Collecting structure of battery and battery

A battery and current collector technology, applied in the direction of electrode carrier/current collector, etc., can solve the problems of low current conduction capacity, increased battery internal resistance, large internal resistance, etc., and achieve improved rate performance, high energy density, and heat generation rate. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

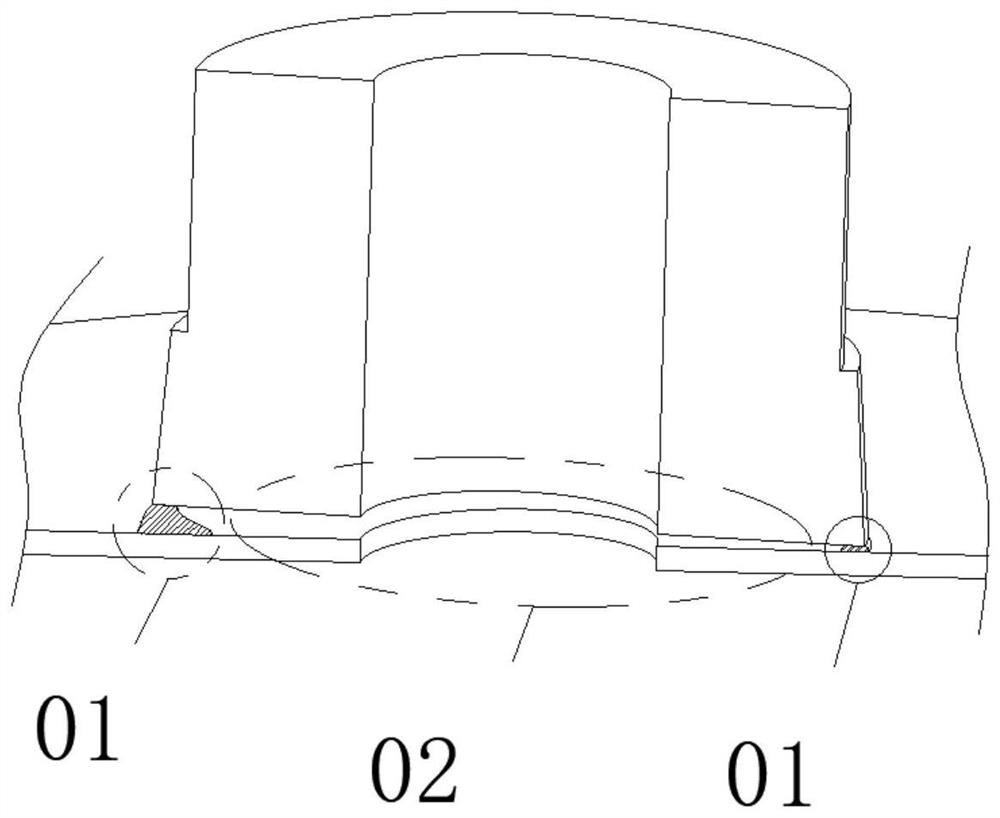

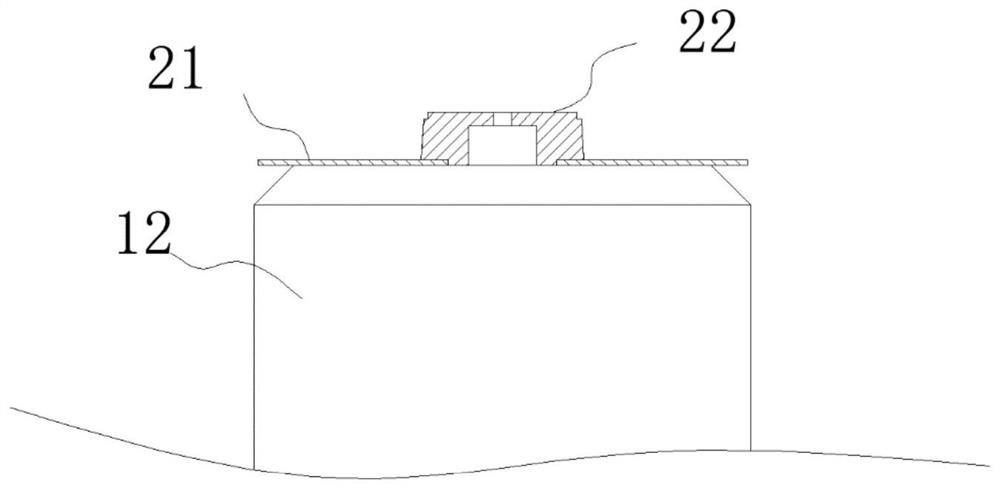

[0044] refer to Figure 3-Figure 4 The embodiment of the present invention provides a current collecting structure of a battery. The battery includes a battery cell 12. The current collecting structure includes a current collecting plate 21 and a current collecting post 22. One end face of the current collecting plate 21 is welded to an electrode end face of the battery cell 12. , the other end face of the collecting plate 21 is welded with the collecting column 22;

[0045] The current collecting post 22 includes a soldering pad 221 and an annular boss 222 formed on the soldering pad 221. A through hole 211 matching the annular boss 222 is opened on the collector disc 21, and the protrusion height of the annular boss 222 is the same as that of the through hole. The holes 211 have the same depth, and the annular boss 222 is welded and fixed to the collector plate 21 at the through hole 211 .

[0046] Annular welding is performed between the through hole 211 of the collector p...

Embodiment 2

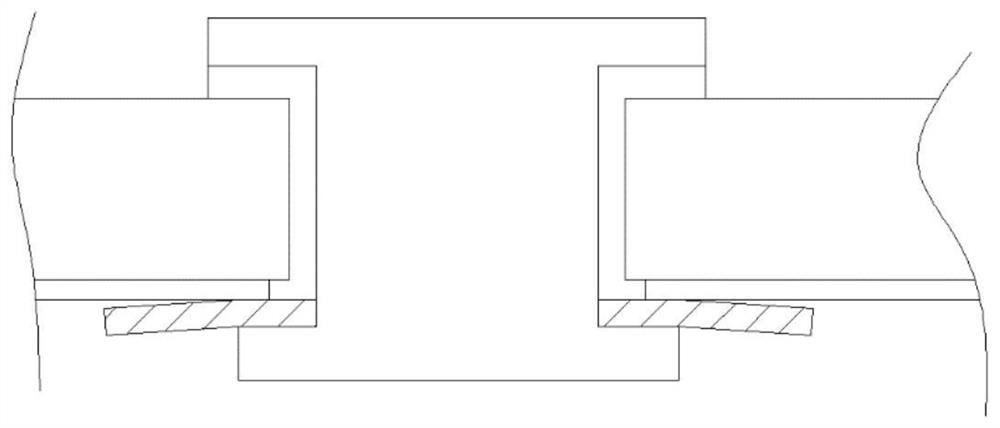

[0058] refer to Figure 5-Figure 10 ,and Figure 12-Figure 17 , the embodiment of the present invention provides a battery, including a casing 11 and a battery cell 12 arranged in the casing 11, and the two ends of the battery cell 12 are respectively provided with a positive electrode current collecting structure 30 and a negative electrode current collecting structure 40, and the positive electrode current collecting structure 30 adopts the battery current collecting structure provided in Example 1.

[0059] The positive electrode potential of the battery is high, so that the current passing through the positive electrode is large, which has a great test on the internal resistance of the current collecting structure at the positive electrode and the current conduction efficiency, especially in the process of charging and discharging with a large current. The current structure is prone to heat generation, and the current conduction efficiency cannot meet the requirements of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com