Rubber tapping machine capable of preventing rubber liquid from being dried

A rubber tapping machine and anti-drying technology, applied in agriculture, forestry, application, etc., can solve the problems of low latex flow, latex waste, and latex moisture reduction, and achieve the effects of reducing evaporation speed, avoiding latex drying, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

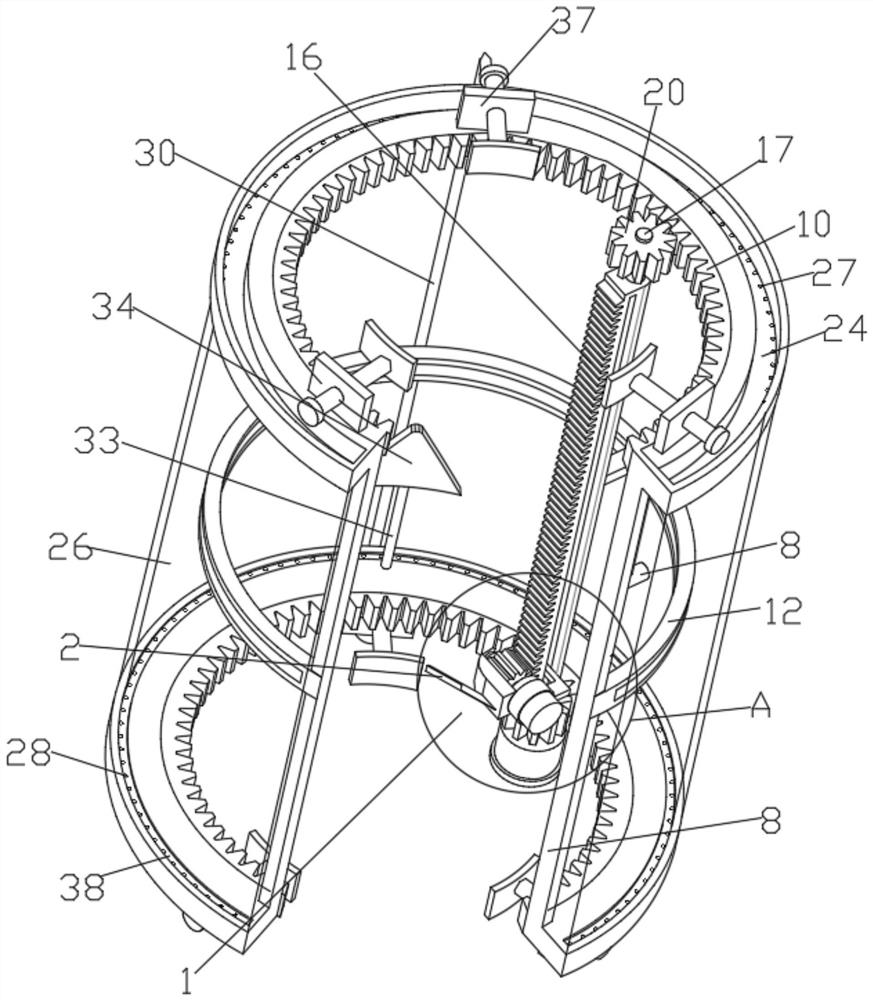

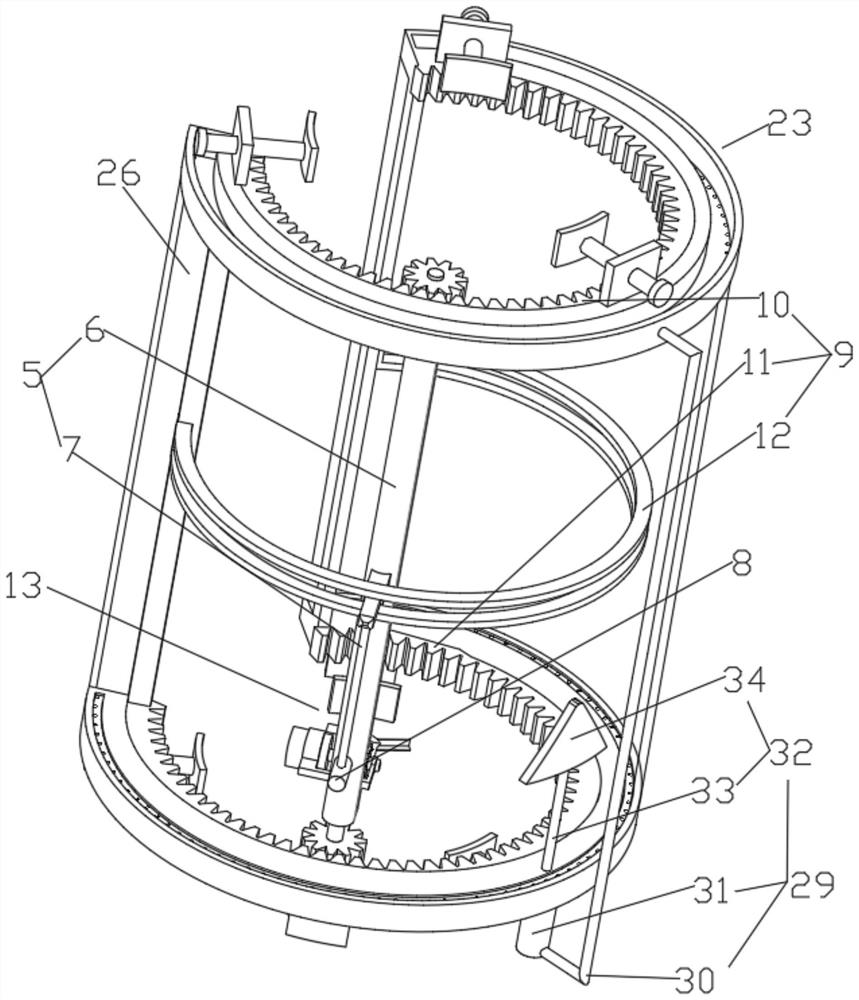

[0024] see Figure 1 to Figure 4 , a kind of rubber tapping machine that prevents glue from drying provided by the present invention includes a rubber tapping knife 1, a sliding frame 5, a guide rail set 9, a drive assembly 13 and an anti-drying device 23, and the guide rail set 9 is fixed to the rubber tree by a clamping assembly 37. On the trunk, play the effect that the rubber tapping machine is fixed on the rubber tree trunk, wherein the clamping assembly 37 is a prior art, no more details here, the sliding frame 5 is slidably connected with the guide rail group 9, and the rubber tapping knife 1 Installed on the sliding frame 5, it moves spirally around the rubber tree trunk along the guide rail group 9, the driving assembly 13 drives the rubber tapping knife 1 to spirally tap rubber along the rubber tree trunk, the anti-drying device 23 is connected to the guide rail group 9, The anti-drying device 23 can be fixed. The anti-drying assembly includes an upper water tank 24,...

Embodiment 2

[0032] see Figure 1 to Figure 3 The difference between this embodiment and Embodiment 1 is that the guide rail set 9 includes an upper arc rack 10, a lower arc rack 11 and a sliding guide rail 12, and the upper arc rack 10, the sliding guide rail 12 and the lower The arc racks 11 are sequentially connected by connecting rods. Through the cooperation of the upper arc rack 10, the lower arc rack 11 and the drive assembly 13, the rubber tapping knife 1 can be made to perform a spiral movement, and the sliding guide rail 12 plays the role of stabilizing the drive assembly 13, wherein the upper arc rack 10 and The opening side of the lower arc rack 11 can be hinged with a transparent windshield to further reduce the evaporation of latex moisture.

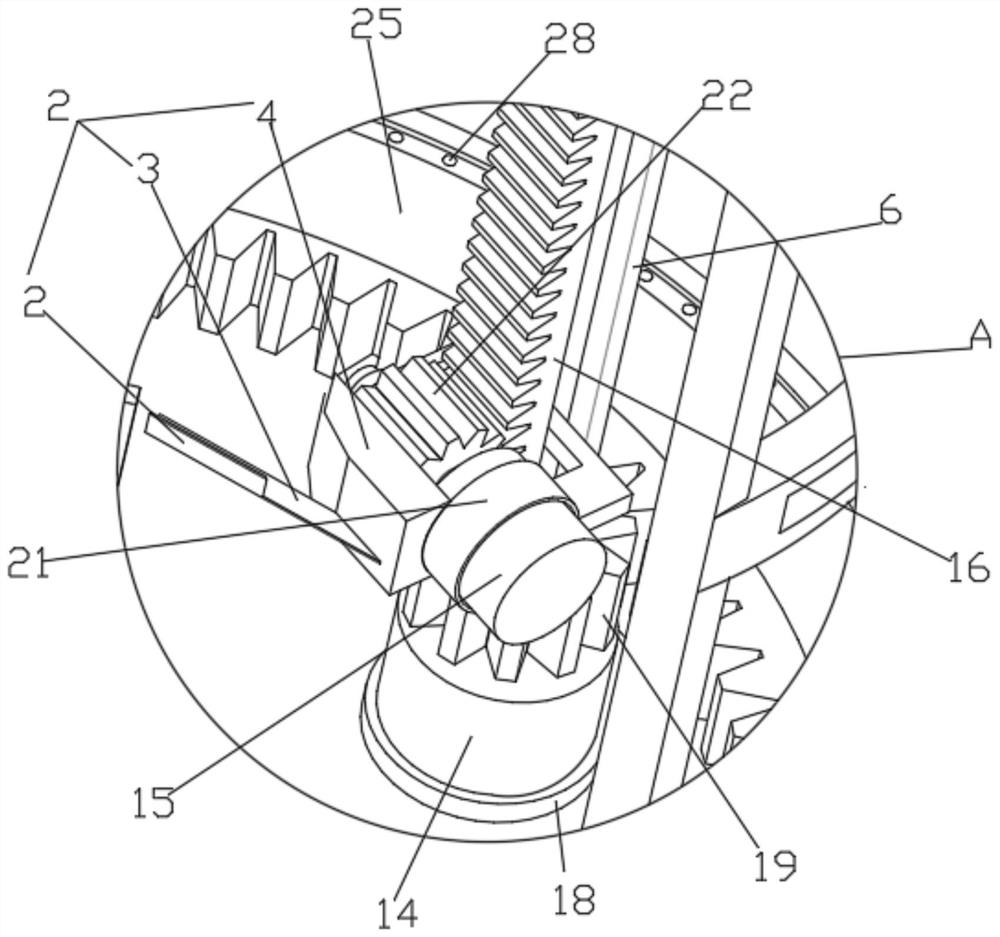

[0033] Specifically, the drive assembly 13 includes a first motor 14 , a second motor 15 , a rack 16 and a connecting shaft 17 , and the first motor 14 is slidably connected to the lower arc rack 11 through a first mount 18 , the outp...

Embodiment 3

[0035] see Figure 1 to Figure 2 The difference between this embodiment and Embodiment 1 is that the rubber tapping knife 1 includes an L-shaped knife 2, a connecting portion 3, an arc-shaped mounting seat 4 and a third motor, and the L-shaped knife 2 is connected to the connecting portion 3 , the connecting part 3 is rotatably connected to the arc-shaped mounting seat 4, the third motor is installed in the arc-shaped mounting seat 4, and the third motor is used to drive the L-shaped knife 2 to rotate. The L-shaped knife 2 is convenient to cut the bark of the trunk of the rubber tree, so that a latex flow groove is formed on the cutting opening of the trunk, which is convenient for the collection of latex. The L-shaped knife 2 is connected with the arc mounting seat 4 through the connecting part 3, and the arc mounting seat The front end of 4 is in the shape of an arc, which is convenient for the cut rubber bark to fall from the connecting part 3 and the arc mounting seat 4 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com