Automobile electric glass emergency opening system and using method

A window glass, electric technology, applied in the direction of engine, elastic engine, machine/engine, etc., can solve the problems of low transmission efficiency, control power failure, circuit short circuit, etc., to achieve the effect of high transmission efficiency, reliable action and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

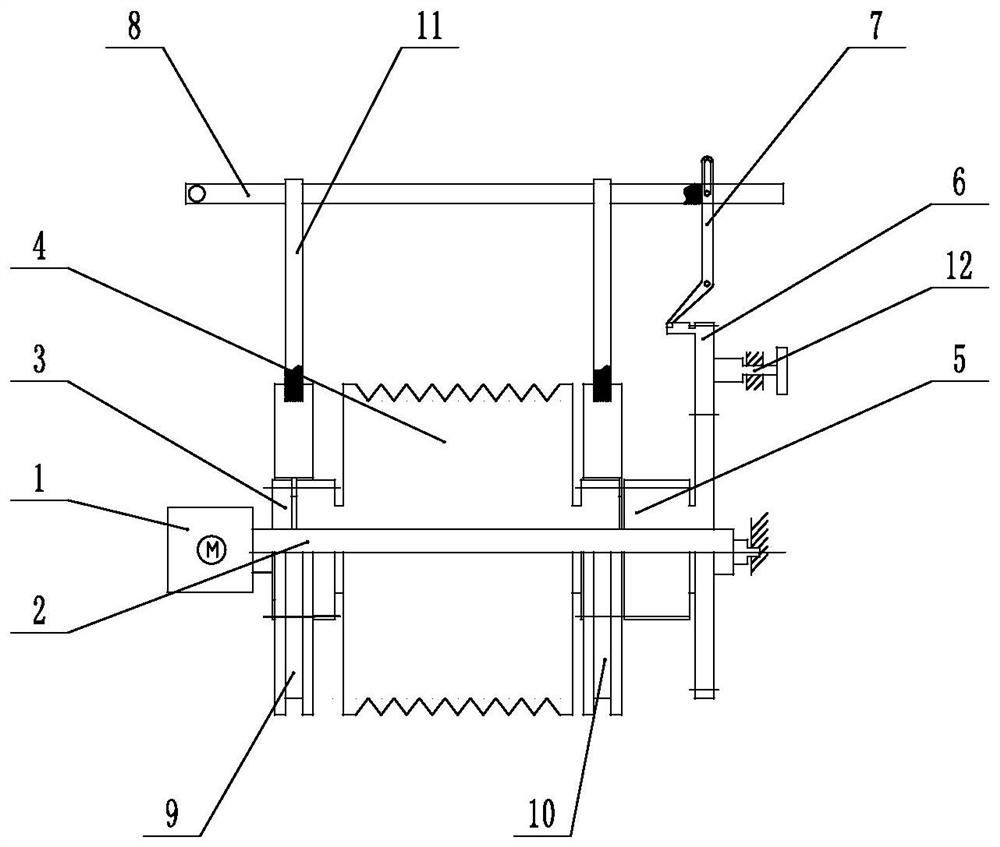

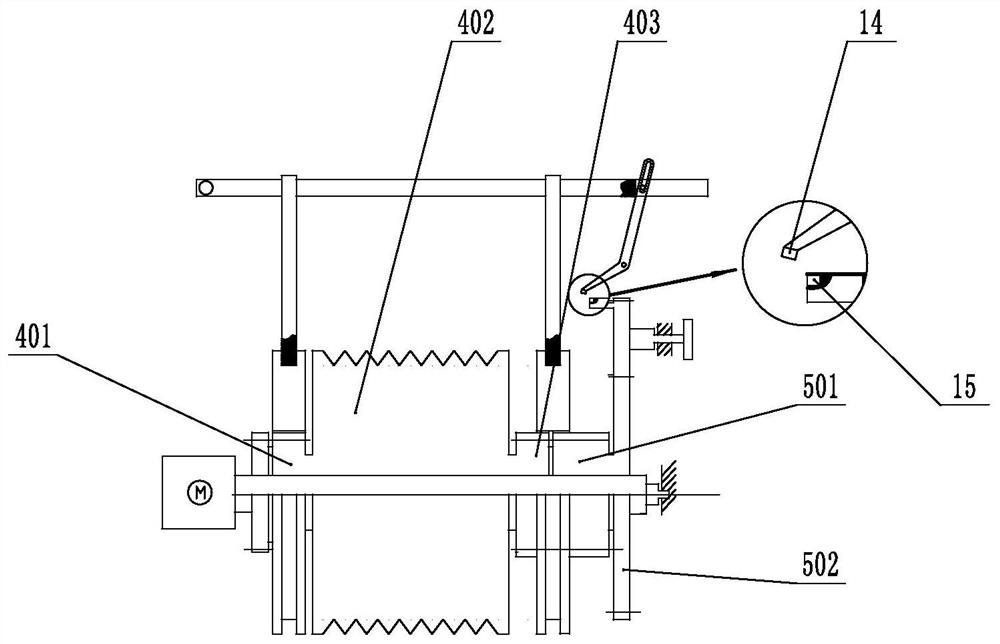

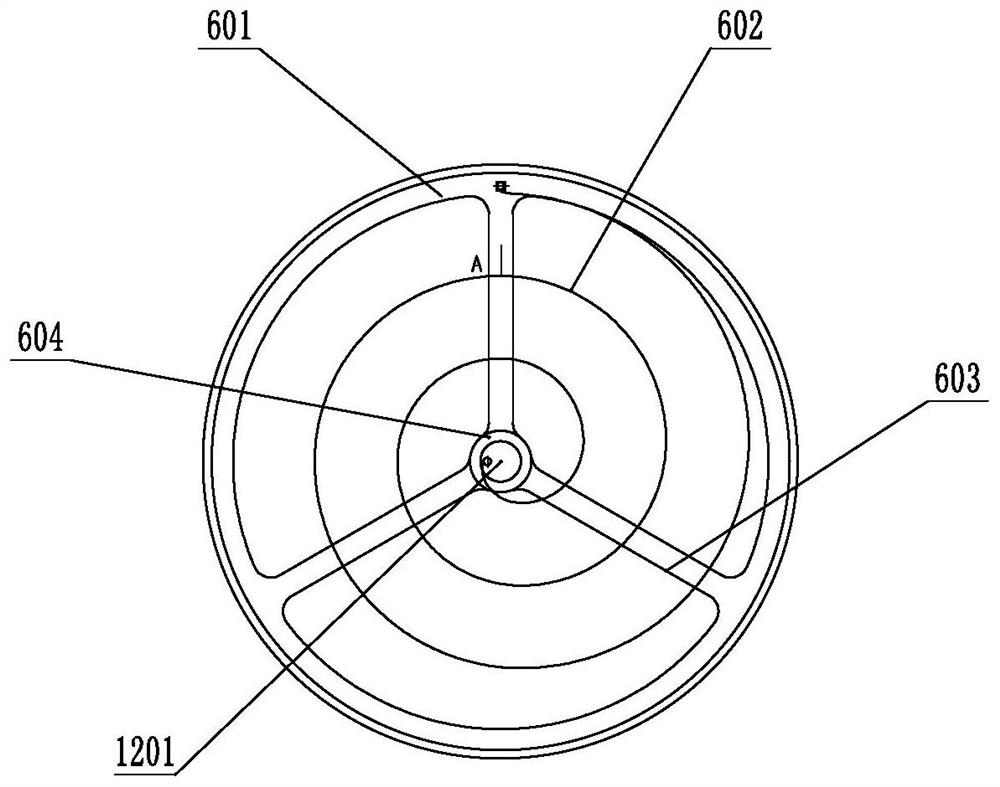

[0048] Such as Figure 1-6 As shown, a system for emergency opening of electric glass for automobiles includes a window glass 16, a jacking mechanism located below the window glass 16, and a power mechanism that provides power for the jacking mechanism. The power mechanism includes the reduction motor of the original electric glass 1. The power mechanism also includes a motor output shaft 2, a motor gear 3, a power output assembly 4, a transmission assembly 5, an energy storage gear 6 and a V-shaped limit rod 7. The motor output shaft 2 is connected to the output end of the reduction motor 1, and the motor The gear 3, the power output assembly 4 and the transmission assembly 5 are arranged on the motor output shaft 2, the motor gear 3 meshes with the motor output shaft 2, and the power output assembly 4 includes a joint gear I 401 connected coaxially, a power output wheel 402 and a joint gear Ⅱ403, the transmission assembly 5 includes coaxially connected transmission gear Ⅰ501...

Embodiment 2

[0060] Such as Figure 8 As shown, the jacking mechanism of this embodiment is different from that of Embodiment 1. The jacking mechanism of this embodiment is a steel wire cable jacking mechanism 19, including a support rod I1901, a support rod II1902, a fixed bracket II1903, a fixed bracket III1904, a wire rope 1905, two fixed pulleys 1906, slider 1907 and slider guide rail 1908, support rod I 1901 and support rod II 1902 are cross-hinged, and the bottom edge of the window glass 16 is provided with a glass installation guide rail 17 (this is the conventional structure of the window glass 16 ), the upper ends of the support rod I1901 and the support rod II1902 are slidingly arranged in the glass installation guide rail 17, the lower end of the support rod I1901 is hinged on the fixed bracket II1903, and the fixed bracket II1903 is fixedly connected with the vehicle body; the lower end of the support rod II1902 is hinged on the fixed bracket On III1904, the fixing bracket III1...

Embodiment 3

[0063] A method for using the emergency opening system for electric glass of an automobile according to Embodiment 1, comprising the steps of:

[0064] (1) Initial state setting: Take the gear sleeve I9 to connect the motor gear 3 and the gear I401 for linkage, the gear sleeve II10 is engaged with the gear II403, and the gear sleeve II10 is separated from the transmission gear I501; set the V-shaped limit lever 7 is connected with the limit block to limit the position of the energy storage gear 6; at this time, after the reduction motor 1 is started, the power output wheel 402 drives the active lever 1801, and the active lever 1801 rotates up and down with the fulcrum 1804 as the center of the circle, and the driven lever 1802 cooperates with the active lever 1801. The rod 1801 moves so that the window glass 16 can be lifted normally;

[0065] (2) Energy storage: remove the locking gear 1204 from the gear hole I 1205, unlock the energy storage handle 1202, turn the energy stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com