 5 are connected with a cooling mechanism 2, and both sides of the worktable 4 are equipped with retractable The wire mechanism 9 and the hydraulic mechanism 6 include an oil tank body 601 fixedly installed on the outer wall of the top of the worktable 4, and both sides of the oil tank body 601 are fixedly connected with a connected oil chamber cylinder 603, and the inner walls of the oil chamber cylinder 603 are all slidably connected. There is a moving piston rod 606, and the conductive ...

Embodiment 2

[0052]Based on the graphitized inner string and Acheson furnace dual-purpose mobile conductive equipment provided in the first embodiment of the application, the second embodiment of the application proposes another graphitized inner string and Acheson furnace dual-purpose mobile conductive equipment . The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0053] The second embodiment of the present invention will be further described below in conjunction with the drawings and implementation methods.

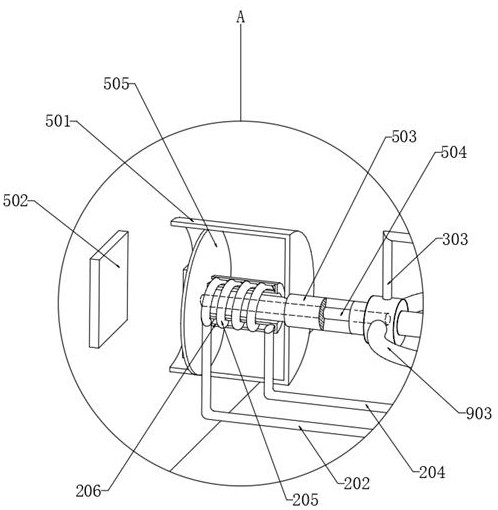

[0054] Such as Figure 7-Figure 9 As shown, in the second embodiment, both sides of the threaded sleeve 604 are provided with guide wheels 14 that are slidably connected to the mounting bracket, and the ends of the dustproof sleeve 501 are slidably connected to a movable end 506, and the movable end 506 is connected to the anti-dust sleeve. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com