Liquid-slag separation device for paint spraying wastewater

A technology for separation of liquid and slag and waste water, which is used in grease/oily substance/float removal devices, water aeration, water/sewage treatment, etc. Extraction and other problems to achieve the effect of reducing energy consumption, reducing cost and difficulty, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

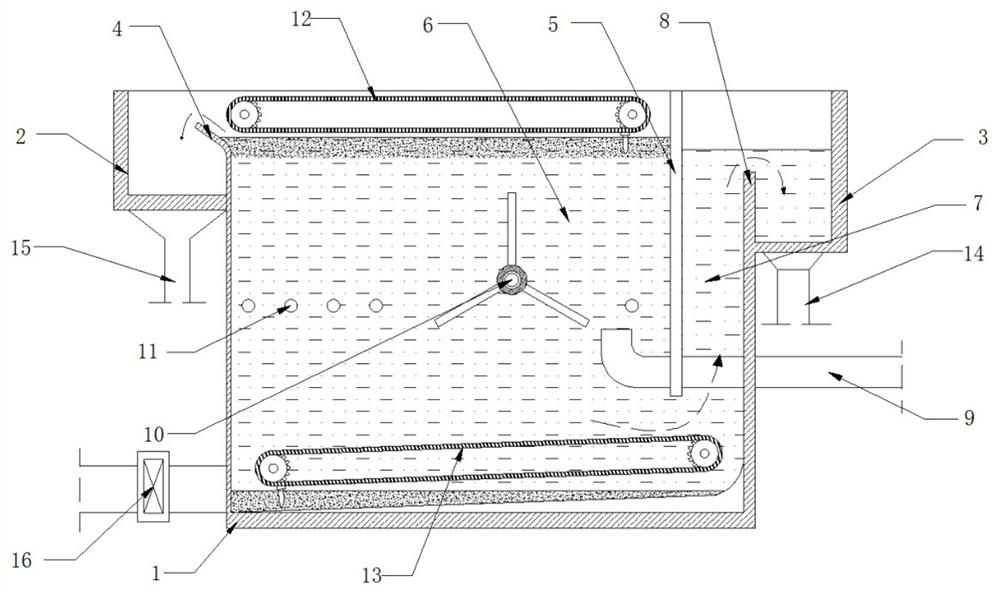

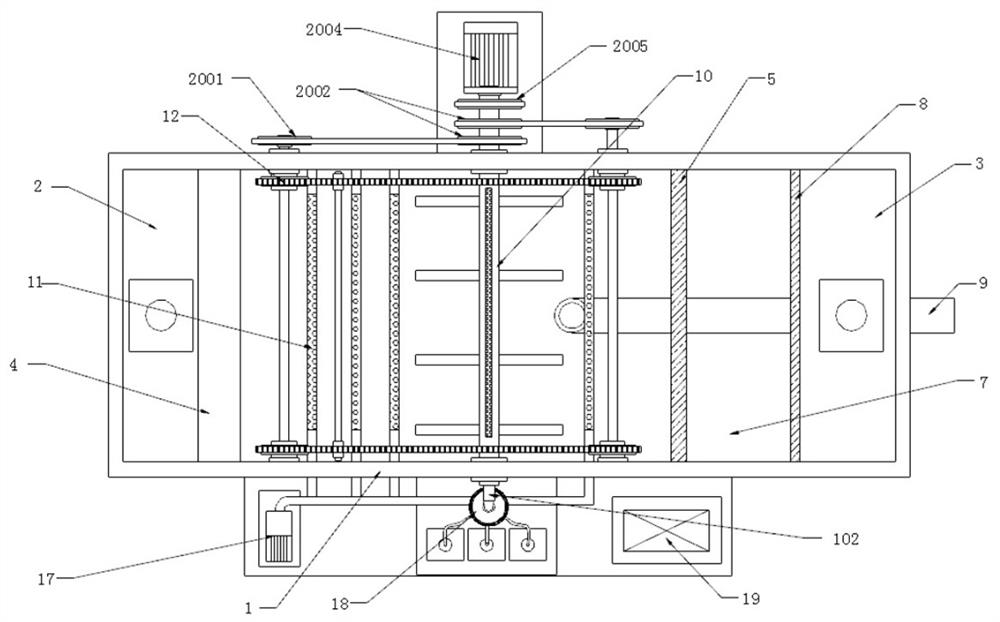

[0037] refer to Figure 1-2, a liquid slag separation device for paint spraying wastewater, comprising a device box 1, one end of the device box 1 is provided with a sewage tank 2, the other end is provided with a drainage box 3, and the end of the device box 1 close to the drainage box 3 A partition 5 is fixedly arranged, and a drainage gap is reserved between the bottom of the partition 5 and the bottom of the device box 1. The side of the partition 5 close to the drainage tank 3 forms a drainage channel 7, and the other side forms a reaction pool 6. A baffle 8 is arranged between the drainage channel 7 and the drainage box 3, and an arc-shaped plate 4 is arranged between the reaction pool 6 and the sewage box 2;

[0038] refer to figure 1 , 2 And 5, the device box 1 is located at the position below the drainage tank 3 and is equipped with a paint waste water pipe 9 extending to the inner cavity of the reaction tank 6. In the reaction tank 6, a mixing mechanism 10 is insta...

Embodiment 2

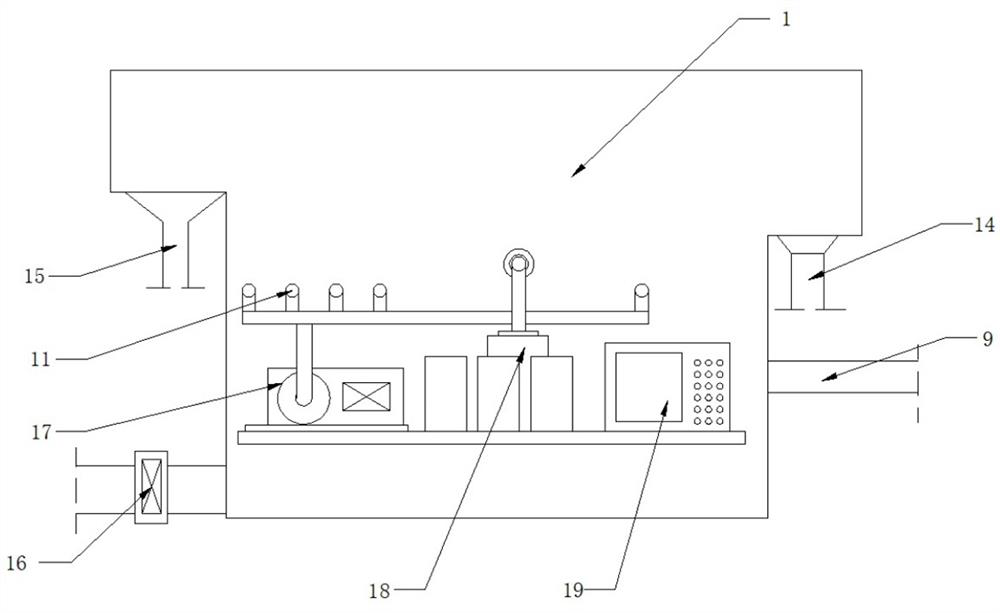

[0052] refer to Figure 7-10 The difference between this embodiment and Embodiment 1 is that the structure of the mixing mechanism 10 and the driving system 20 is different. In this embodiment, the mixing mechanism 10 is a floating structure, which includes a floating plate 106, a mixing paddle 113 and a linkage mechanism. The plate 106 is arranged in the reaction tank 6 and the two ends of the floating plate 106 are respectively provided with limit sliders 112, and the inner walls of both sides of the reaction tank 6 are longitudinally provided with limit chutes 21 matching the limit sliders 112, The limit slider 112 is slidably installed in the limit chute 21, and one end of the floating plate 106 is provided with a slide bar 107 along its width direction, and the slide bar 107 is provided with a movable groove 108 along its length direction, and the linkage mechanism includes a rotating shaft 111, Connecting rod 110 and rotating slider 109, rotating shaft 111 is installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com