Steel plate machining device and process for production of assembly type prefabricated steel structure

A processing device and assembly technology, applied in auxiliary devices, manufacturing tools, metal processing and other directions, can solve the problems of labor-intensive, limited use range, large gaps, etc., and achieve simple and convenient operation, flexible and convenient setting, and thick and firm structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

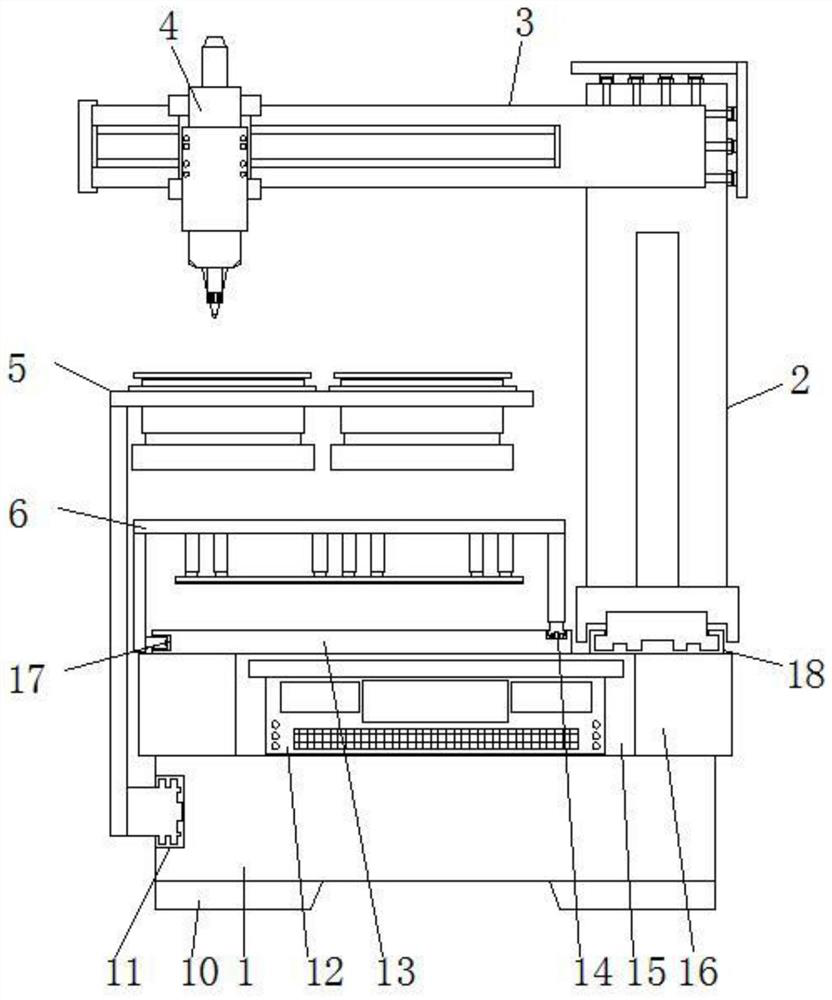

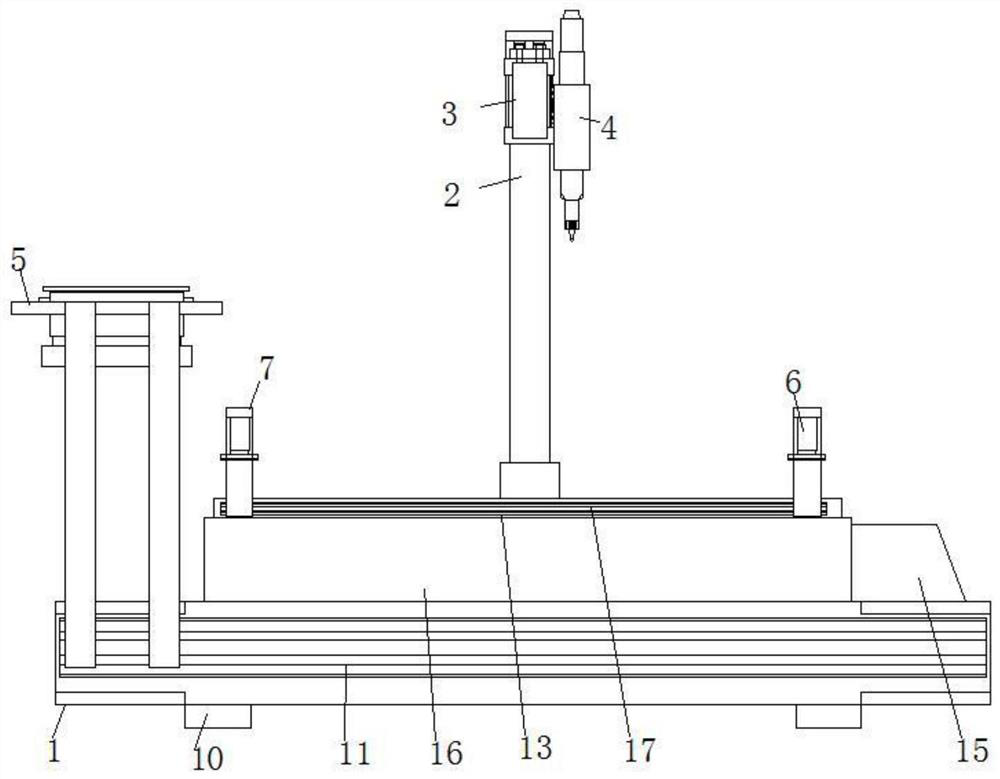

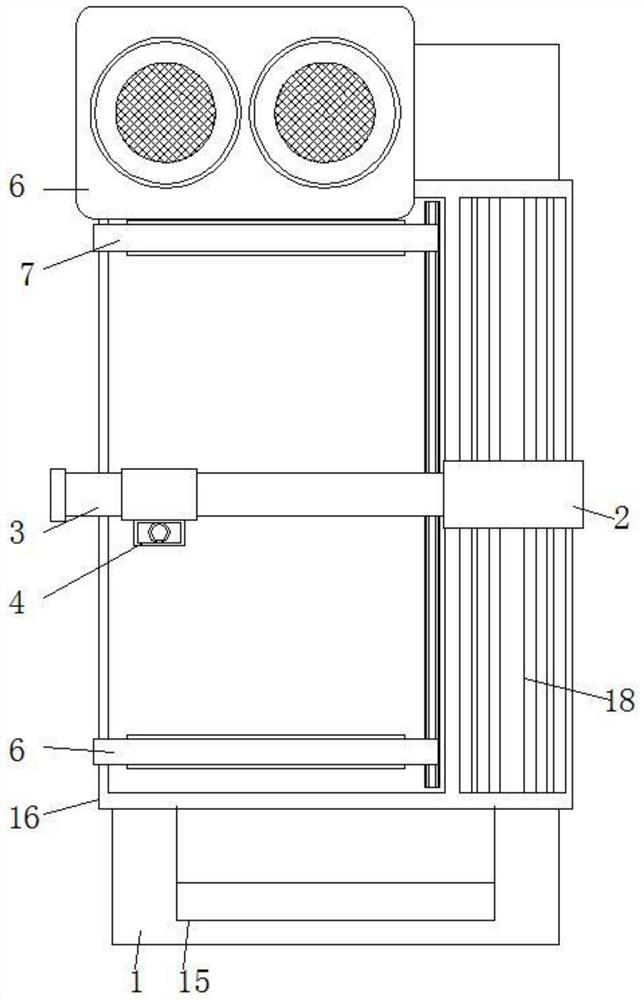

[0041] refer to Figure 1 to Figure 8 As shown, a steel plate processing device for the production of fabricated prefabricated steel structures, including: machine tool 1, lower frame 2, upper frame 3, laser cutting mechanism 4, dust suction mechanism 5, right pressing mechanism 6 and left pressing mechanism Mechanism 7; the upper end surface of machine tool 1 is provided with top seat 16, and the upper end surface left part of top seat 16 is provided with processing table 13, and right pressing mechanism 6 and left pressing mechanism 7 are arranged on processing table 13, simultaneously lathe 1 The first linear slide rail 11 is arranged on the left side of the left side, and the lower end of the ash suction mechanism 5 is slidably connected on the first linear slide rail 11, and the first ash collection box 8 and the first ash collection box 8 are installed on the top of the ash suction mechanism 5. The second ash collection box 9; the upper end face right part of the top sea...

specific Embodiment approach 2

[0042] Specific embodiment two, this embodiment is a further limitation to specific embodiment one, the top seat 16 structure that the upper end face of machine tool 1 is provided with among the present invention is thick and firm, and the processing table 13 that is provided with on top end face left of top seat 16 It is used for cutting and processing prefabricated steel materials. At the same time, a third linear slide rail 17 and a second linear slide rail 14 are respectively provided on the left side of the processing table 13 and the right end of the upper end surface for the lower ends of the right pressing mechanism 6 and the left pressing mechanism 7. Sliding connection is carried out to facilitate the horizontal movement of the right pressing mechanism 6 and the left pressing mechanism 7, and the setting is more flexible and convenient.

specific Embodiment approach 3

[0043] Embodiment 3. This embodiment is a further limitation of Embodiment 1. The fourth slider 24 at the lower end of the lower frame 2 in the present invention is slidably connected to the fourth linear slide rail 18 on the right side of the upper end surface of the top seat 16. , which is convenient for the lower frame 2 to move back and forth in the horizontal direction, thereby driving the upper frame 3 and the laser cutting mechanism 4 to move back and forth synchronously, so as to control the laser cutting position, and at the same time, the right part of the upper frame 3 is passed through multiple groups Fastening bolt is installed in the installation groove 20 of lower frame 2 upper left parts, makes detachable between upper frame 3 and lower frame 2, so that later stage equipment maintenance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com