Inspection robot system construction method based on distributed hardware architecture

A technology for inspection robots and hardware architecture, applied in the field of intelligent robots, can solve problems such as heavy task workload and overall performance interference of robots, and achieve the effects of removing errors, facilitating data and clock synchronization, and facilitating system expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

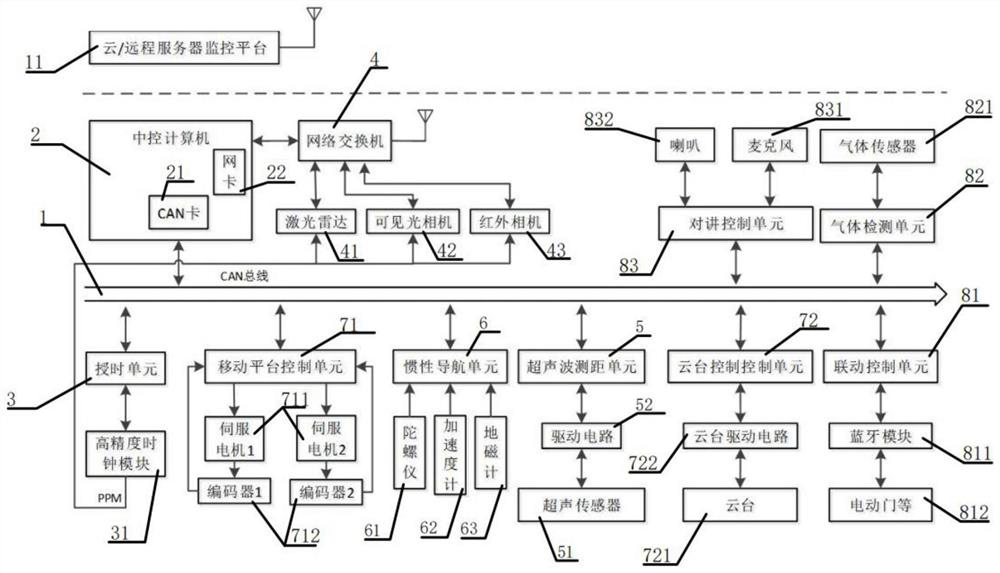

[0033] A method for constructing an inspection robot system based on a distributed hardware architecture, comprising the following steps:

[0034] Step 1, configure the central control computer 2 and the timing unit 3 based on the CAN bus 1; the central control computer 2 accesses the CAN bus 1 through the built-in CAN card 21; the timing unit 3 is mounted on the CAN bus 1;

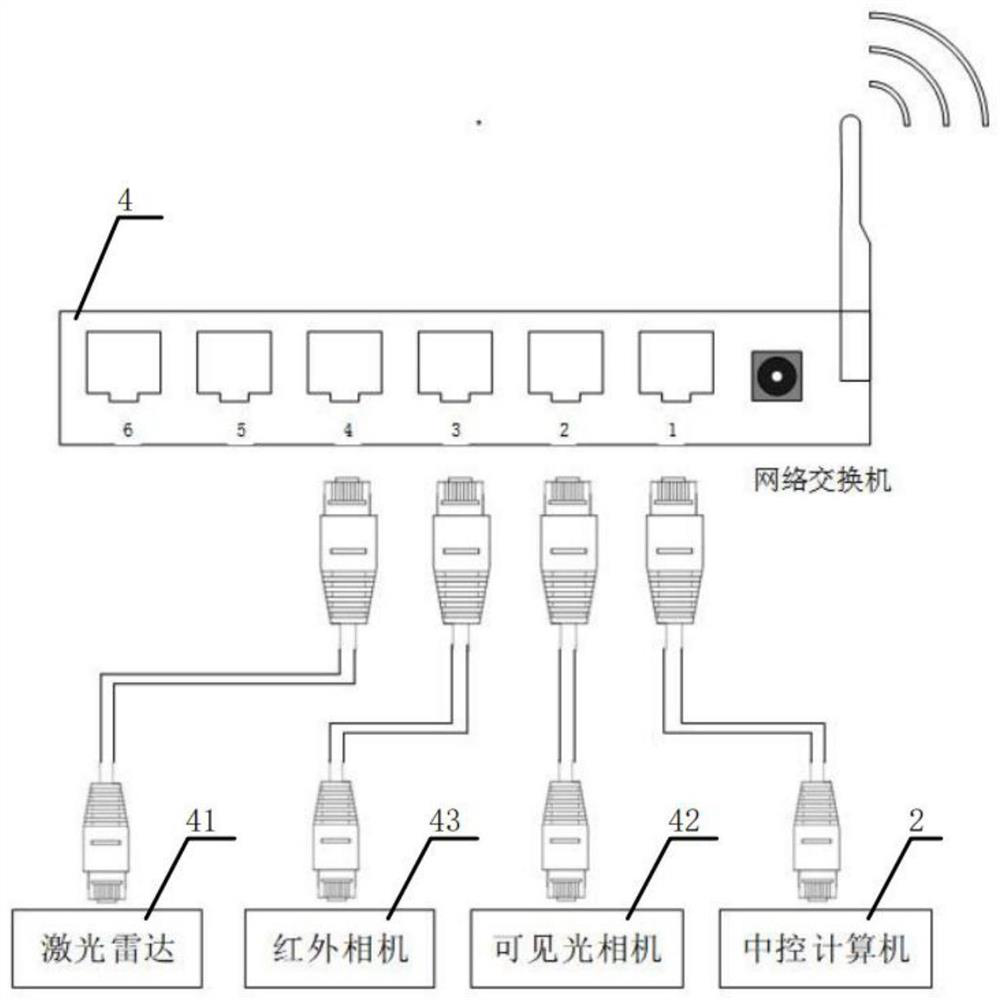

[0035] Step 2, configure the network interaction module based on the network bus; the configuration method of the network interaction module is: the network interaction module includes a network switch 4; the central control computer 2 is connected to the public network of the network switch 4 through the built-in network card 22 port, and carry out wireless communication with the remote monitoring platform 11;

[0036] Step 3, the network device group based on the network bus configuration hardware timing; the configuration method of the network device group includes:

[0037] S31, configure the percept...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com