Heart valve prosthesis and heart valve prosthesis system

A technology for artificial heart valves and protruding parts, which is applied in the field of artificial heart valves and artificial heart valve systems, and can solve problems such as paravalvular leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

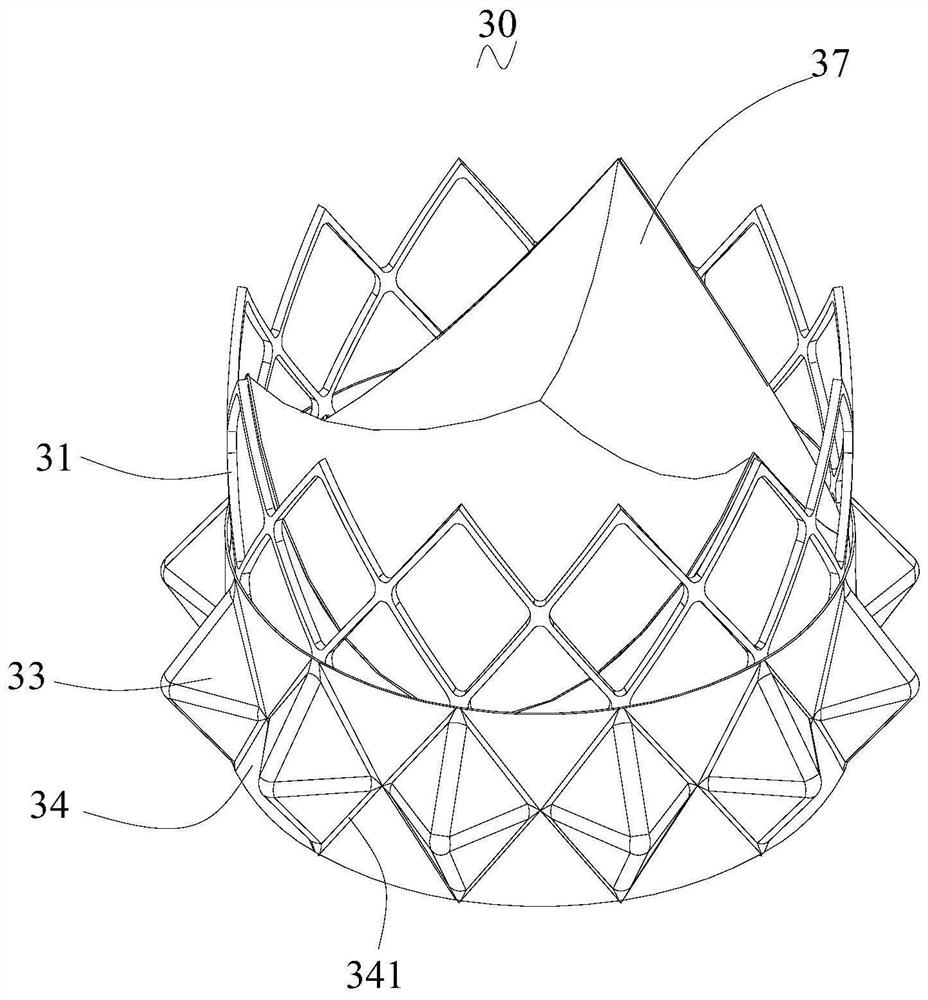

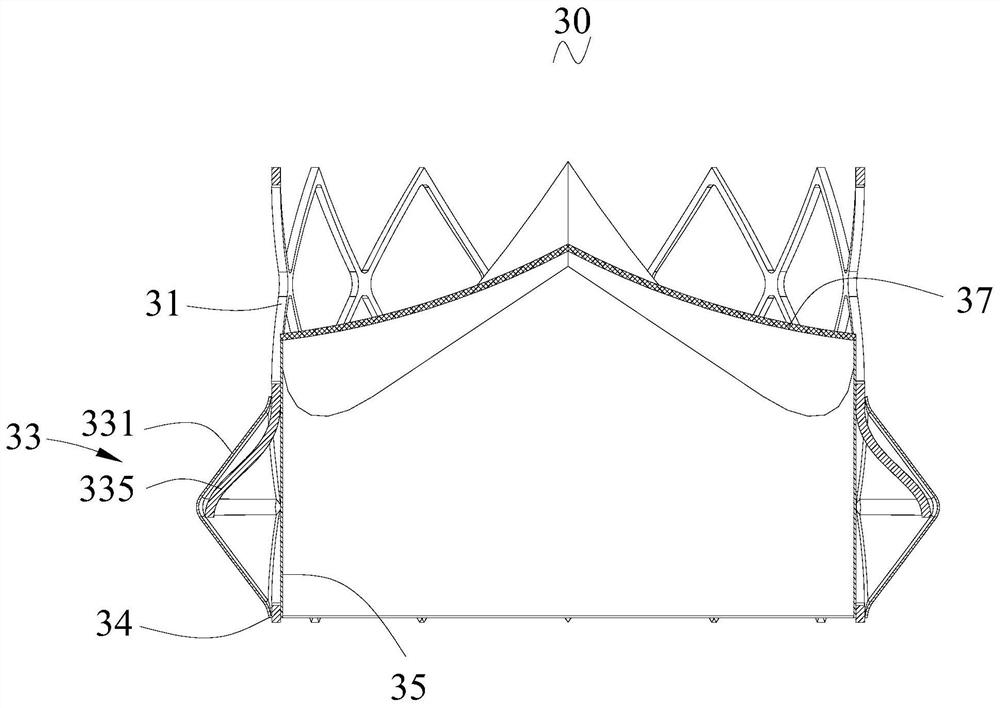

[0035] see figure 2 with image 3 , an embodiment of the present invention provides an artificial heart valve 30 , including a valve frame 31 , at least one protruding structure 33 , an inner skirt 35 and leaflets 37 .

[0036] The inner skirt 35 is fixed on the frame of the unit cell 312 by sewing, and the inner skirt 35 is positioned at the inner side of the petal frame 31. The inner skirt 35 can be made of PET (Polyethylene Terephthalate, polyester resin), PTFE (Poly TetraFluoroethylene, It should be noted that the "blocking" in this embodiment refers to preventing the blood from penetrating from one side to the other.

[0037] The contour of the distal end of the inner skirt 35 is trimmed according to the contour of the distal end of the valve frame 31, and the contour of the proximal end of the inner skirt 35 can be trimmed according to the contour of the proximal end of the valve frame 31 or directly adopts a flat mouth.

[0038] see Figure 4 with Figure 5 The pet...

no. 2 example

[0053] The number of protruding structures 43 in the second embodiment is multiple, wherein at least one protruding structure 43 includes a plurality of elastic pieces 435, and a part of the elastic pieces 435 of the multiple elastic pieces 435 of the protruding structure 43 are connected to the The proximal end is connected, and another part of the elastic member 435 is connected with the distal end of the cell. In the compressed state, there is an axial distance between the elastic member 435 connected to the proximal end of the unit cell and the elastic member 435 connected to the distal end of the unit cell, so that the protruding structure 43 is radially compressed to produce a circumferentially extending folds.

[0054] The number of elastic members 435 of each protruding structure 43 is two for illustration. Specifically, see Figure 9 with Figure 10 , in this embodiment, the number of elastic members 435 of each protruding structure 43 is two. Certainly, in other ...

no. 3 example

[0058]The difference between the third embodiment and the second embodiment is that, in the compressed state, there is a circumferential distance between the elastic member 535 connected to the proximal end of the unit cell 312 and the elastic member 535 connected to the distal end of the unit cell 312 , and there is no axial gap between the two elastic members 535 , and in the compressed state, the protruding structure 53 can produce folds 532 that bend and extend. It should be noted that the fact that the two elastic pieces 535 have no axial gap means that the free end of one elastic piece 535 is located within the axial length interval of the other elastic piece 535 .

[0059] see Figure 11 , in this embodiment, the sum of the lengths of the two elastic members 535 is greater than the axial length of the mesh 313, so that the two elastic members 535 do not have an axial gap, and the ends of the two elastic members 535 are set aside from each other. The protruding structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com