Integrated pipe solar water heater with heat collection as circulating power

A solar water heater and circulating power technology, which is applied to solar thermal collectors, solar thermal collectors using working fluids, solar thermal energy, etc., can solve problems such as affecting the sealing and strength of cylindrical water storage tanks, affecting the strength of water storage tanks, etc. , to achieve the effect of reduced product cost, small production workshop area and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

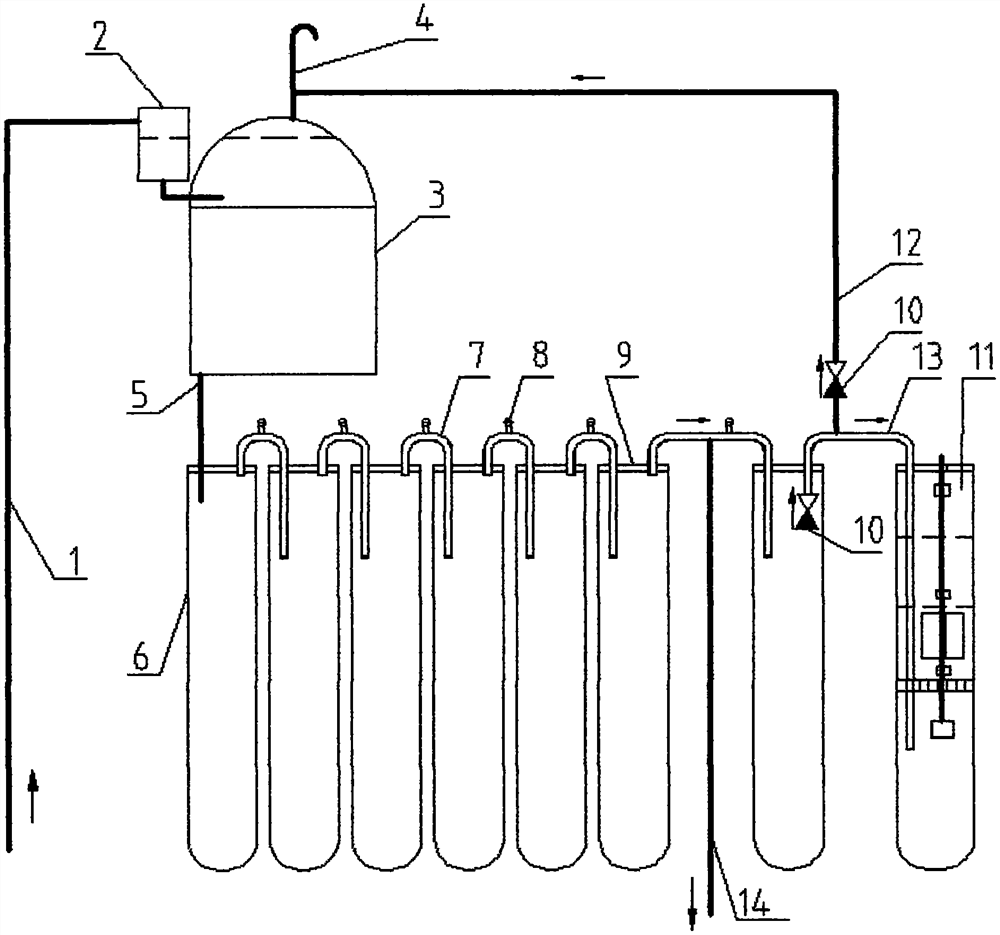

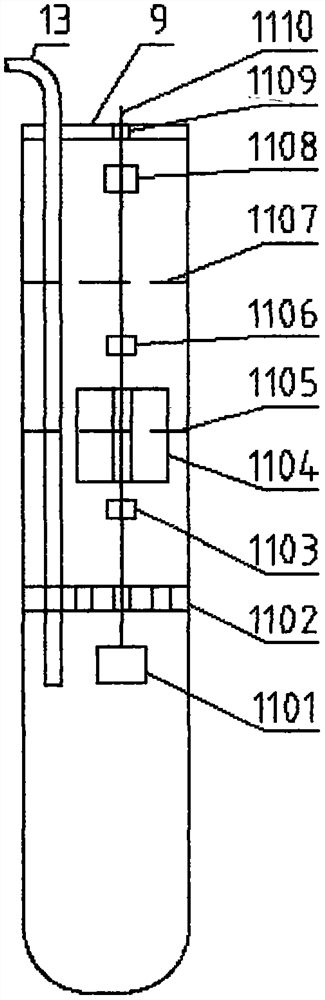

[0015] Ten large-diameter heat-collecting and water-storage integrated devices 6 are connected side by side to form a heat source absorber. The heated water enters the liquid level controller 2 through the water supply pipe, and then enters the water storage tank and the heat-collecting and water-storage integrated device 6 in turn. , and finally enter the heat collecting power device 11. The structure of the heat collecting power device 11 is a double-layer vacuum body composed of inner and outer layers, with a diameter of 280 mm and a height of 1200. The maximum liquid level 1105 of the heat collecting power device 11 is lower than that of the liquid level controller 2 The liquid level is 600mm-700mm. As a power source for driving water to circulate, it can also play a role in collecting heat for water; the integrated heat collection and water storage device 6 is a double-layer vacuum body composed of inner and outer layers, with a diameter of 200mm. The height is 1200, which...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com