Building material detection system and method

A detection system and technology for building materials, applied in the direction of analyzing materials, applying stable tension/pressure to test the strength of materials, measuring devices, etc., can solve the problems of reducing labor intensity, high labor intensity, hidden safety hazards, etc., to reduce labor Strength, avoiding potential safety hazards, and avoiding the effects of lateral offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

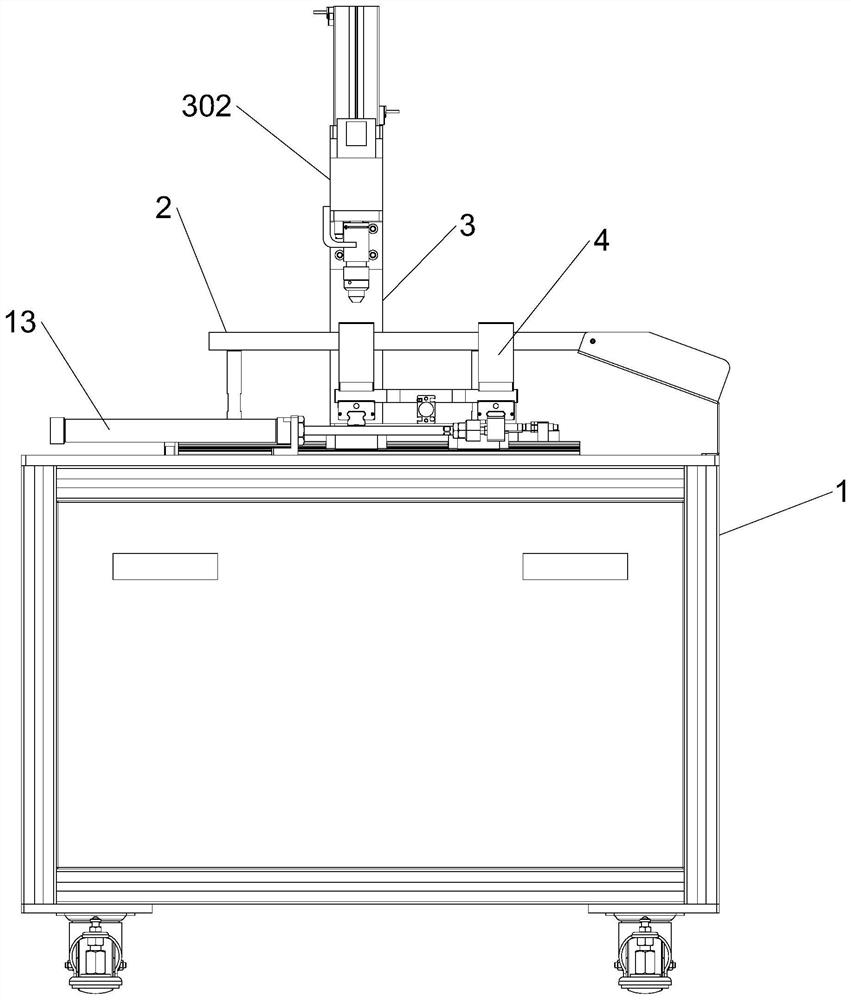

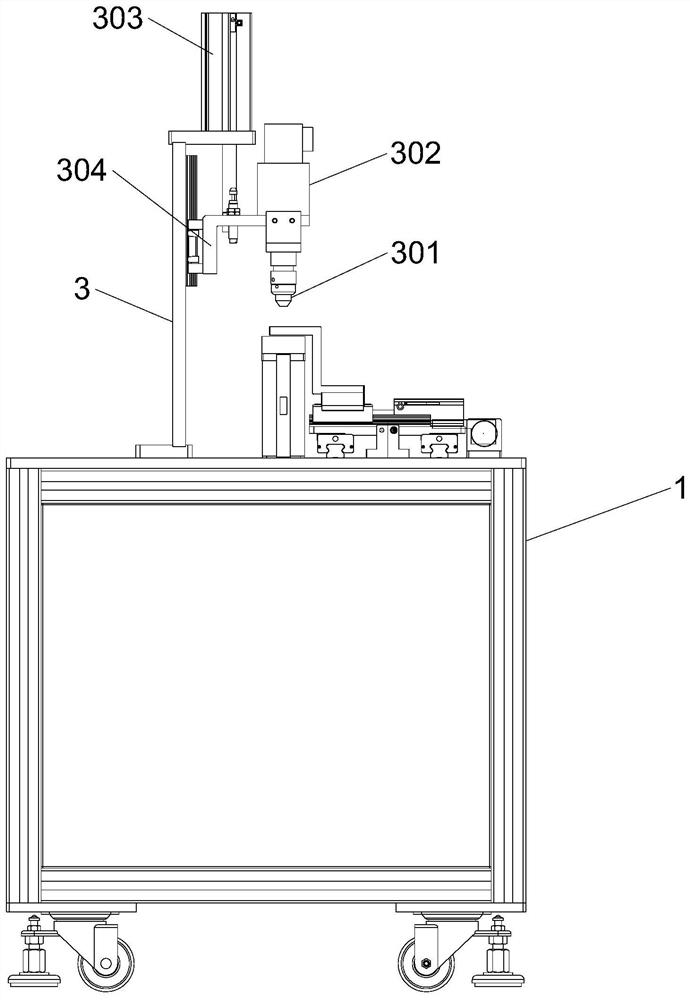

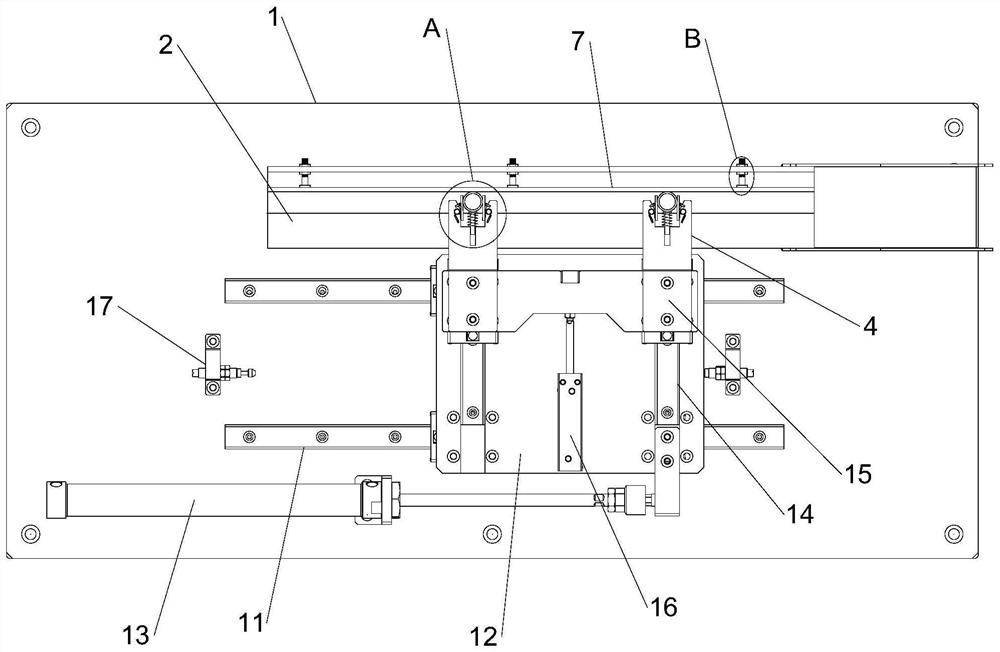

[0041] The detection system for building materials of the present invention comprises a placement platform 1, a workbench 2 is arranged above the placement platform 1, a support plate 3 is provided on the upper end of the placement platform 1, a detection air pump 302 is provided on the support plate 3, and a detection air pump 302 The lower end of the workbench 2 is provided with a detection probe 301 above the workbench 2. The lower end of the detection probe 301 is tapered, and the upper end of the workbench 2 is provided with a positioning groove 201. A vertically placed pipe 202 is arranged in the positioning groove 201. The workbench 2 The upper end is provided with a baffle plate 7 that can move along the relative positioning groove 201. The upper end of the workbench 2 is provided with a manipulator 4. The manipulator 4 is provided with an elastic holding assembly 5 for elastically holding the outer wall of the pipe material 202. The manipulator 4 and the baffle plate 7 ...

Embodiment 2

[0044] This embodiment is further optimized on the basis of Embodiment 1 as follows: the elastic holding assembly 5 includes two symmetrically arranged elastic holding units, and the elastic holding units include a holding plate 501, a positioning pin, a positioning cylinder 502, Positioning frame 503, positioning plate 506, torsion spring 505 and fixed pin 504; The side wall of manipulator 4 runs through and is provided with hold tight groove 401, and the two inwalls of hold tightly groove 401 are all provided with hold tight inclined-plane, between two hold tightly inclined-planes The distance between them increases gradually along the outward direction. The holding plate 501 is set in the holding groove 401. The positioning cylinder 502 is arranged on the holding plate 501 and is located on the side close to the holding slope. The positioning cylinder 502 runs through the positioning cylinder 502. , the two ends of the positioning cylinder 502 are connected to each other wit...

Embodiment 3

[0047] This embodiment is further optimized on the basis of Embodiment 1 as follows: the bottom wall of the holding groove 401 is also provided with a guide groove 6, a guide rod 601 is arranged in the guide groove 6, and a guide rod 601 is arranged on the upper end of the guide rod 601. The ejection plate 603 where the pipes 202 are in contact with each other, the guide rod 601 is covered with an ejection spring 602 , and the ejection spring 602 is located between the ejection plate 603 and the bottom wall of the holding groove 401 .

[0048] After adopting the above technical solution: by setting the guide rod 601 and the guide groove 6, during the process of tightening the pipe 202, the ejection spring 602 is further compressed. When the pipe 202 needs to be unloaded after the inspection is completed, the manipulator 4 drives the pipeline to slide within the positioning, and the baffle 7 is always in contact with the pipe 202 during the movement; The hindrance effect of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com