High-performance rotor based on electric transmission system

A high-performance, electric drive technology, applied in electric components, electrical components, electromechanical devices, etc., can solve the problems of poor rotor high-speed performance, high rotor eddy current loss, poor assembly process, etc., to improve mechanical strength, improve performance, improve The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

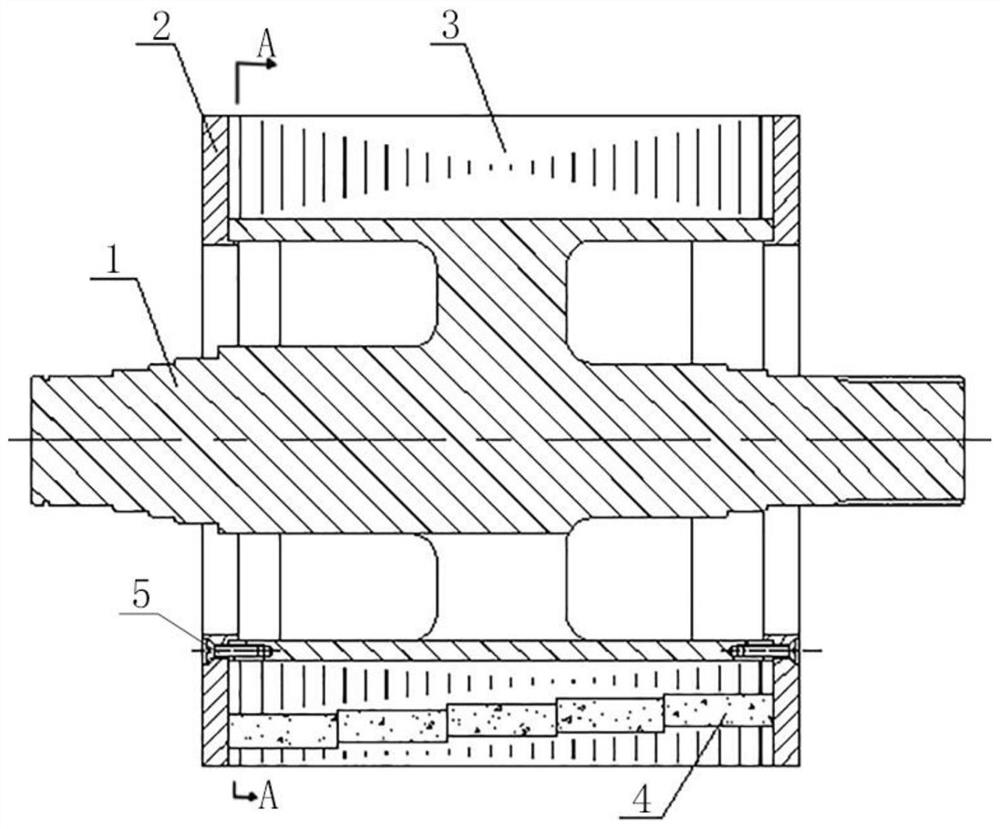

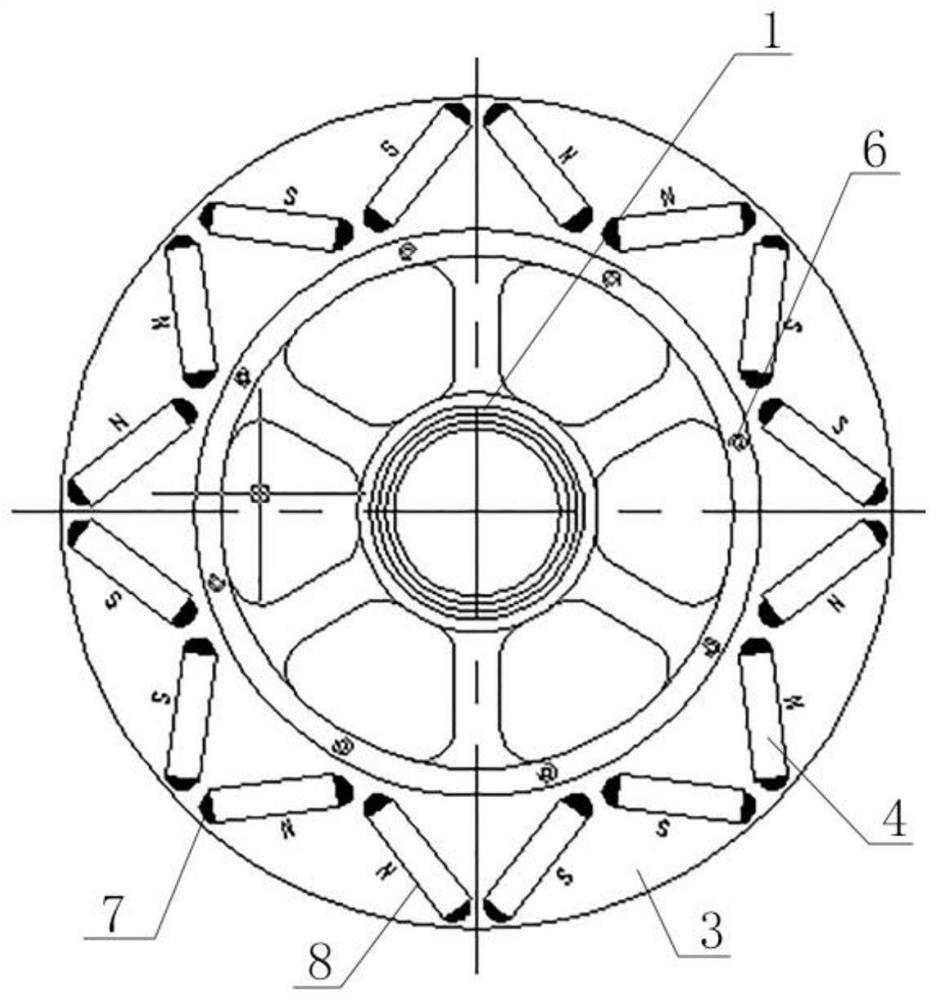

[0027] Such as Figure 1-7 As shown, a high-performance rotor based on an electric transmission system includes a rotating shaft 1, a rotor baffle 2 and a rotor core 3. After the rotating shaft 1 is sleeved with several sections of rotor core 3, and the rotor baffle 2 is used to separate The two ends of the three groups of fixed rotor cores are optimized to reduce the cogging torque and pulsation of the entire electrical system and improve the performance of the entire system by optimizing the structural performance parameters of the high-speed drive motor rotor used in the electric drive system.

Embodiment 2

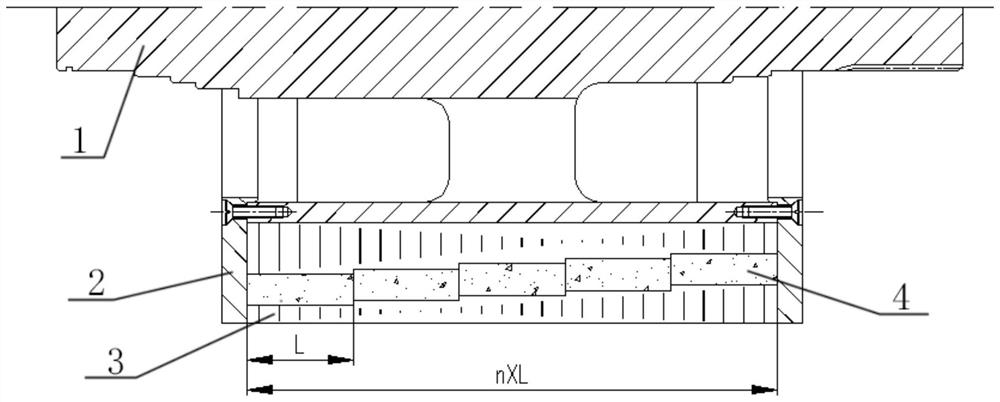

[0029] On the basis of Embodiment 1, the rotor core 3 is a silicon steel sheet with a ring structure, and magnetic steel grooves 8 are equidistantly arranged on the ring surface, and permanent magnets 4 are arranged in the magnetic steel grooves 8, and the permanent magnets 4 are placed in the Segmentation of the substrate state can effectively reduce the eddy current loss of the permanent magnet 4, reduce the motor loss, and improve the motor efficiency and magnetic field weakening capability.

Embodiment 3

[0031] On the basis of Embodiment 2, the length of the permanent magnet 4 corresponds to the thickness of the rotor core 3, and the entire rotor is segmented into n block, and install the magnetized permanent magnet 4 into the magnetic steel groove 8, which effectively improves the manufacturability of rotor assembly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com