Method for designing mix proportion of high-modulus recycled asphalt mixture

A mix ratio design, recycled asphalt technology, applied in the field of road petroleum asphalt, can solve the problems of low recycling rate of construction waste, rutting disease, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

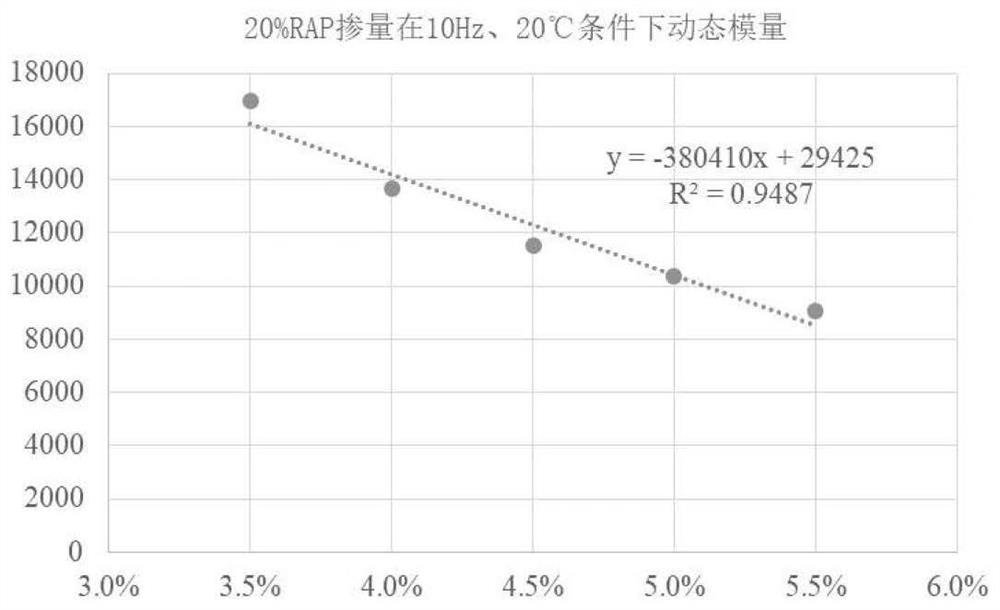

[0022] Example 1: The milling material (0-5mm and 5-10mm) is obtained by crushing and screening the old road reconstruction, and the new aggregate adopts 10-20mm, 5-10mm limestone, 0-5mm machine-made sand and mineral powder. The gradation form is AC-20. The amount of milling material is 20%, and the passing rate of each sieve hole is shown in Table 1. It is determined from 3.5%, 4.0%, 4.5%, 5.0% and 5.5%, the traditional best oil-stone ratio OAC = 4.19%, 10Hz dynamic model Quantitative fitting results such as figure 1 As shown, the OAC is calculated from this modulus It is 3.97%, which is 0.22% lower than the traditional optimal oil-stone ratio, and the amount of oil in the mixture is reduced within a reasonable range. On the basis of adding milling material, the modulus of the mixture is further improved, which is beneficial to prevent the formation of ruts.

example 2

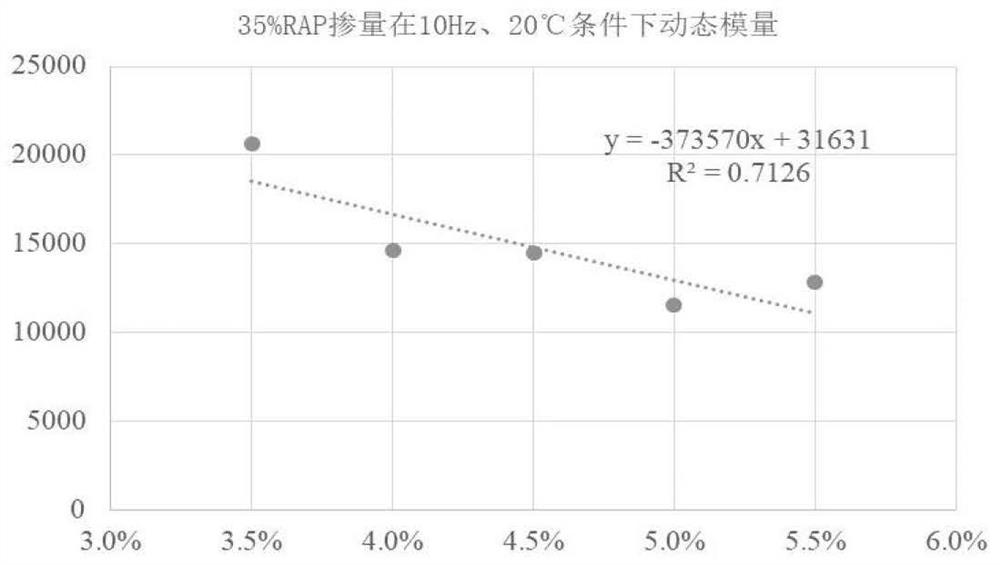

[0023] Example 2: The milling material (0-5mm and 5-10mm) is obtained by crushing and screening the old road reconstruction, and the new aggregate adopts 10-20mm, 5-10mm limestone, 0-5mm machine-made sand and mineral powder. The gradation form is AC-20. The amount of milling material is 35%, and the passing rate of each sieve hole is shown in Table 2. It is determined from 3.5%, 4.0%, 4.5%, 5.0% and 5.5% that the traditional best oil-stone ratio OAC=4.06%, and the dynamic modulus The fitting result is as figure 2 As shown, the OAC is calculated from this modulus It is 3.79%, which is 0.27% lower than the traditional optimal oil-stone ratio, and the amount of oil in the mixture is reduced within a reasonable range. On the basis of adding milling material, the modulus of the mixture is further improved, which is beneficial to prevent the formation of ruts.

example 3

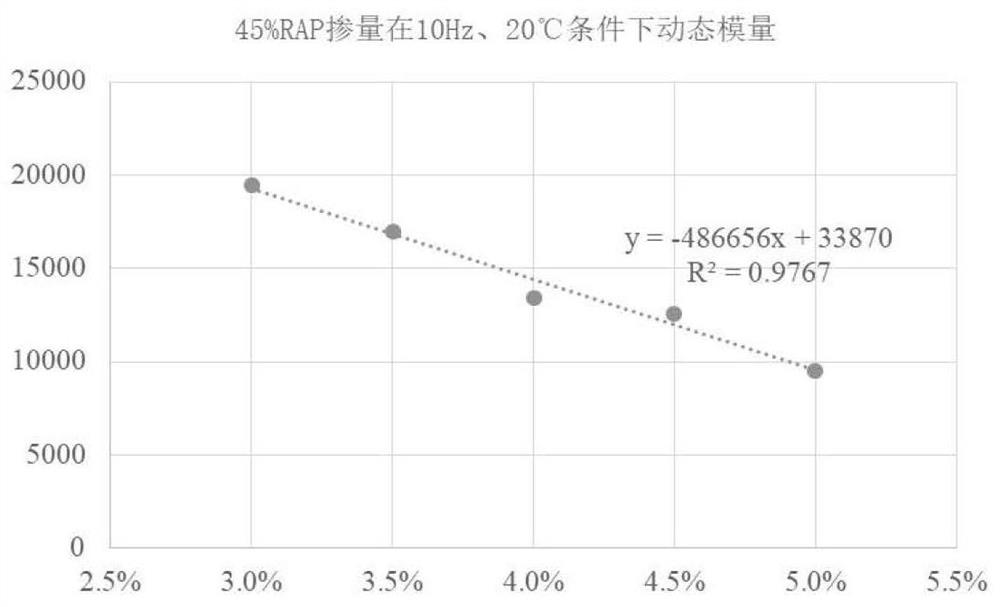

[0024] Example 3: The milling material (0-5mm and 5-10mm) is obtained by crushing and screening the old road reconstruction, and the new aggregate adopts 10-20mm, 5-10mm limestone, 0-5mm machine-made sand and mineral powder. The gradation form is AC-20. The amount of milling material is 50%, and the passing rate of each sieve hole is shown in Table 3. It is determined from 3.0%, 3.5%, 4.0%, 4.5% and 5.0% that the traditional best oil-stone ratio OAC=3.73%, and the dynamic modulus The fitting result is as image 3 As shown, the optimum asphalt-stone ratio considering the modulus is 3.54%, which is 0.19% lower than the traditional optimum asphalt-stone ratio, and the amount of oil in the mixture is reduced within a reasonable range. The material modulus is further improved, which is beneficial to prevent the formation of ruts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com