High-bearing-capacity metal roof

A metal roof and high load-bearing technology, which is applied to roofs, roof cladding, and roofs using flat/curved panels, etc., can solve the problems of single limitation of applicable environment and weak bearing capacity, so as to improve the scope of application, offset deformation, and facilitate The effect of teardown detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

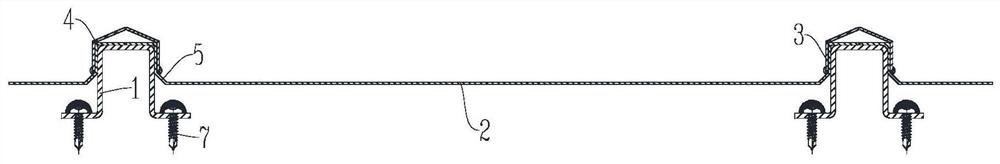

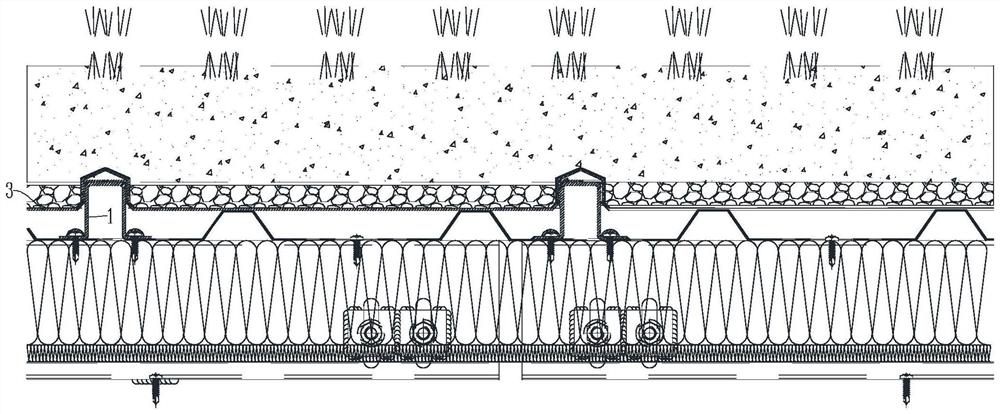

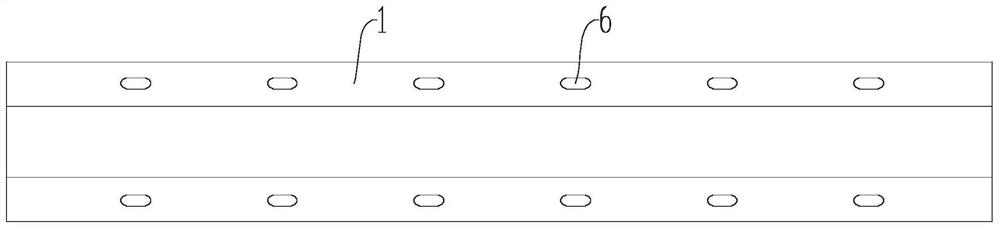

[0022] figure 1 , figure 2 and image 3 A high-load-bearing metal roof is shown, which includes a stainless steel bar 1 installed on the roof. The upper end of the stainless steel bar 1 is provided with two stainless steel panels 2. The cover plate 3 and the connection ends on both sides of the stainless steel panel 2 are fixed by continuous sealing welding. The two ends of the stainless steel panel 2 have upwardly bent side assembly flanges 4, and the side assembly flange 4 and the connection end of the stainless steel panel 2 have a structure for preventing The oblique bending section 5 that expands with heat and contracts with cold, the lower ends of bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com