A high temperature resistant device for powder metallurgy damping experiment

A technology of powder metallurgy and high temperature resistance, which is applied in the field of high temperature resistance devices for powder metallurgy damping experiments. It can solve the problems that the opening time of the window affects the internal experimental temperature, affects the measurement accuracy of the sensor, and it is difficult to ensure the accuracy of measurement data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

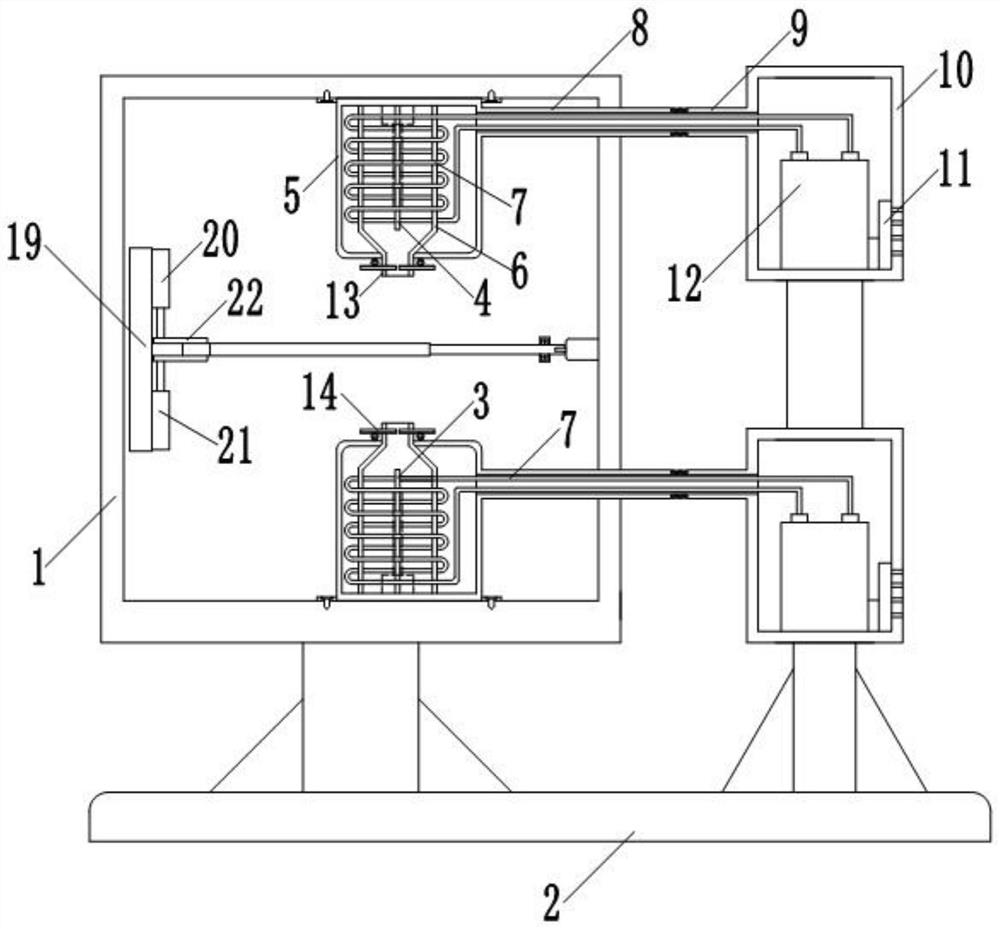

[0057] like figure 1As shown, the embodiment of the present invention provides a high temperature resistance device for powder metallurgy damping experiments, including a high temperature vacuum furnace 1, which is fixed on a base 2; a test piece fixing device, which is fixed in the middle of the high temperature vacuum furnace 1 for fixing the test piece Two cooling devices, one cooling device is fixed at the position opposite to the test piece above the high-temperature vacuum furnace 1, and the other cooling device is fixed at the position opposite to the test piece under the high-temperature vacuum furnace 1; Two switch assemblies, They are respectively fixed at the openings at the opposite ends of the two cooling devices and the test piece; the vibration generating device is fixed inside one of the cooling devices; the vibration part 3 of the vibration generating device passes through the switch assembly and is driven by contact with the test piece. The test piece vibrate...

Embodiment 2

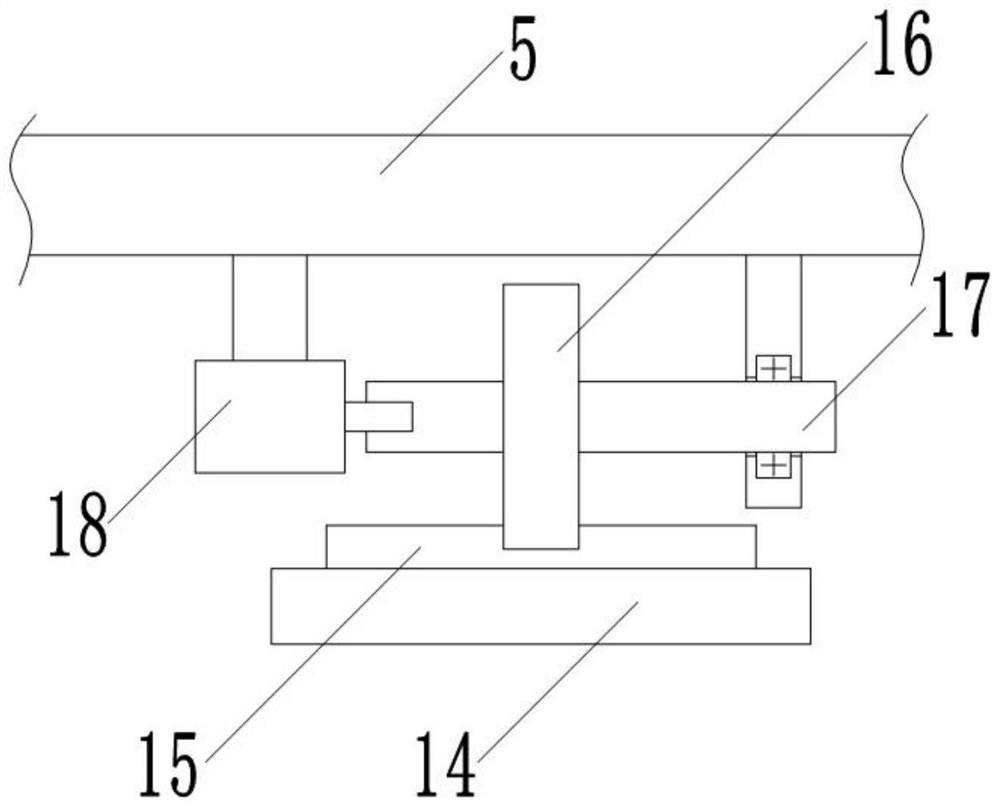

[0066] This embodiment is based on Embodiment 1. The specimen fixing device includes a cuboid 19, which is fixed on the lateral movement mechanism; a first electric push rod 20, whose outer casing is fixed on the cuboid 19; a second electric push rod 21, whose outer casing is fixed on the cuboid 19 The body is fixed on the cuboid 19, and the telescopic end of the second electric push rod 21 is relatively telescopic with the first electric push rod 20; two pressing plates 22 are respectively connected with the first electric push rod 20 and the second electric push rod 20. The telescopic ends of the electric push rod 21 are fixedly connected; wherein, the first electric push rod 20 and the second electric push rod 21 press the test piece from the upper and lower sides.

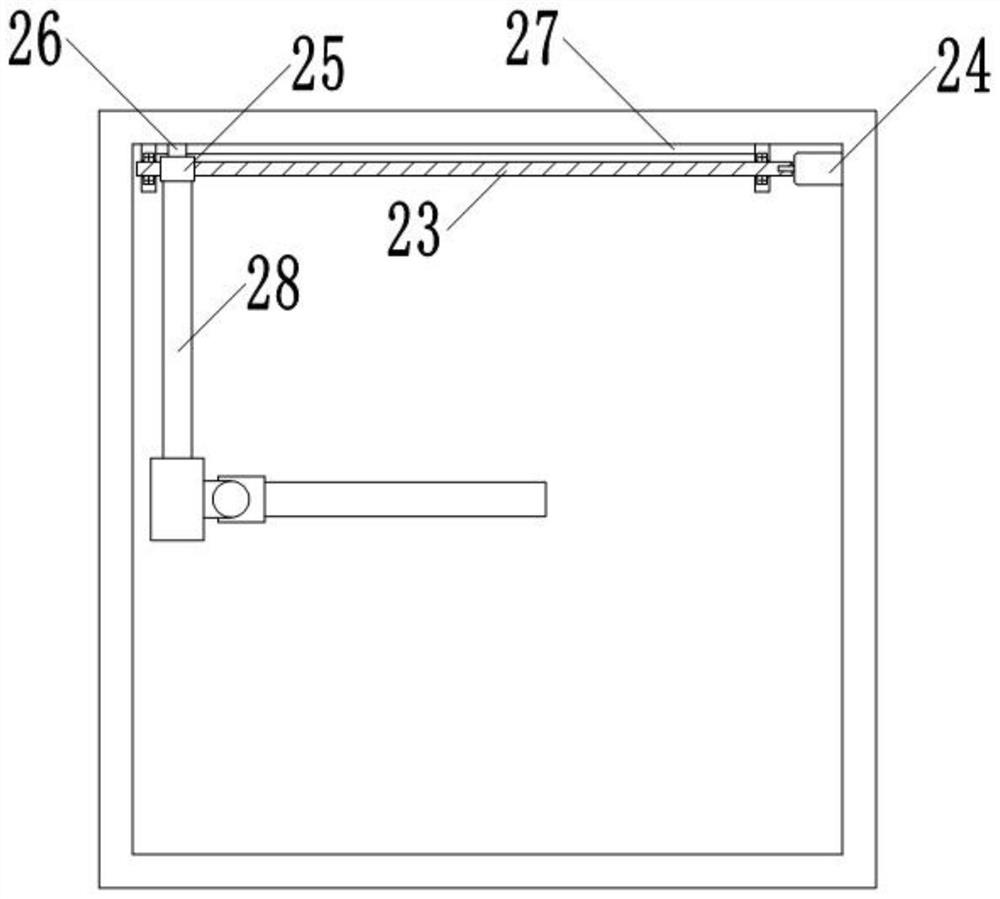

[0067] Further, the lateral movement mechanism includes a screw 23, the left and right ends of which are connected to the bearing seat fixed on the inner side wall of the high temperature vacuum furnace 1 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com