Vehicle-mounted hydrogen supply method and device for hydrogen-rich smelting of blast furnace or shaft furnace

A hydrogen supply and shaft furnace technology, which is applied in the field of vehicle-mounted hydrogen supply methods and equipment for hydrogen-rich smelting in blast furnaces or shaft furnaces, can solve the problems of high cost of hydrogen production plants, long construction period, unfavorable hydrogen supply, etc. The effect of hydrogen safety, low investment and construction cost, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to facilitate the understanding of the present invention, the present invention will be described in more detail below in conjunction with the accompanying drawings and specific embodiments.

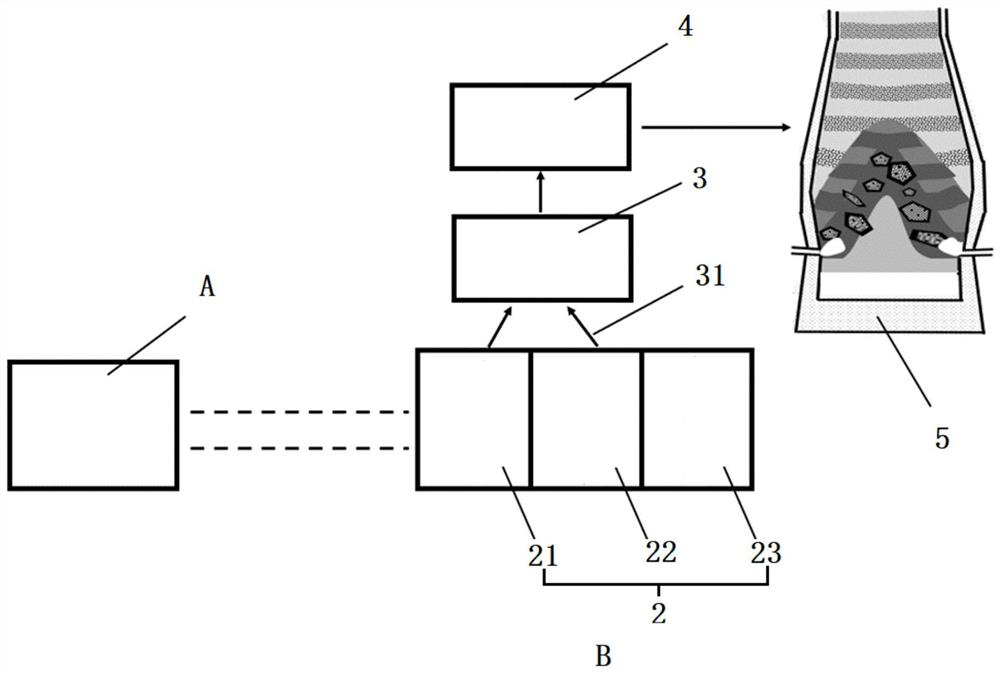

[0052] A vehicle-mounted hydrogen supply method for hydrogen-rich smelting in blast furnaces or shaft furnaces, the flow chart of which is as follows figure 1 shown, including the following steps:

[0053] S1. Set up multiple designated work parking spaces 2 at designated positions in or near iron and steel smelting plant B; the designated positions should be able to meet the shortest distance required for safe production of iron and steel smelting;

[0054] S2, according to the distance from the hydrogen supply station A to the designated working parking space 2, and the daily hydrogen demand of the iron and steel smelting plant B, calculate the number N1 of hydrogen transport devices 1 in transit and the number N1 that can normally supply hydrogen in the dedicated parki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com