Optical protection structure of small-spacing LED screen module and manufacturing process

An LED screen and optical protection technology, applied in optics, optical components, identification devices, etc., can solve the problems of small investment and prolong the life cycle of small-pitch LED screen modules, and achieve low investment, improved protection performance, and high contrast. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

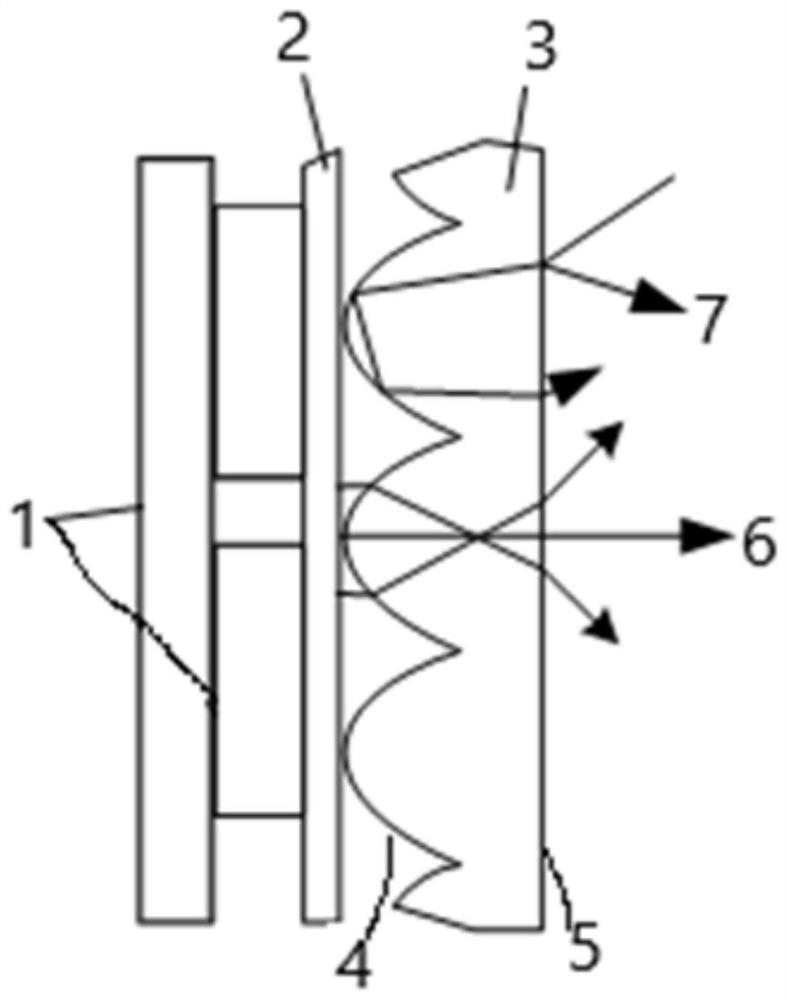

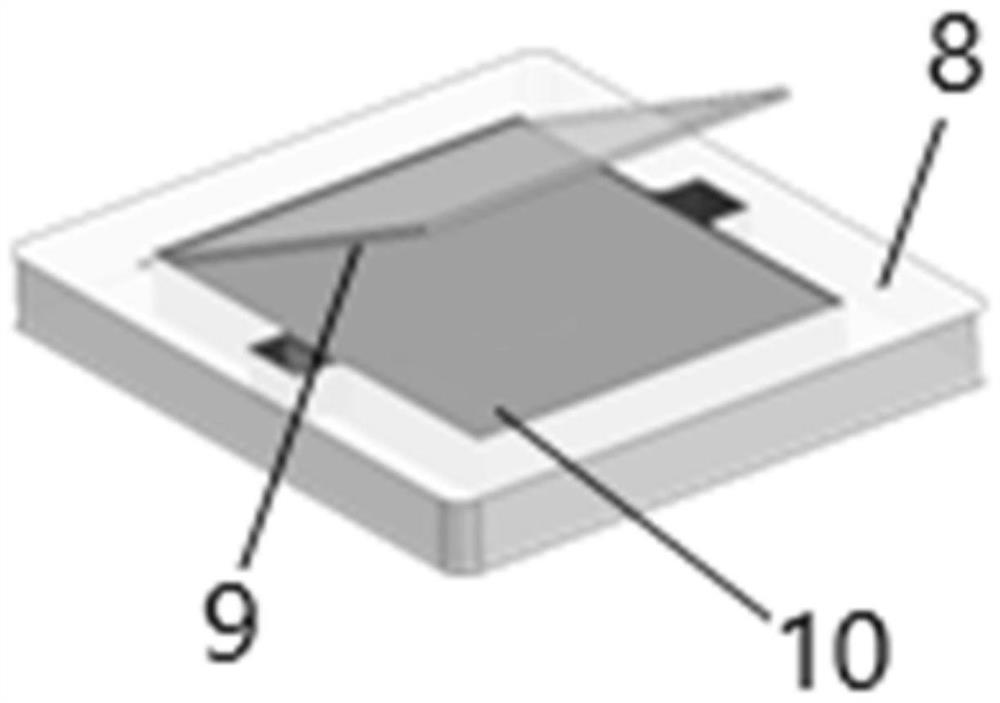

[0032] see Figure 1-Figure 2 ,

[0033] An optical protection structure of a small-pitch LED screen module of the present invention includes a SOM module, the surface of the SOM module display screen is pasted with an optical screen through an optically transparent colloid, and the optical screen includes a plane part and several cylindrical lenses structure, the several lenticular lens structures are located inside the optical screen; adjacent to the surface of the SOM module display screen, the plane part is located outside the optical screen.

[0034] Wherein, the protruding direction of the several lenticular lens structures is the direction perpendicular to the surface of the SOM module display screen; the several lenticular lens structures and the plane part are integral structures.

[0035] A manufacturing process of an optic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com