Rectification dehydration equipment for hydrogen bromide electron gas

A dehydration equipment, electronic gas technology, applied in the direction of hydrogen bromide, bromine/hydrogen bromide, fractionation, etc., can solve the problems that the staff are easy to touch the bottle, shorten the life of the adsorbent, remove other gases, etc., to improve dehydration Efficiency, rational distribution of functions, and the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

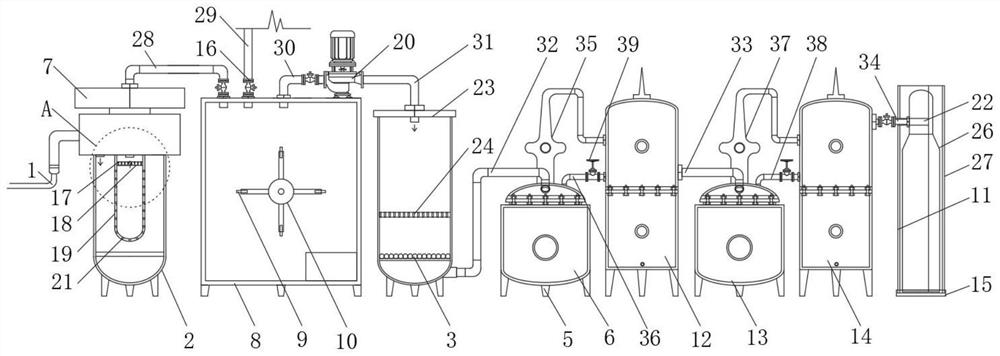

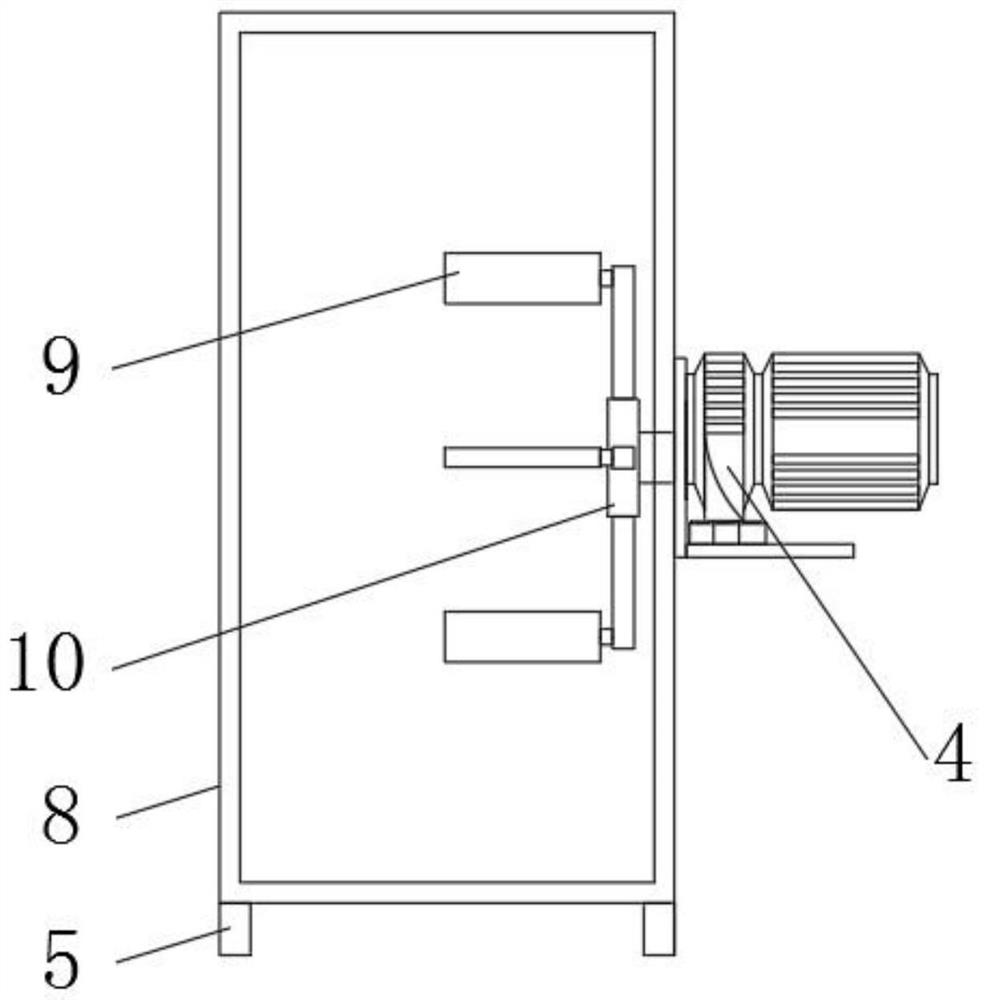

[0039] Such as Figure 1 to Figure 7 As shown, the present invention includes a dedusting mechanism, a stirring mechanism, a filtering mechanism, a rectifying mechanism and a protection mechanism connected in sequence, one side of the dedusting mechanism is connected to the first pipeline 1, and the other side of the dedusting mechanism is connected through the second pipeline 28 A stirring mechanism, the stirring mechanism is connected with the third pipeline 29, the stirring mechanism is connected with the conveying mechanism through the fourth pipeline 30, the conveying mechanism is connected with the filter mechanism through the fifth pipeline 31, and the filter mechanism is connected with the fine filter mechanism through the sixth pipeline. Distillation mechanism, the rectification mechanism is connected to the protection mechanism through the eighth pipeline 34, the protection mechanism is installed on the base 15, and the dust removal mechanism, the stirring mechanism, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com