Microfluidic chip for biological chemiluminescence detection and manufacturing method thereof

A microfluidic chip and luminescence detection technology, which is applied in the field of biochemical detection, can solve the problems of insufficient use of scattered light, failure to reach the maximum luminous intensity, and single flow path structure, so as to improve the efficiency of light detection and reduce the loss of scattered light , the effect of simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

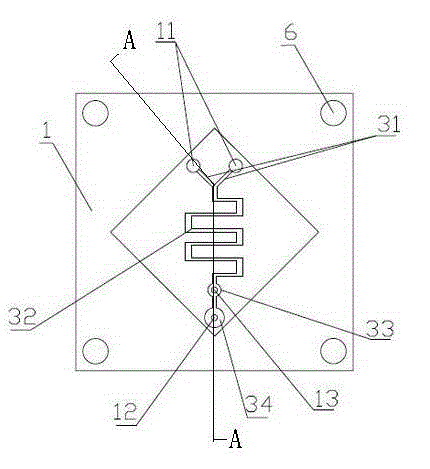

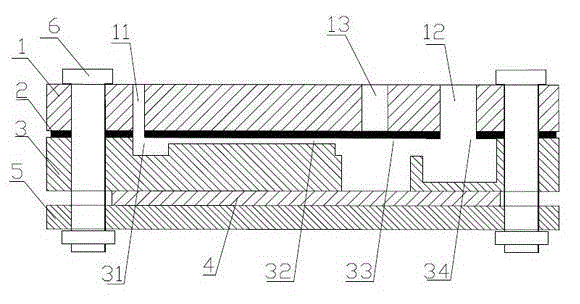

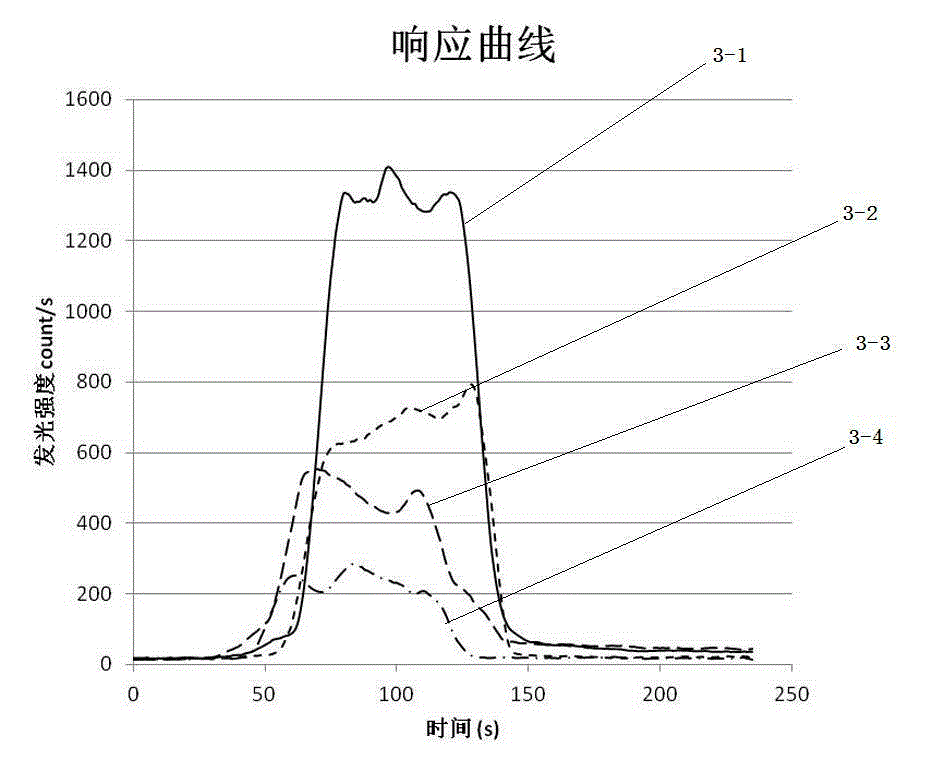

[0031] Such as figure 1 As shown, a microfluidic chip for biochemiluminescence detection, the chip includes an interface layer 1, a light-transmitting layer 2, a channel layer 3, a light-reflecting layer 4 and a fixed layer 5 arranged in sequence from top to bottom, each layer They are bonded together up and down by adhesives and fixed by four sets of fasteners 6. The interface layer 1 is a PMMA material substrate, the thickness of the interface layer 1 is 4mm, and the interface layer 1 is provided with two inlets with a diameter of 1mm. Liquid hole 11, a liquid outlet hole 12 with a diameter of 1.5 mm, an optical fiber connection hole 13 with a diameter of 2.25 mm, the channel layer 3 adopts a PMMA material substrate with a thickness of 3 mm, and the channel layer 3 is provided with two successively connected inlet holes. Liquid flow channel 31, a micro-mixer 32, a detection pool 33, and a waste liquid buffer pool 34, each channel has a width of 2 mm and a depth of 1.5 mm; th...

Embodiment 2

[0038] exist Figure 4 In the shown embodiment, a microfluidic chip for biochemiluminescent detection, the chip includes an interface layer 1, a light-transmitting layer 2, a channel layer 3, a light-reflecting layer 4 and a fixed layer arranged in sequence from top to bottom 5. The layers are bonded together up and down by adhesive and fixed by four sets of fasteners 6. The interface layer 1 is a PMMA substrate, the thickness of the interface layer 1 is 3.5mm, and the interface layer 1 is provided with 3 A liquid inlet hole 11 with a diameter of 1.5mm, a liquid outlet hole 12 with a diameter of 2mm, and an optical fiber connection hole 13 with a diameter of 1.5mm, the channel layer 3 adopts a PMMA material substrate with a thickness of 2.5mm, and the channel layer 3 is provided with Three liquid inlet flow channels 31, a micro-mixer 32, a detection tank 33, and a waste liquid buffer tank 34 are sequentially connected, each channel has a width of 1 mm and a depth of 1 mm; the ...

Embodiment 3

[0045] exist Figure 5In the embodiment, a microfluidic chip for biochemiluminescence detection, the chip includes an interface layer 1, a light-transmitting layer 2, a channel layer 3, a light-reflecting layer 4 and a fixed layer 5 arranged in sequence from top to bottom, each The layers are bonded together up and down by adhesive and fixed by four sets of fasteners 6. The interface layer 1 is a PMMA material substrate. The thickness of the interface layer 1 is 4.5mm. The liquid inlet hole 11, a liquid outlet hole 12 with a diameter of 2.5mm, and an optical fiber connection hole 13 with a diameter of 5mm, the channel layer 3 adopts a PMMA material substrate with a thickness of 3.5mm, and the channel layer 3 is provided with 4 sequentially connected A liquid inlet flow channel 31, a micro-mixer 32, a detection pool 33, and a waste liquid buffer pool 34, each channel has a width of 1.5 mm and a depth of 2 mm; the length of the liquid inlet flow channel 31 is 10 mm, and the fron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com