Carbon fiber steam drafting system and control method thereof

A control method and carbon fiber technology, applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problem of high adverse effects of fibers, and achieve the effect of improving the effect of damp heat, less wool, and small changes in dry humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

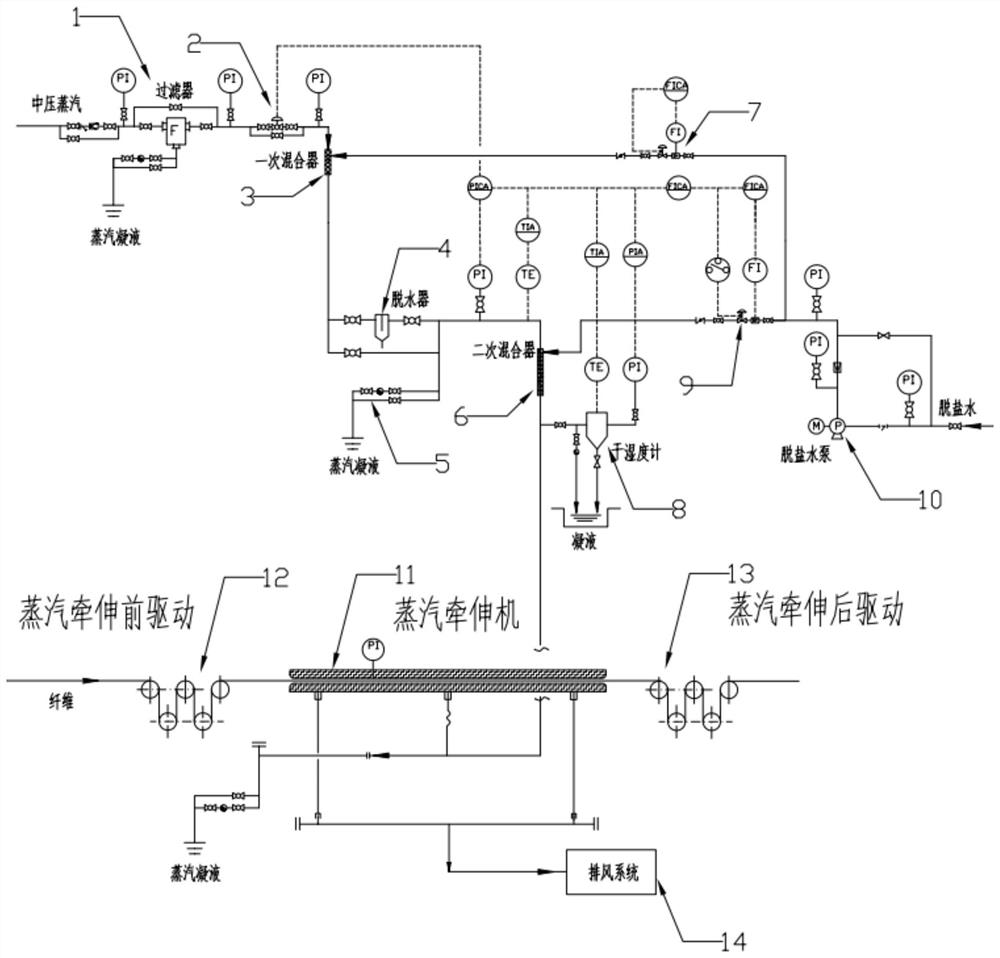

Method used

Image

Examples

Embodiment 1

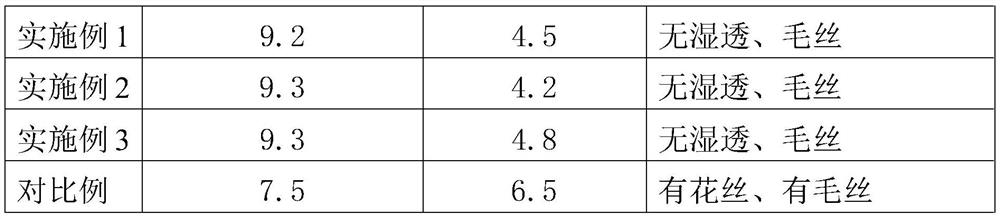

[0031] After the medium-pressure steam is decompressed to 0.5MPa, after passing through the two-stage mixer, dry hygrometer, and control system, when the dryness of the steam reaches 96.5%, the steam drafting ratio can reach 4.9 times, and the prepared PAN raw silk monofilament The strength can reach 9.2cn / dtex, the dispersion rate of the original silk strength is 4.5%, and the appearance of the fiber is not soaked or fuzzy.

Embodiment 2

[0033] After the medium-pressure steam is decompressed to 0.5MPa, after passing through the two-stage mixer, dry hygrometer, and control system, when the dryness of the steam reaches 97%, the steam drafting ratio can reach 5 times, and the prepared PAN raw filament monofilament The strength can reach 9.3cn / dtex, the dispersion rate of the original silk strength is 4.2%, and the appearance of the fiber is not soaked or fuzzy.

Embodiment 3

[0035] After the medium-pressure steam is decompressed to 0.5MPa, after passing through the two-stage mixer, dry hygrometer, and control system, when the dryness of the steam reaches 98%, the steam drafting ratio can reach 5.1 times, and the prepared PAN raw filament monofilament The strength can reach 9.3cn / dtex, the dispersion rate of the original silk strength is 4.8%, and the appearance of the fiber is not soaked or fuzzy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| linear density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com