Super-long steel pipe pile under marine deep mucky soil condition and construction method thereof

A technology of silty soil and steel pipe piles, which is applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of large pile sinking resistance, soil plugging effect, and difficult pile sinking, so as to improve the bending stiffness and reduce the Influence and reduce the effect of hoisting difficulties and safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

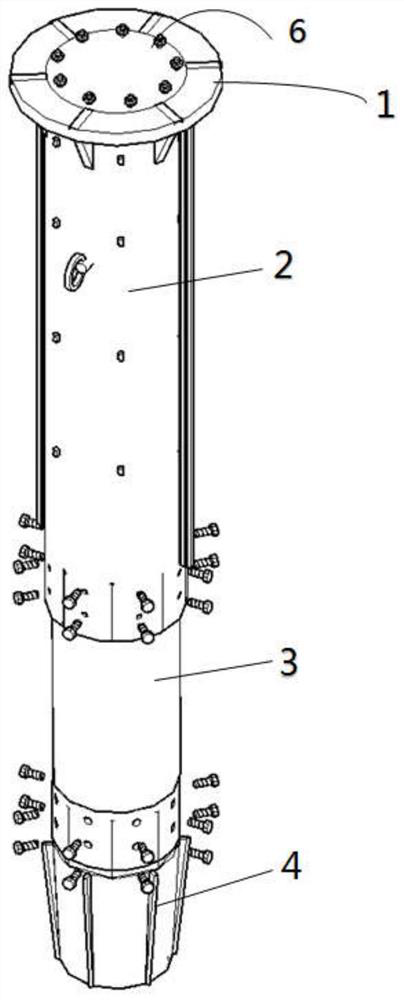

[0037] Such as figure 1 , the ultra-long steel pipe piles in marine facies deep muddy soil mainly include four parts: pile cap 1, pile body stiffening section 2, extension section 3 and pile tip 4, pile cap 1, pile body stiffening section 2, extension section 3 and the pile tip 4 are respectively fixedly connected with each other from top to bottom. The bottom diameter of the pile point 4 is slightly smaller than the top diameter.

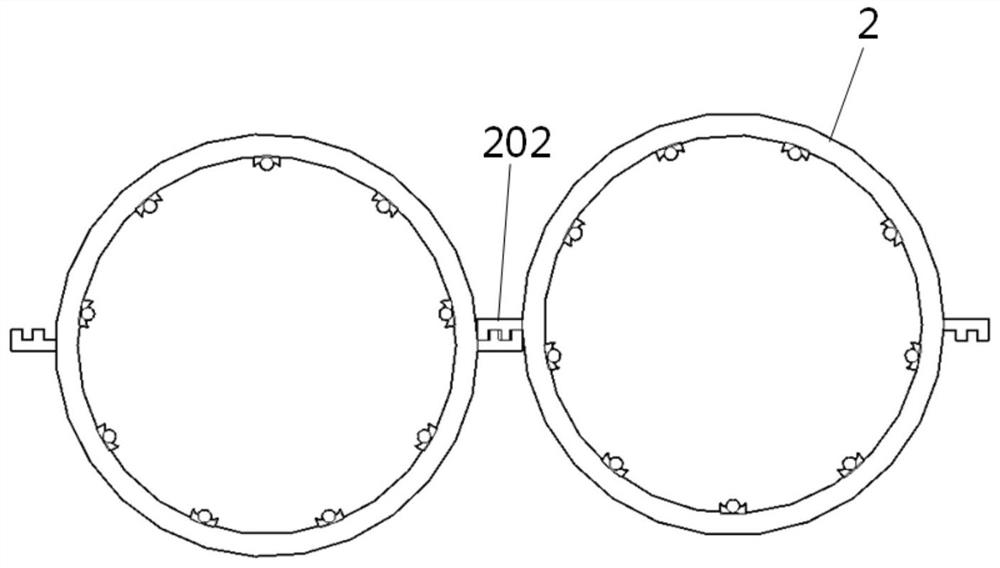

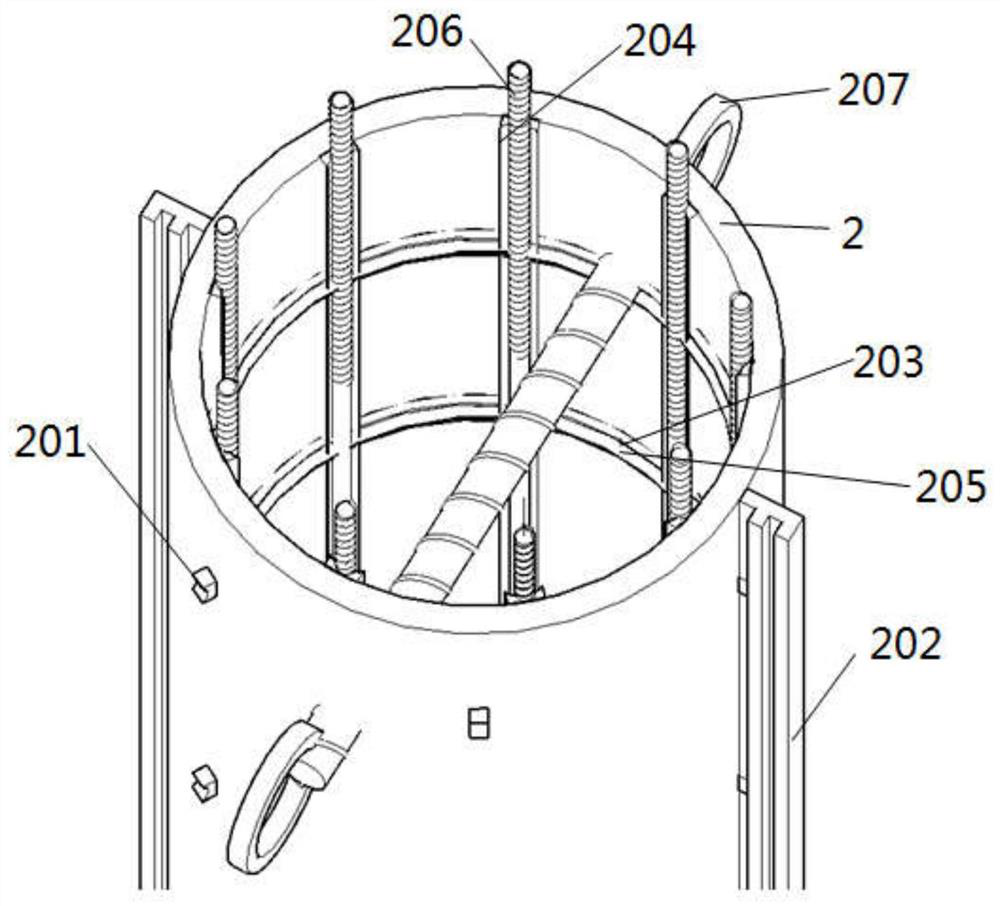

[0038] Such as Figure 2~3 , the outer two ends of the stiffening section are welded with "F"-shaped locks 202, and the opening and closing of the steel pipe piles overlap each other through the locks 202, extending horizontally, which improves the sealing of the steel pipe pile connection. The outer wall of the pile body stiffening section 2 is evenly welded with a number of steel bar positioning blocks 201 at intervals of 200mm along the longitudinal direction of the pile body. The outer side of the steel bar positioning blocks 201 is an open a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com