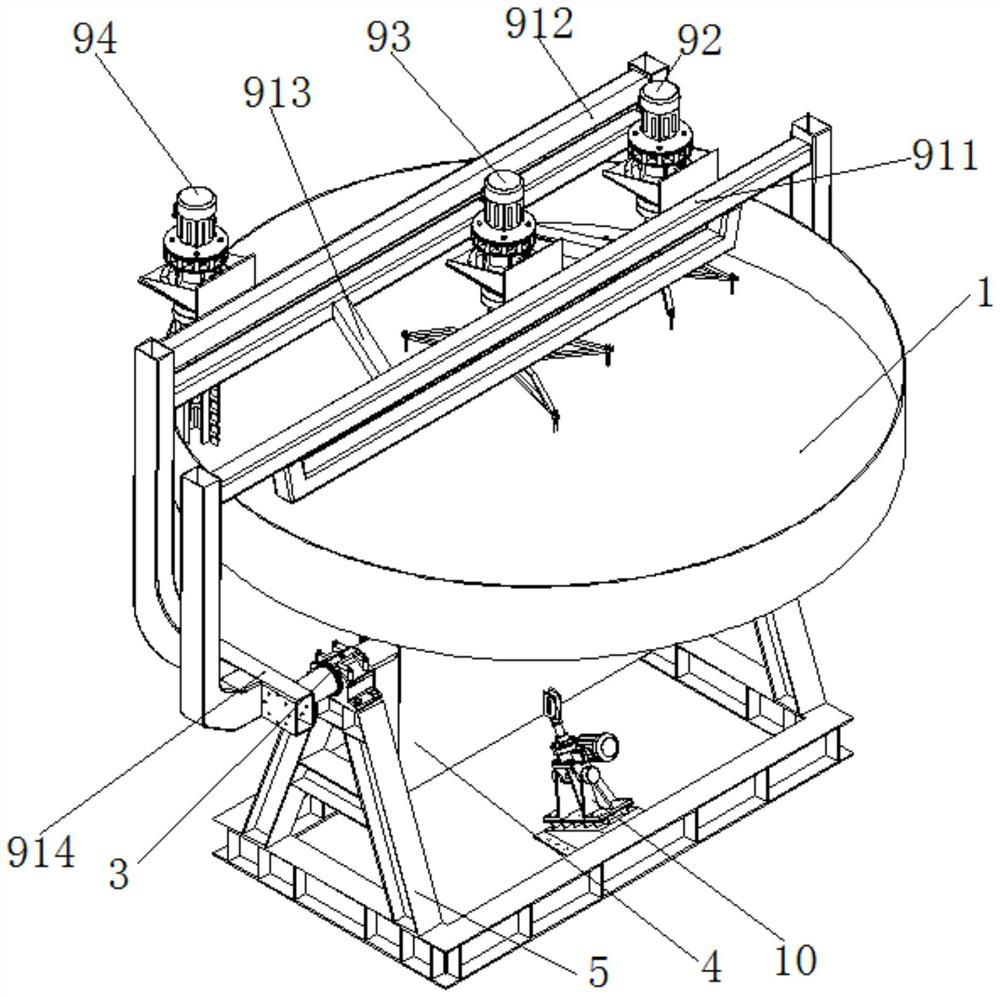

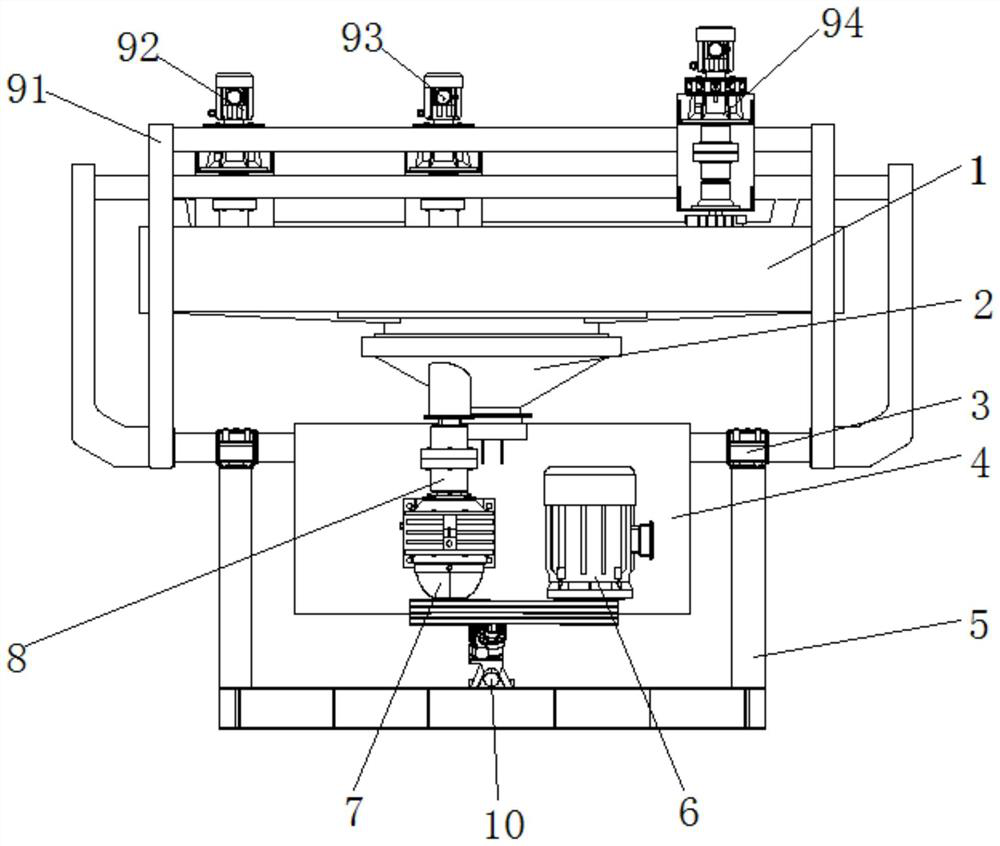

Multi-rod mixing device and method for viscous materials

A technology for mixing devices and materials, applied in mixers with rotating containers, mixers, chemical instruments and methods, etc., can solve the problems of uneven mixing, low efficiency, unclean discharge, etc., to improve mixing efficiency, contact Small area, the effect of preventing unclean unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

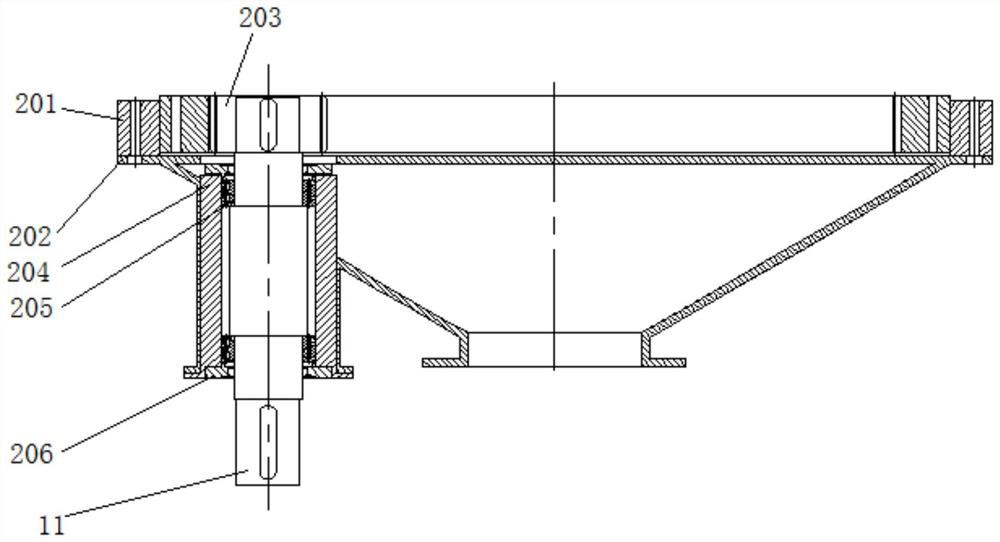

Method used

Image

Examples

Embodiment 1

[0054]Embodiment 1: The material selected in this embodiment is papermaking sludge. When the equipment is in operation, the rotating speed of the rotating disk 1 is 8r / min, and the rotation speed of a plurality of rotating rods 927 on the first stirring mechanism 92 and the second stirring mechanism 93 is is 1m / s, the rotation speed of the scraper 946 is 30r / min, and the papermaking sludge flows to the first stirring mechanism 92 and the second stirring mechanism 93 driven by the rotating motion of the rotating disk 1, where the first stirring mechanism 02 and the second stirring mechanism The second stirring mechanism 93 is stirred and mixed by a plurality of rotating rods 927, and then continues to circulate under the drive of the rotating disk 1, and stirs and mixes again when the papermaking sludge is dispersed and has not been bonded into a block, and it goes round and round to realize the papermaking sludge. The mixing effect is uniform, and the mixing efficiency is impro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com