Rod-shaped article loading device for tray loader

A loading device and tray loading machine technology, applied in loading/unloading, conveyors, transportation and packaging, etc., can solve the problems of slow feeding speed, easy damage to rod-shaped items, difficulty in adapting to high-speed production requirements, etc., to achieve the following The effect of fast material speed, avoiding excessive or too small local air pressure, and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

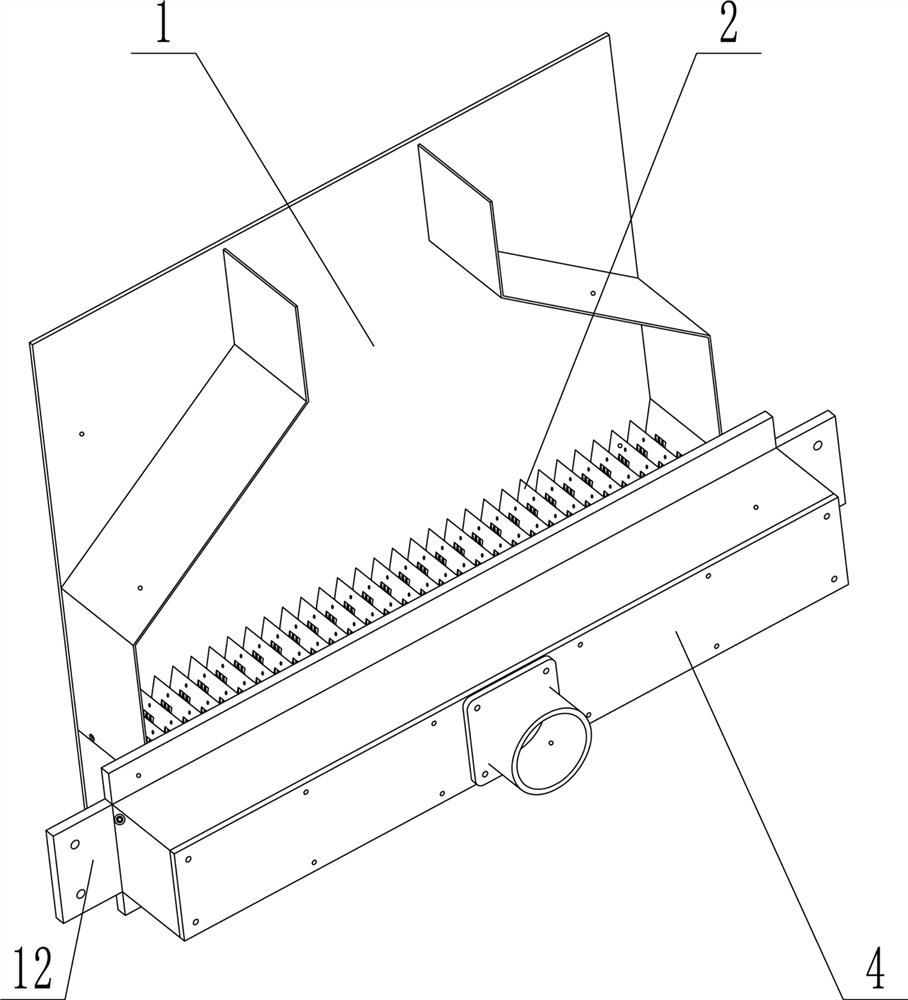

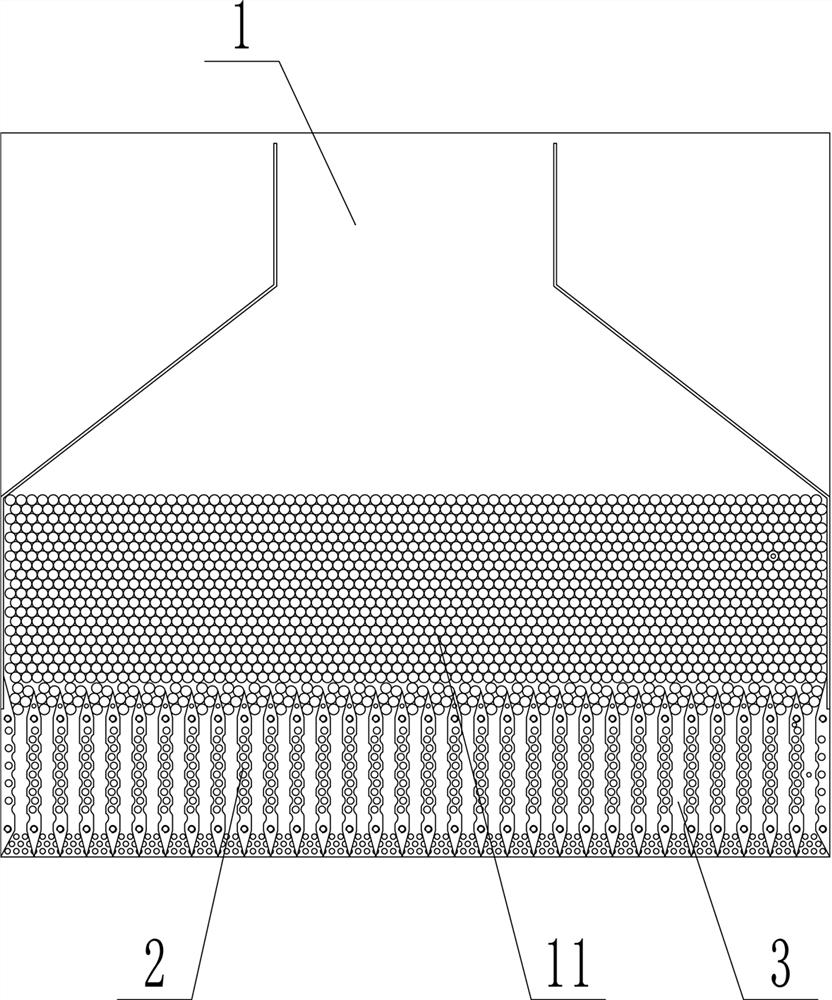

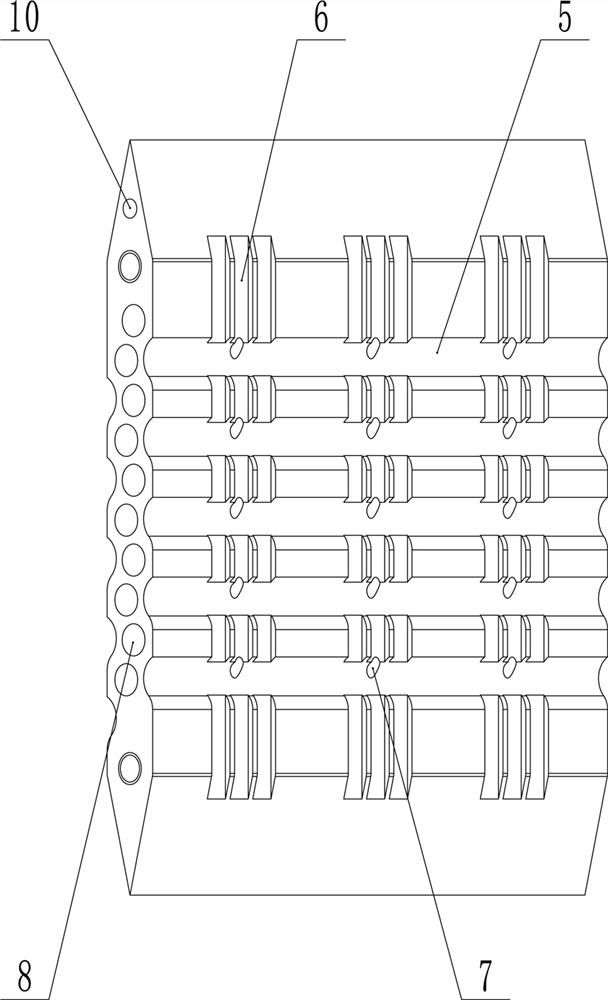

[0022] Such as Figure 1-6 As shown, a rod-shaped article loading device for a tray loading machine includes a warehouse 1, several vertical partitions 2 and air boxes 4 arranged at intervals at the bottom of the warehouse 1, and two adjacent vertical partitions A single-rod feeding channel 3 is formed between the plates 2, and the side walls of each vertical partition 2 are provided with multiple transverse grooves 5 extending in the front-rear direction and multiple airflow grooves extending in the up-down direction 6. At the intersection of each of the transverse grooves 5 and the airflow groove 6, there is a ventilation hole 7 facing obliquely downward, and there is a ventilation hole in the vertical partition 2 that communicates with the ventilation hole 7. The air box 4 is provided with a blowing chamber communicating with the blow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com