Talus fusion surface type artificial ankle joint prosthesis

An ankle, surface-type technology, used in ankle joints, prostheses, joint implants, etc., can solve the problem of difficult to achieve effective fusion of autologous bone and metal prosthesis, and achieve the effect of improving the fusion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

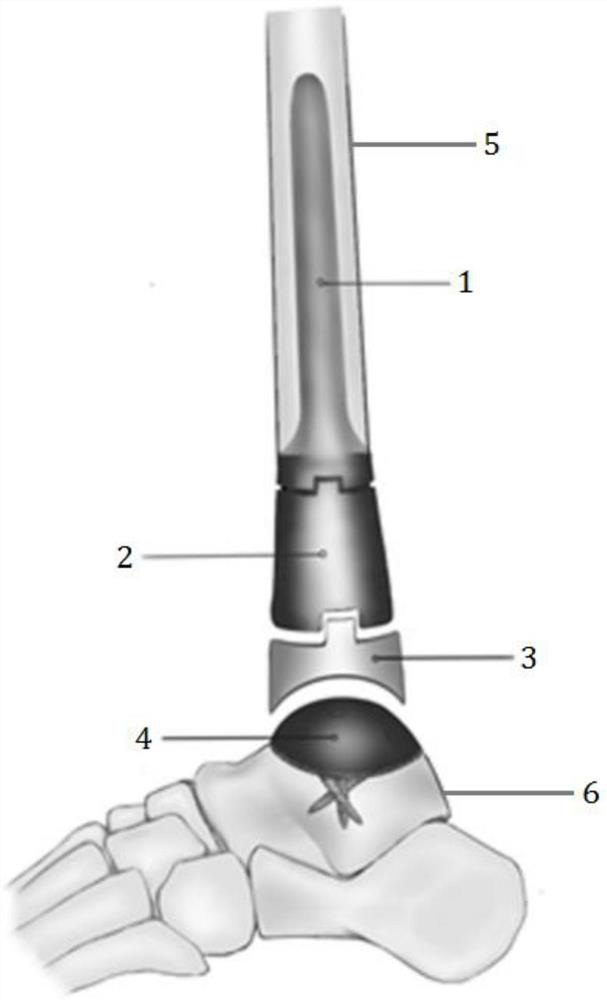

[0029] figure 1 A tumor-type talus fusion surface-type artificial ankle joint prosthesis is shown, which is mainly suitable for reconstruction of bone defects in limbs with interrupted continuity after distal tibial tumor resection. The tumor-type talus fusion surface-type artificial ankle joint prosthesis includes: tibial bone marrow The prosthetic stem 1 is fixed in the tibial medullary cavity, and the upper end of the prosthetic stem 1 fixed in the tibial medullary cavity is used for fastening connection with the tibial medullary cavity 5; the prosthesis segment 2 is conically connected to the lower end of the prosthetic stem 1 fixed in the tibial medullary cavity ; the joint liner 3 is embedded in the lower end of the prosthesis segment 2, and the lower surface of the joint liner 3 is a concave arc surface structure; the talar surface prosthesis 4, the lower part of the talus surface prosthesis 4 is tightly connected with the talus 6, The upper surface of the talar surface...

Embodiment 2

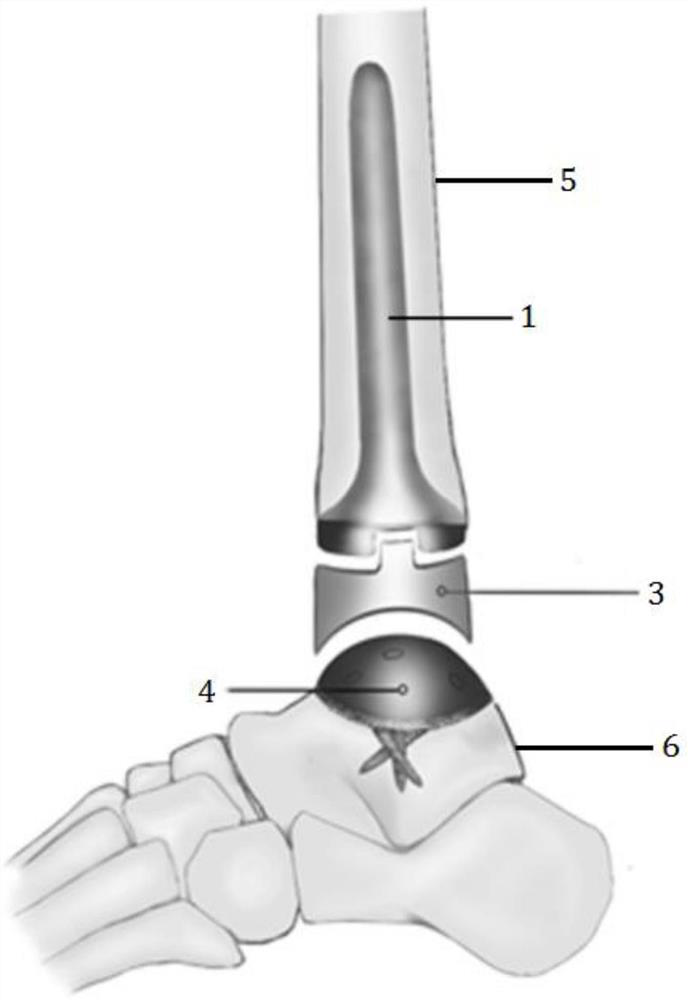

[0036] figure 2 A surface-replacement talar fusion surface-type artificial ankle prosthesis is shown, which is mainly suitable for ankle joint injuries, rheumatoid arthritis and other cases. The surface-replacement talar fusion surface-type artificial ankle joint prosthesis includes: tibial medullary cavity The internal fixation prosthesis handle 1, the upper end of the fixed prosthesis handle 1 in the tibial medullary cavity is used for fastening connection with the tibial medullary cavity 5; The lower surface of the liner 3 is a concave arc surface structure; the talar surface prosthesis 4, the lower part of the talar bone surface prosthesis 4 is tightly connected with the talus 6, and the upper surface of the talar bone surface prosthesis 4 is a polished convex arc surface structure and is connected to the joint lining. The lower surface of the pad 3 is conformally matched to form a smooth motion joint, so that the plantar flexion and dorsiflexion functions of the tibiotal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com