Carbon fiber wound gas cylinder and monitoring method of health state of gas cylinder

A technology for winding gas cylinders and health status, which is applied in the field of monitoring carbon fiber winding gas cylinders and their health status. , small size, the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

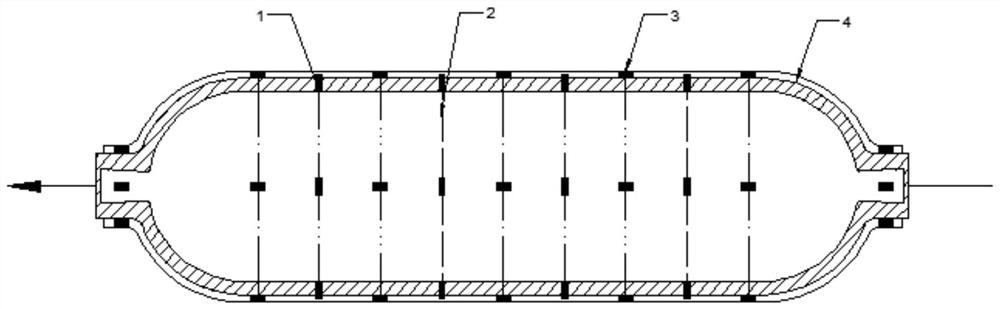

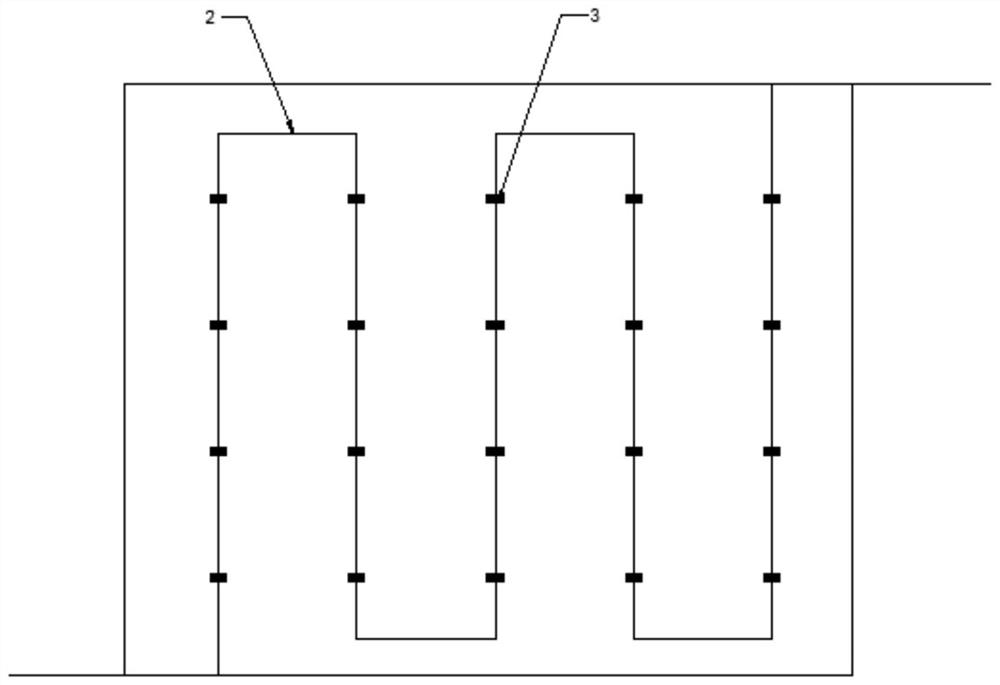

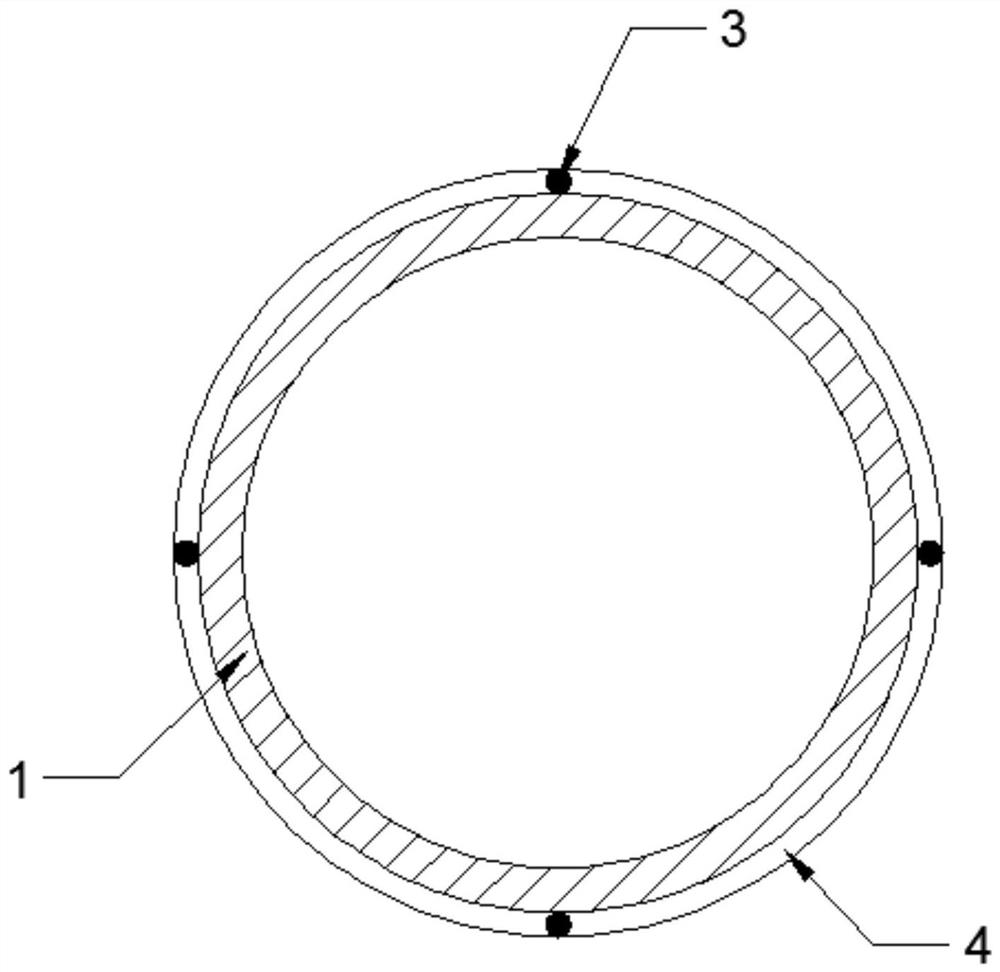

[0054] like Figure 1 - Figure 3 , The carbon fiber of the present invention provide a wound cylinder, comprising a cylinder body, the cylinder body 1 with an optical fiber 2 is wound uniformly with a number of four grid points 3, wherein the optical fiber 2 using four spirally wound fabric sticker or serpentine wound cloth paste, a number of grid points 3 are each arranged on the optical fiber 2, the optical fiber 2 is wound on either the cylinder body 1 to ensure a radial section on the gate location point 3 are laid with a four-point gate 3 , point 3 along the axial direction of the gate body cylinder 1 arranged in a straight line and the adjacent two gate four points the same axial distance between the 3 (grid points of optical fibers 2 bonded by the glue 3 of the cylinder liner, gas bottle occurs upon expansion, it will lead to the gate region stretching, whereby demodulated center wavelength of reflected light is changed, whereby there results a strain of the gate region). L-...

Embodiment 2

[0083] This embodiment differs from Embodiment 1 This embodiment is characterized in that the formula (4), a value of is 0.7, b is a value of 0.3. Values as follows:

[0084] Hoop stress and axial stress graph is obtained when the test cylinder by normal operation, such as Figure 4 , According to the hoop stress and axial stress can be seen the graph, the peripheral cylindrical portion of the cylinder to stress axial stress ratio of about 7: 3, and thus taking a is 0.7, b is 0.3, the overall volume to obtain the coefficient of variation :

[0085] K 1 = 0.7x 1 + 0.3y 1 ,

[0086] α, β, γ, δ value of four coefficients:

[0087] α = 0.7m,

[0088] β = 0.3m,

[0089] γ = 0.7 (1-m),

[0090] δ = 0.3 (1-m);

[0091] K possible values between (0,1), according to a fatigue test cylinders, to obtain a graph showing the relationship between the K value and the number of fatigue tests, such as Figure 5 Shown to 10000,7500,3000 dividing point can be obtained as evaluation rules:

[0092]...

Embodiment 3

[0094] Example Example of the present embodiment that the difference between the two, four spiral-wound optical fiber cloth paste, such as Image 6 , The optical fiber and the cylinder body 2 to the circumferential angle of [theta] 1, the cylinder circumferential elongation of the gate region (grid point) is Δεcosθ, axial elongation of the cylinder of the gate region is Δεsinθ.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com